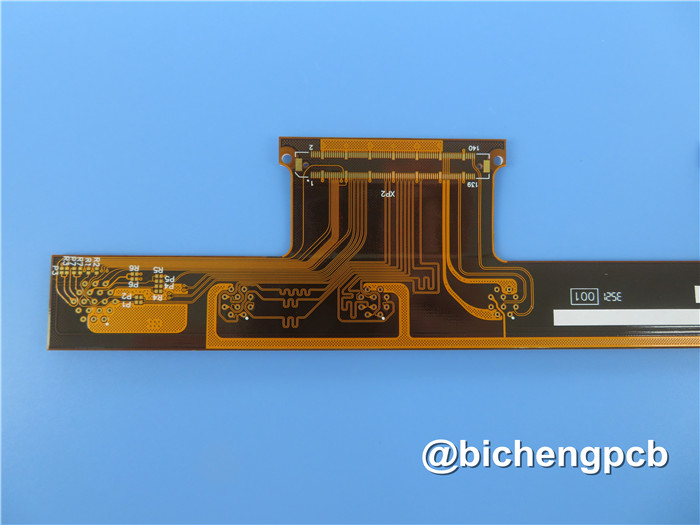

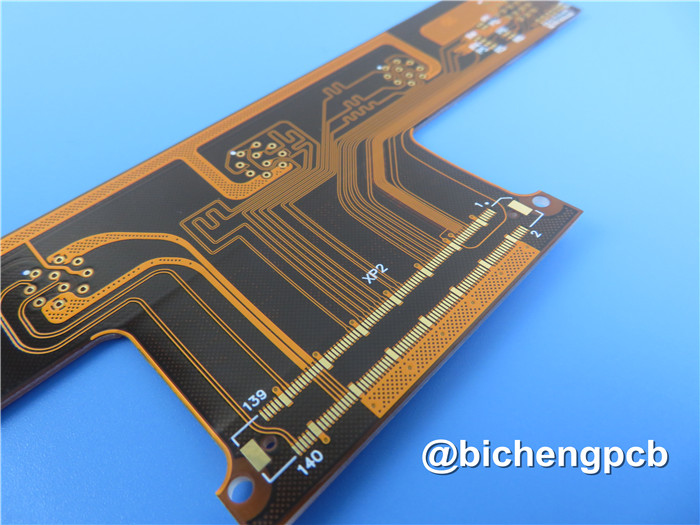

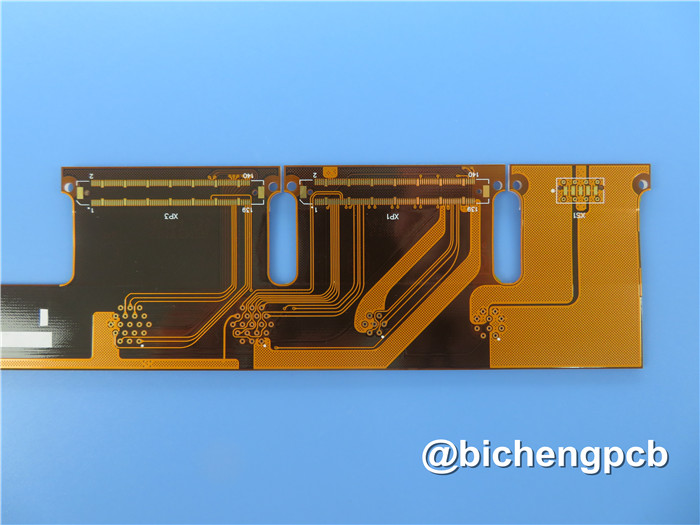

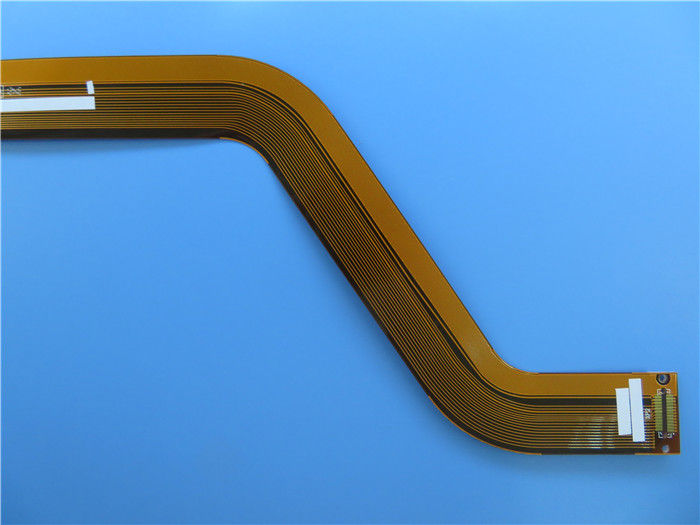

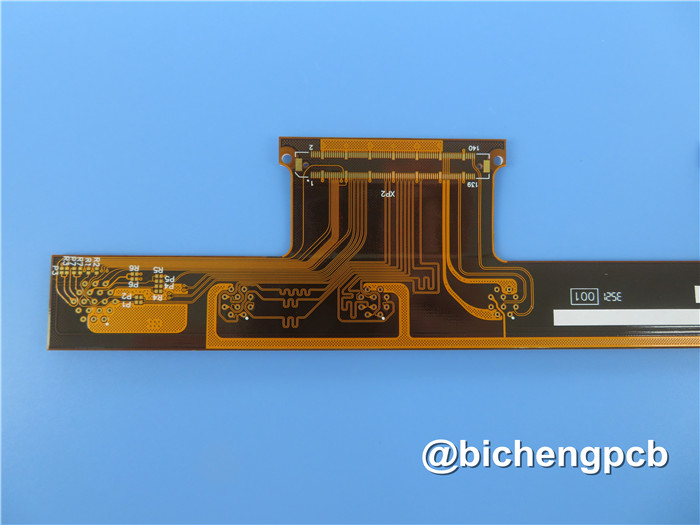

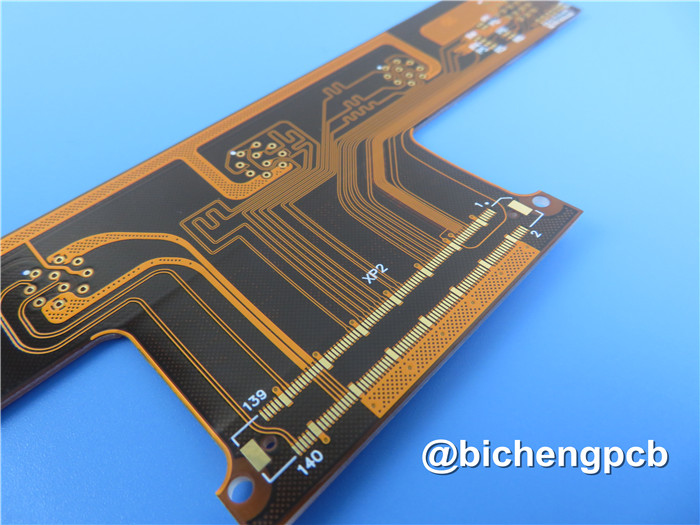

