This document is the property of Xin Pei Enterprise and delivered on the express condition that it is not be

disclosed, reproduced or used, in whole or in part, for manufacture

or sale by anyone other than Xin Pei Enterprise. Without its prior consent, and that no right is granted to disclose

or to use any information in this document. |

1. Scope This specification covers the requirements for product performance

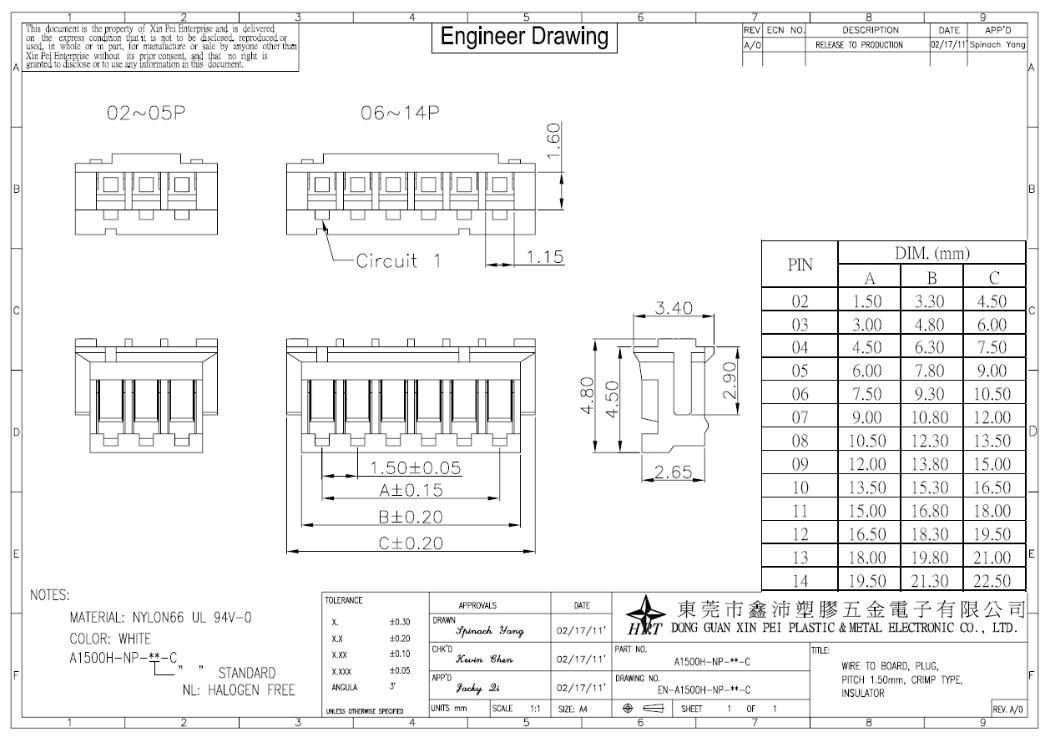

of 1.50mm pitch wire to board connectors series. 2. Construction,Dimensions,Material & Plating See the attached drawings 3. Ratings & Applicable Wires | Item | Standard | | Rated Voltage (Max.) | 100V AC/DC | Insulation O.D. 1.10mm (Max.) | | Rated Current (Max.) And Applicable Wires | AWG#26 | 1A AC/DC | | AWG#28 | 1A AC/DC | | AWG#30 | 1A AC/DC | | AWG#32 | 0.8A AC/DC | | Ambient Temperature Range | -25℃ ~ +85℃* |

*: Including terminal temperature rise 4. Electrical Performance | Test Description | Procedure | Requirement | | 4-1 | Contact Resistance | Mate connectors, measure by dry circuit, 20mV max., 10mA.(Based

upon JIS C5402 5.4) | 20mΩ (Max.) | | 4-2 | Insulation Resistance | Mate connectors, apply 500V DC between adjacent terminal or ground.

(Based upon JIS C5402 5.2/MIL-STD-202 Method 302 Cond. B) | 500MΩ (Min.) | | 4-3 | Dielectric Withstanding Voltage | Mate connectors, apply 500V AC (rms) for 1 minute between adjacent

terminal or ground. (Based upon JIS C5402 5.1/MIL-STD-202 Method

301) | No Breakdown. | | 4-4 | Contact Resistance on Crimped Portion | Crimp the applicable wire on to the terminal, measure by dry

circuit, 20mV (Max.)., 10mA. | 5mΩ (Max.) |

5. Mechanical Performance | Test Description | Procedure | Requirement | | 5-1 | Actuator Insertion & Withdrawal Force | Insert and withdraw connectors at the speed rate of 25±3mm /

