Xi'an BBT Clay Technologies Co., Ltd. |

|

Verified Suppliers

|

|

Brick plant clay mixer machine double shaft mixer raw material dual shaft mixer mixing and homogenization

Clay brick plant double shaft mixer raw material mixing and homogenization

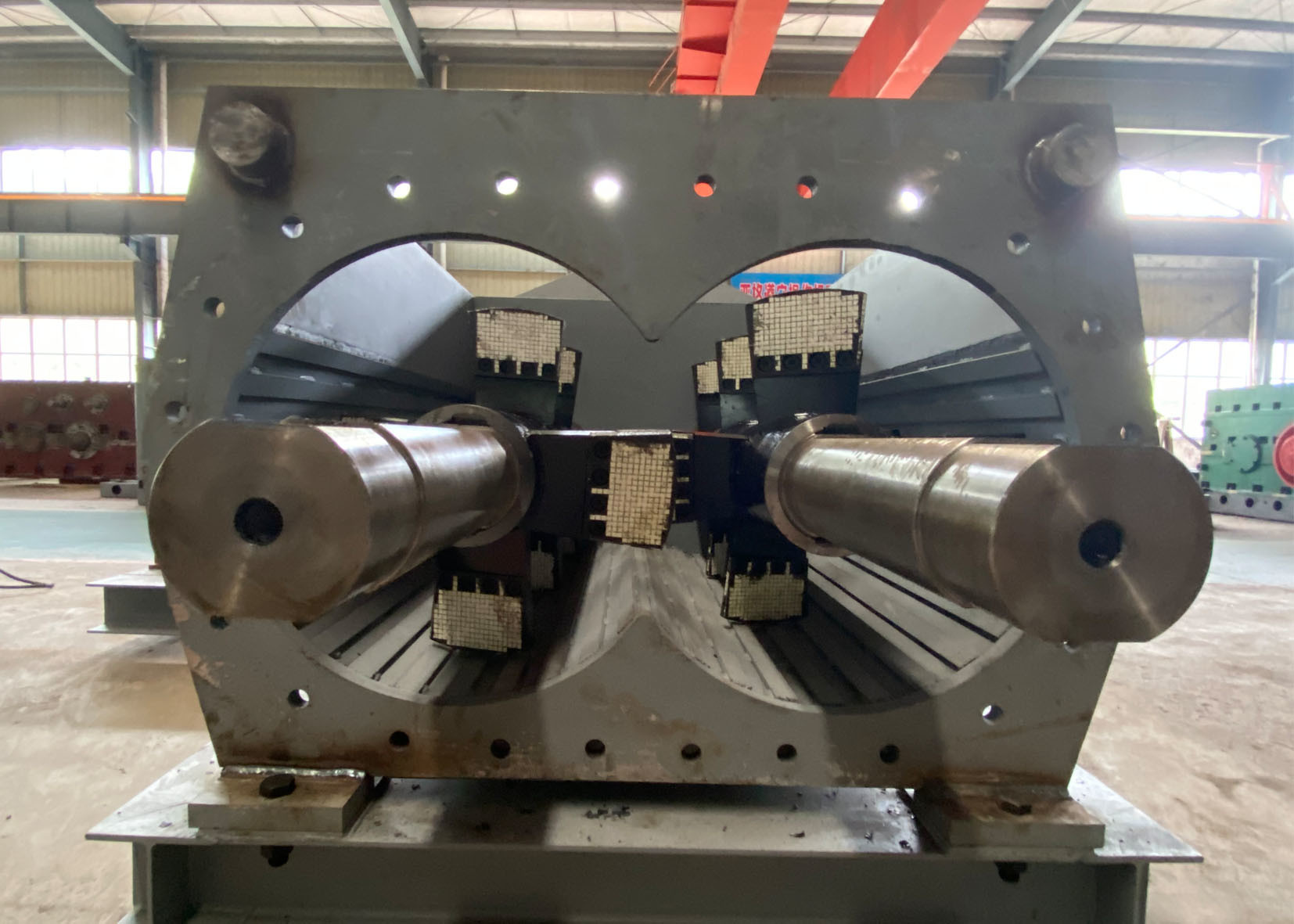

TWJH550 front grid mixer extruder is a new product developed by BBT company on the basis of absorbing the advanced experience of similar products abroad, and it occupies a leading position among similar products in China.

The function of the front grid mixer: homogenize and mix raw materials through biaxial stirring; Through reamer extrusion, strengthen the mutual penetration of water between raw materials and improve the plasticity of materials.

Working principle and structural characteristics:

The main part of this series of equipment is mainly composed of transmission motor, pneumatic clutch, hard tooth surface reducer, gear box, stirring tank, stirring shaft, stirring knife, sealing cylinder, extrusion reamer, compressor head, sieve plate, hydraulic station, base and other parts composition. There is a water adding pipeline on the stirring tank, which is used to adjust the molding moisture content of the raw materials. A pneumatic clutch is arranged between the motor and the reducer, which is used for overload protection of frequent start and stop of the equipment. The cutter head and sieve plate of the stirring blade are cast with wear-resistant alloy, and are connected with the fixed seat by high-strength bolts, which is convenient for maintenance and replacement. The extrusion reamer and the inner and outer conical sleeves are all made of wear-resistant alloy steel, which is wear-resistant and easy to replace.

Filter mixer of technical paramerters:

| Item | TWJH-550 | TWJH-750 |

| Diameter of auger | 550mm | 750mm |

| Rotate speed for main shaft | ≥30 rpm | ≥30rpm |

| Motor Power | 90+5.5 kw | 132-160kw |

| Diameter for screen hole | Customized building | Customized building |

| Production capacity | 45-50 m³/h | 60-75 m³/h |

| Total weight of equipment | 8900 kg | 15800 kg |

Filter mixer for clay brick making plant machinery

Filter mixer machine in auto brick production line Installation for auto brick making project