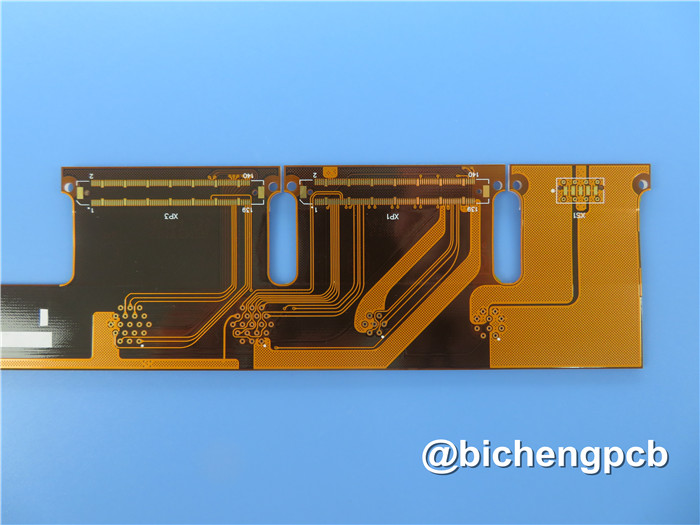

Flexible Printed Circuit FPC on Polyimide with 90ohm Impedance Controlled

(Flexible printed circuits are custom-made products, the picture

and parameters shown are just for reference)

