KOMEG Technology Ind Co., Limited |

|

Touch Screen Temperature test chamber / for high temperatures for rapid temperature cycling

KOMEG is proud to have available a budget friendly, high quality range of environmental testing chambers. KOMEG Technology has been manufacturing environmental test equipment since 1990 and specialises in climatic test chambers, thermal shock test chambers, walk-in chambers and medical laboratory equipment.

Komeg has been a specialist in environmental tests for almost 26 years and designs and manufactures chambers that can simulate extreme and reproducible environments. Present in sectors as diverse as automotive, aeronautics, space, defence and telecommunications, Komeg helps guarantee the best level of performance, reliability and safety for your products.

The KMH-L range is a -40°C to +150°C range of environmental chambers available in 5 sizes from 150L up to 1000L. This model features a large 7” full colour LCD touch screen controller capable of up to 120 programs or 1200 cycle steps. The programmable controller is easy to use and clear to read making operation simple and quick and designed with ease-of-use a priority.

Features:

Specifications

| Model | KMH-1500L | ||||

| 1500L chamber volume | |||||

| Temp. range | -40°C ~150°C | ||||

| Display resolution | 0.1°C | ||||

| Temperature stability | High±0.5°C ,low ±1.0°C | ||||

| Temperature uniformity | ±2.0°C | ||||

| Heat up time | -40°C ~+100°C,within 45 min | ||||

| Pull down time | +20°C ~-40°C,within 60 min | ||||

| Interior Dimension(mm) | W 1500 × D 1000 × H 1000 mm | ||||

| Exterior Dimension(mm) | About: W2010 x D1510 x H 2150 mm | ||||

| Interior material | Stainless Steel Plate ( SUS 304) | ||||

| Exterior material | Baked Painting Steel Or Stainless steel ( SUS304) | ||||

| Insulation material | Rigid polyurethane Foam and Glass Fiber Wool | ||||

| Total power | 7KW(heater 3KW included) | ||||

| Max current | 13.6A | ||||

| Ambient Temp. | +5°C ~+35°C | ||||

| Power Supply | AC 380V±10% 50Hz ,3 phase 4 wires +Ground Wires | ||||

| Weight | 420KG | ||||

| Sight window size | 430 X 530mm | ||||

| Sample holder | 2 pcs | ||||

| Fittings | cable port(portΦ50mm)*1, chamber lamp*1, power cable *2m | ||||

| Safety device (standard) | No fuse breaker,over pressure,over heat&over current protect,over temp. | ||||

| protect, over load protect for blower, dry heat protect | |||||

| Control System | Balanced Temperature & Humidity Control (BTHC)System | ||||

| Refrigeration system | Air Cooled (Water Cooled is option) | ||||

| Hermetic compressor | |||||

| Single stage refrigeration system, | |||||

| CFC-Free refrigerant(HFC-507/HFC-23) | |||||

| Controller | 7-inch LCD Touch Screen panel | ||||

| Operation model :Program or fix point running | |||||

| Memory capacity :120programs,1200steps, | |||||

| All repeat 999 cycles, part repeat 99 cycles | |||||

| Note: 1. We reserve the right to change specifications without

prior notice 2. Customized sizes and configurations available | |||||

Features

A. Reliability testing based on current test standards in the temperature range of -40 °C to 180 °C and 10% to 98% R.H.

B. The ideal simulation chamber for all heat and cold testing in the traditional temperature range -40 ºC and 150 ºC.

C. Forced ventilation loops design, balance temperature & humidity control system (BTHC).

D. We can provide custom-made machine and optional accessories satisfied your special requirements.

E. Improved programming and data collection via computer

F. Energy-saving operation, the KM-5166 controller uses advanced control of an electronic expansion valve to save energy and improve control of the refrigeration system. Improvements in refrigeration and heater operation make the new generation of KOMEG environmental test chambers the most energy efficient ever.