minute. | Refer to paragraph 7 | | 5-2 | Crimping Pull Out Force | Fix the crimped terminal, apply axial pull out force on the wire at

the speed rat of 25±3mm / minute.(Based upon JIS C5402 6.8) | AWG#26 | 2.0kgf (Min) | | AWG#28 | 1.0kgf (Min) | | AWG#30 | 0.8kgf (Min) | | AWG#32 | 0.5kgf (Min) | | 5-3 | Terminal Insertion Force. | Insert the crimped terminal into the housing. | 1.00kgf (Max.) | | 5-4 | Terminal/Housing Retention Force. | Apply axial pull out force at the speed rate of 25±3mm / minute on

the terminal assembled in the housing. | 1.00kgf (Min.) | | 5-5 | Pin Retention Force | Apply axial push force at the speed rate of 25±3mm / minute | 0.70kgf (Min.) | | 5-6 | Durability | When mated up to 50 cycles repeatedly by the rate of 10 cycle per

minute. | Contact Resistance 40mΩ (Max.) | | 5-7 | Vibration | Amplitude: 1.5mm P-P Sweep time: 10-55-10 Hz in 1 minute Duration: 2 hours in each

X.Y.Z. axes. (Based upon MIL-STD-202 Method 201A) | Appearance No Damage. Contact Resistance 40mΩ (Max.) Discontinuity 1 μsec.(Max.) | | 5-8 | Physical Shock | 490m/s²{50G},3 strokes in each X.Y.Z. axes. (Based upon JIS

C0041/MIL-STD-202 Method 213B Cond. A) |

|

6. Environmental Performance And Others | Test Description | Procedure | Requirement | | 6-1 | Temperature Rise | Carrying rated current load.(Based upon UL 498) | 30℃(Max.) | | 6-2 | Heat Resistance | 85±2℃,96 hours (Based upon JIS C0021/MIL-STD-202 Method 108A Cond.

A) | Appearance No Damage. Contact Resistance 40mΩ (Max.) | | 6-3 | Cold Resistance | -25±3℃,96 hours (Based upon JIS C0020) | | 6-4 | Humidity | Temperature: 40±2℃ Relative Humidity : 90~95% Duration: 96 hours (Based upon JIS C0022/MIL-STD-202 Method 103B Cond. B) | Appearance No Damage. Contact Resistance 40mΩ (Max.) Insulation Resistance 50MΩ (Min.) Dielectric Withstanding Voltage Must meet 4-3 | | 6-5 | Temperature Cycling | 5 cycles of: a) -55℃ 30 minutes b) +85℃ 30 minutes (Based upon JIS C0025) | Appearance No Damage. Contact Resistance 40mΩ (Max.) | | 6-6 | Salt Spray | Tin-plated 12 hours / Gold- plated 24 hours exposure to a salt

spray from the 5±1% solution at 35±2℃. (Based upon JIS

C0023/MIL-STD-202 Method 101D Cond. B) | | 6-7 | SO2 Gas | 24 hours exposure to 50±5ppm. SO2 gas at 40±2℃. | | 6-8 | NH3 Gas | 40 minutes exposure to NH3 gas evaporating from 28% Ammonia

solution. |

| 6-9 | Solderability | Soldering Time: 5±0.5 sec. Solder Temperature: 245±5℃ | Solder Wetting 95% of immersed area must show no voids, pin holes | | 6-10 | Resistance to Soldering Heat (DIP) | Solder pot method Soldering time: 10±0.5 sec. Solder Temperature: 260±5℃ Solder iron method Soldering Time: 5±0.5 sec. Solder Temperature: 370℃ ~ 400℃ | Appearance No Damage. | | 6-11 | Resistance to Soldering Heat (SMT) | When reflowing Refer to paragraph 8 Solder iron method Soldering Time: 5±0.5 sec. Solder Temperature: 370℃ ~ 400℃ | Appearance No Damage. |

7. Actuator Insertion/Withdrawal Force [Unit : kgf] | Circuits | At Initial | | Insertion (Max.) | Withdrawal (Min.) | | Single | 0.70 | 0.06 | | 02 | 2.50 | 0.40 | | 03 | 3.00 | 0.50 | | 04 | 3.50 | 0.60 | | 05 | 4.00 | 0.70 | | 06 | 4.50 | 0.80 | | 07 | 5.00 | 0.80 | | 08 | 5.50 | 0.90 | | 09 | 6.00 | 0.90 | | 10 | 6.50 | 1.00 | | 11 | 7.00 | 1.00 | | 12 | 7.50 | 1.20 | | 13 | 8.00 | 1.20 |

|