General description

This is a type of flexible PCB built on polyimide 76 micron

substrate with 90 ohm impedance controlled on 0.15mm/0.3mm track

and gap for the application of USB Connector. It's standard 0.20 mm

thick with yellow solder mask (coverlay) on both sides and

immersion gold are on pads. FR-4 as stiffener is on the head and

tail. The base material is used from Shengyi, entire board

supplying 1 up flex per panel. They're fabricated per IPC 6012

Class 2 using supplied Gerber data. Each 25 pieces are packed for

shipment.

Parameter and data sheet

| PCB Size: | 196 X 35mm = 1 PCS |

| Number of Layers | 2 layers |

| Board Type | Flexbile PCB |

| Board Thickness | 0.2mm +/-10% |

| Stackup | TOP FR-4 Steffener 0.8mm |

| PI coverlay 0.025mm |

| Copper top 0.035mm finish |

| Polyimide substrate 0.076mm |

| Copper top 0.035mm finish |

| PI coverlay 0.025mm |

| Board Material Supplier | Shengyi |

| Tg Value of Board Material | 60℃ |

| |

| PTH Cu thickness | 20 um |

| Inner Iayer Cu thicknes | N/A |

| Surface Cu thickness | 35 um (1oz) |

| |

| Coverlay Colour | Yellow |

| Number of Coverlay | 2 |

| Thickness of Coverlay | 25 um |

| Stiffener | FR-4 0.8mm |

| |

| Type of Silkscreen Ink | N/A |

| Supplier of Silkscreen | N/A |

| Color of Silkscreen | N/A |

| Number of Silkscreen | N/A |

| |

| Minimum via (mm) | 0.3 |

| Minimum Trace (mil) | 5.90 |

| Minimum Gap(mil) | 11.8 |

| |

| Surface Finish | Immersion Gold |

| RoHS Required | Yes |

| Famability | 94-V0 |

| |

| Thermal Shock Test | Pass, -25℃±125℃, 1000 cycles. |

| Thermal Stress | Pass, 300±5℃,10 seconds, 3 cycles. No delamination, no blistering. |

| Function | 100% Pass electrical test |

| Workmanship | Compliance with IPC-A-600H & IPC-6013C Class 2 |

| Type of artwork to be supplied | email file, Gerber RS-274-X, PCBDOC etc |

| Service area | Worldwide, Globally. |

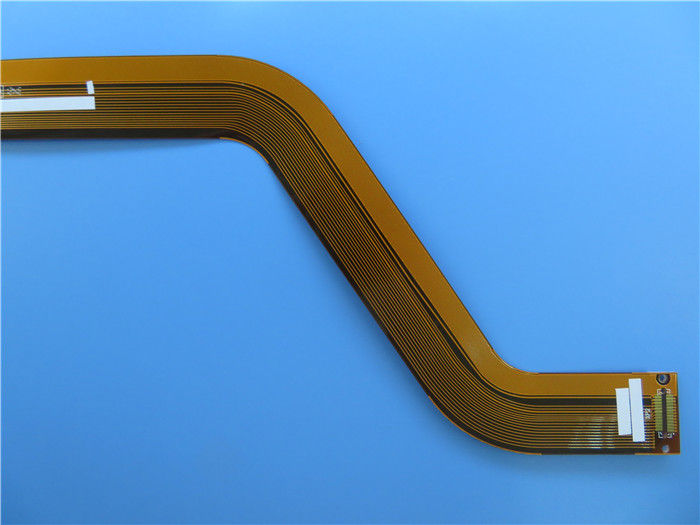

Features and benefits

Excellent flexibility;

Reducing the volume;

Weight reduction;

Consistency of assembly;

Increased reliability;

Powerful PCB capabilities support your research and development,

sales and marketing;

