DZL Single Drum Coal Fired Steam Boiler 1 Ton For Food Processing

Factory

Brief intrduction of coal fired steam boiler

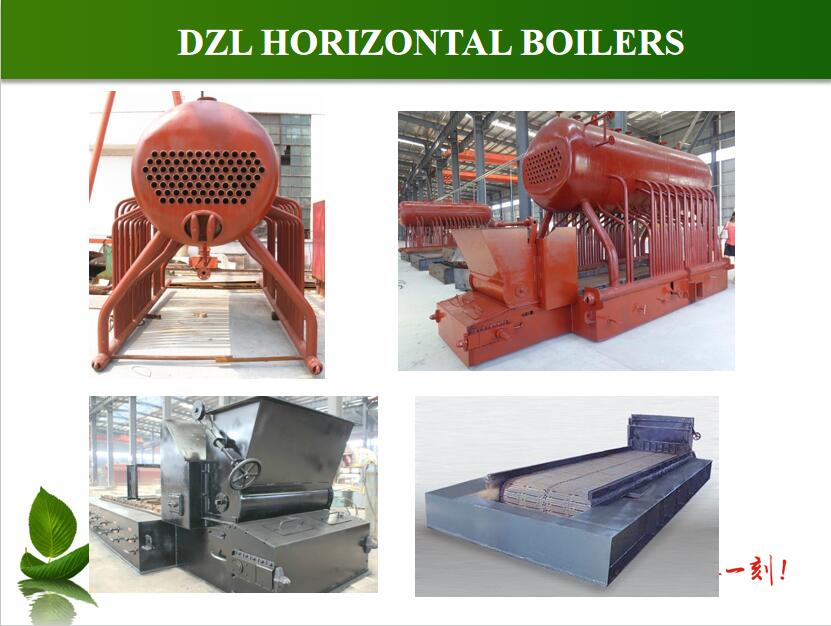

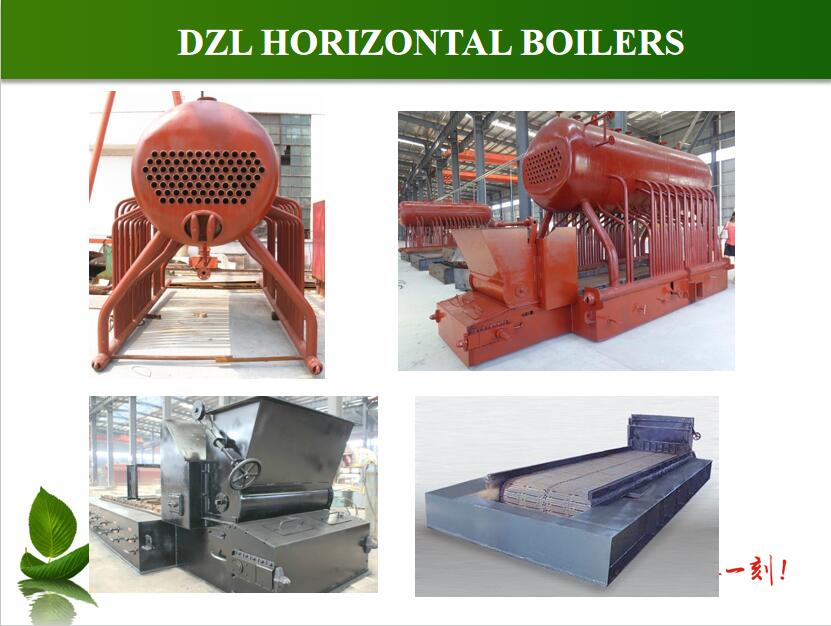

The DZL series boiler is single drum horizontal type automatic

feeding chain grate stoker, water-fire tube boiler. 1-6tph boiler

is package boiler and 6-35 tph is shop-assembled structure, which

is composed of 2 parts, upper part is heat surface and lower part

is combustion equipment. By adopting furnace arch, wing-shape flue

and threaded smoke tube design , the boiler have the advantages of

high thermal efficiency, sufficient output and wide coal

adaptability.