Standards Implemented and met

●GB10592-89 Technical requirements for high and low temperature

test chamber

●GB2423.1-1989 Low temperature test mode

●GB2423.2-1989 High temperature test mode

●GJB150.3-1986 High temperature test mode

●GJB150.4-1986 Low temperature test mode

●GJB150.9-1986 Warm test method

Standard configuration

●Stainless steel exterior

●Energy-efficient refrigeration with exclusive electronic expansion valve system

●Specialized humidity generation and control

●Unique thermal break construction for extreme testing

●Sight window*1, cable port(portΦ50mm)*1, shelves*2, chamber

lamp*1, power cable *2m

●No fuse breaker, over pressure,over heat and over current protection for compressor, Over

temperature protection, over load protect of blower, dry heat

protection

Optional accessories

●Cable Port: Φ100mm cable port is available

●Shelves

●Ro-type water purifier:R-80/day

Provide to keep the humidifying heater and wet bulb wick free from

scale.

●Inner glass door with operation port

A glass door can be provided behind the main door so that specimens

can be observed. Two operation ports of 130mm diameter are used for

handing specimens inside the chamber without opening the glass

door.

●Dehumidifier

The rotation regenerating dehumidifier M-120 ensures precise

control of low humidity (5℃ 5%RH) for electrostatic reliability

tests.

●Temperature and humidity recorder

Temperature 1 pen and humidity 1 pen.

Temperature 3 dots and humidity 1 dot.

Temperature 6 dots and humidity 6 dots.

●Defrosting circuit

The chamber automatically detects and melts the frost on the

evaporator when operating below 0℃.

●Liquid or infection

In order to rapidly decrease the temperature inside the chamber, a

cylinder of liquid can be connected the chamber

F. Energy-saving operation, the KM-5166 controller uses advanced control of an electronic expansion valve to save energy and improve control of the refrigeration system. Improvements in refrigeration and heater operation make the new generation of KOMEG environmental test chambers the most energy efficient ever.

| Minimum Order Qty: | 1 units |

| Price: | Negotiable |

| Payment Terms: | T/T, negotiable |

| Warranty | 12 months on parts (excluding the damages caused by the natural disasters, abnormal power, improper operation and maintenance, etc) |

| Delivery Time: | 60 working days after received 60% deposit |

| Packaging Details: | Packed in carton firstly, and then reinforced with plywood case for outer packing |

About KOMEG:

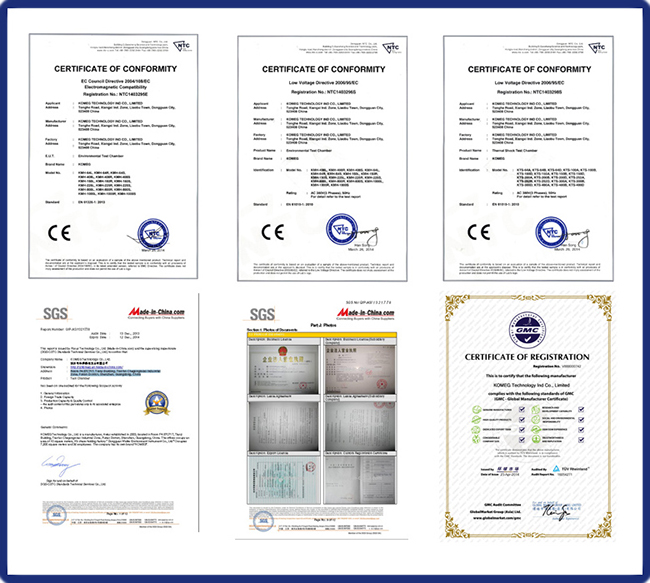

As a professional manufacturer and the best brand environmental test chamber in China, KOMEG specialized in Environmental testing equipment for quality conscious people since 1990. Our products are CE approved and we are the supplier for , UL, and world top 500 companies.

Some environmental test chamber details

Part of the certificate for KOMEG test chamber