Quick Details of coal fired steam boiler

| Boiler Model | Rated capacity | Rated pressure | Rated Steam temp. | Active grate area | Boler efficiency | Fuel consumption |

| | t/h | MPa | ℃ | ㎡ | % | Kg/h |

| DZL1-1.0-AII | 1 | 1 | 184 | 1.85 | 80 | 118 |

| DZL2-1.25-AII | 2 | 1.25 | 194 | 3.4 | 80 | 238 |

| DZL4-1.25-AII | 4 | 1.25 | 194 | 5.18 | 80 | 472 |

| DZL6-1.25-AII | 6 | 1.25 | 194 | 7.55 | 80 | 685 |

| DZL10-1.25-AII | 10 | 1.25 | 194 | 12 | 80 | 1128 |

| DZL15-1.25-AII | 15 | 1.25 | 194 | 18 | 81 | 1698 |

| DZL20-1.25-AII | 20 | 1.25 | 194 | 22.9 | 81 | 2241 |

| DZL30-1.25-AII | 30 | 1.25 | 194 | 27.5 | 81 | 3380 |

| DZL40-1.25-AII | 40 | 1.25 | 194 | 34.5 | 81 | 4481 |

Coal fired steam boiler design features:

1.The boiler has big drum and have big enough space for water.

Compared with the SZL series, the DZL boiler is more adaptable to

poor water quality. Moreover , when the boiler scaled, it is

convenient for maintenance.

2. Adopting convex tube plate, prevent tube plate cracking and

simplify the structure of canceling the tension bar.

3. The Wing-shape flue arrangement, the flue gas is three pass,

reduce the smoke temperature of high temperature area tube plate,

thereby preventing the cracking of tube plate and Boiler tube

explosion.

4. Adopting threaded smoke-tube technology, strengthen heat

transfer, reduce the number of pipes and the size of boiler shell;

reduce the thermal stress at the end of the pipe, and prevent

cracking of the tube plate. At the same time, due to the

self-cleaning ability of the flue gas in the threaded pipe, avoid

the accumulation of dust in the tube.

Coal fired steam boiler application fields

- Food industry: such as rice mills, noodle factory, canned factory,

juice processing factory, tomato sauce factory, beer wine factory,

etc.

- Textile industry: textile factory, garment factory, sweater

factory, socks industry, dyeing factory.

- Petrochemical industry: steam can be used to heat oil, to

strengthen the liquidity of oil;Paper Mill: provide heat for

heating and dissolving, machine shaping, Black slurry concentration

and Squeeze drying of the chemicals in the pulping process.

- 4.Pharmaceutical industry. Steam for disinfection, rough washing,

fine washing, drying, cooling, preparation, granulation, tableting

and coating etc.

- Packaging industry: labeling machines, cardboard factory, carton

box factory, corrugated cardboard box production line.

- Foam, furniture production: the steam can be used for producing

foam. When making furniture, wood needs to be dried with steam;

- AAC block aerated concrete block, production:steam used for drying

the aerated brick;

- Washing ironing industry: generally used in laundry, including dry

cleaning machines, dryers, washing machines, dehydration machines,

ironing machines, iron and other equipment supporting the use;

Boiler system: we provide this coal fired steam boiler with full

set auxiliaries.

| Number | Item | Number | Item |

| 1 | Boiler proper | 8 | Induced fan |

| 2 | Coal feeder | 9 | Steam header |

| 3 | PLC Control Cabinet | 10 | Dust collector |

| 4 | Economizer | 11 | Deaerator |

| 5 | Water treatment | 12 | Chimney |

| 6 | Water tank | 13 | Slag remover |

| 7 | Forced fan | 14 | Instrument&valves |

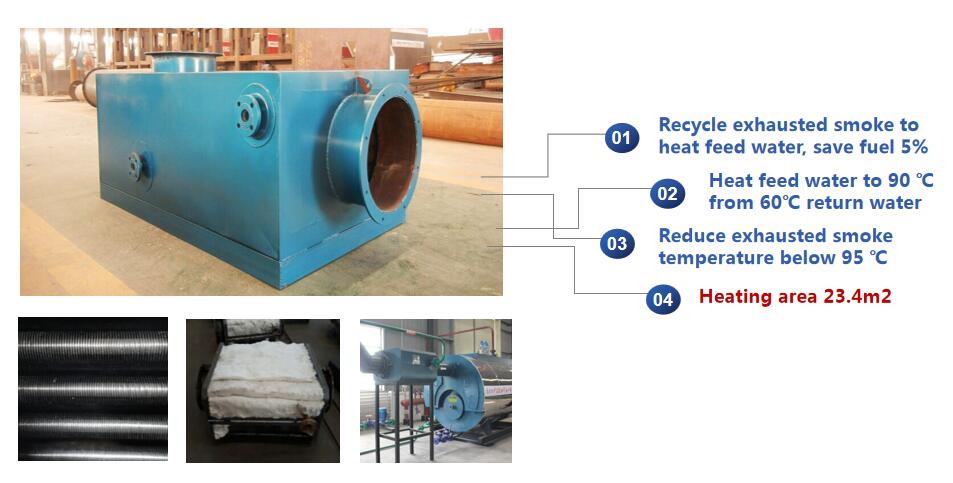

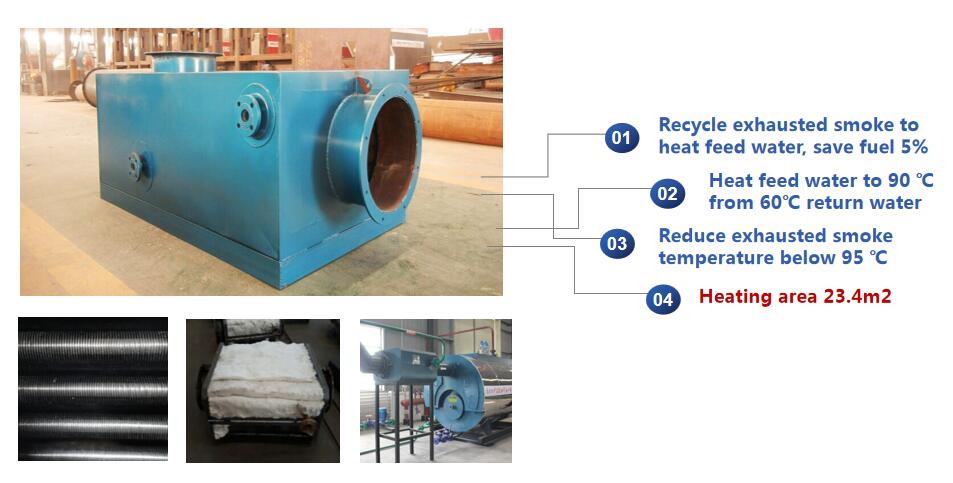

Economizer

Aluminium-steel Fins with high conductivity co-efficient.

ND steel sheel to prevent the corrosion of sulfur

Aluminium Silicate insulation, release heating loss, reduce

economizer outer cover temperature.

Large size heating area, adequate heating exchange area, greatly

make use of heat energy of exhausted gas to heat feed water,

increase boiler efficiency;

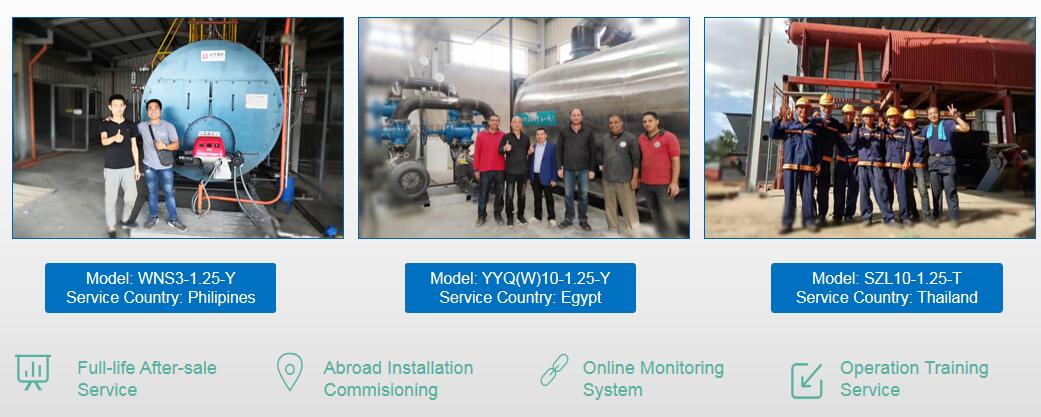

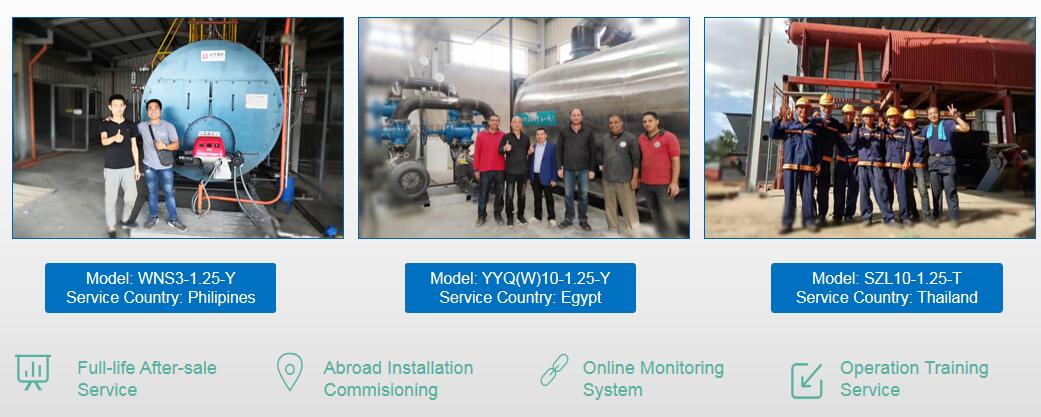

7.After-sale service:

1. provide full range of original spare parts.

2. We will send engineers to your local project site to guide the

installation and commissioning.

3. Our engineers will held a training for boiler workers to ensure

the safe operation.

4. Free maintenance and repair for one year and lifelong service.

8. FAQ

Q1: How can you get the best price quickly?

(1) We need to know the boiler capacity, the fuel you plan to use

and the steam pressure you need, and then we can confirm the boiler

model. (2) Customer needs to provide us your name, email address

and company name, and then we will send you price list

immediately.And if you use whatsapp, skype or wechat, you can

provide us your ID, it will be more convenient

for our communication.

Q2: Why should you believe our boiler quality?

(1).Strength calculation report with applied materials information;

(2).100%NDT(non-destructive inspection) report of steel plate, tube

and welding rod;

(3).100% X-ray inspection(welding seam): ensure the quality of

entire boiler;

(4).Hydrostatic test: ensure the standard working pressure and

safety;

(5).Third-party inspection report:By Henan Boiler Inspection

Institute;

(6).Passed ISO:9001 and SGS certificate.

Q3: What about the installation and Commissioning?

After you receive the boiler, we will guide you to make some

preparation for installation;If necessary, our expert will fly to

your local place in 72 hours. The experts will responsible for

guiding installation and commissioning.

But the buyer will be in charge of :

(1) The round air-tickets costs from Zhengzhou city to your project

site.

(2) Board and lodging of seller's workers for entire period at the

end user's site.

(3) Service fee for guiding engineer:100$/day/person.

Q4:What is the using life of your boiler?

A:Normally the boiler is designed for 20 years life span, but with

right operation and good maintenance,the boiler can be used for

20-25 years.