Delivery on time with higher than 98% on-time-delivery rate;

Team with passion, discipline, responsibility and honesty;

No minimum order quantity. 1 piece is available;

Applications

Flexible flat cable, Industrial control temperature controller soft

board, medical equipment controller, automobile GPS navigation flex

board, tablet keypad flex board, display backlight

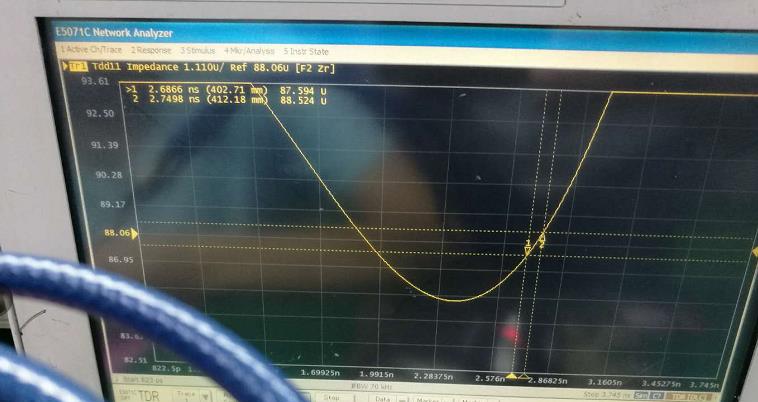

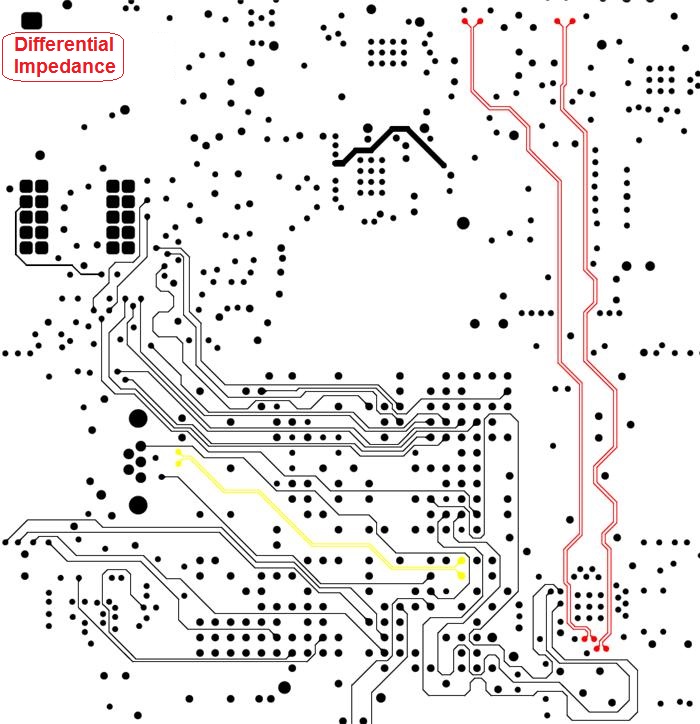

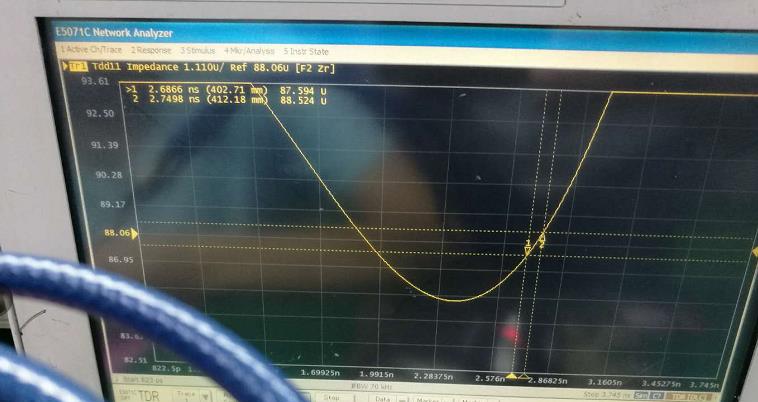

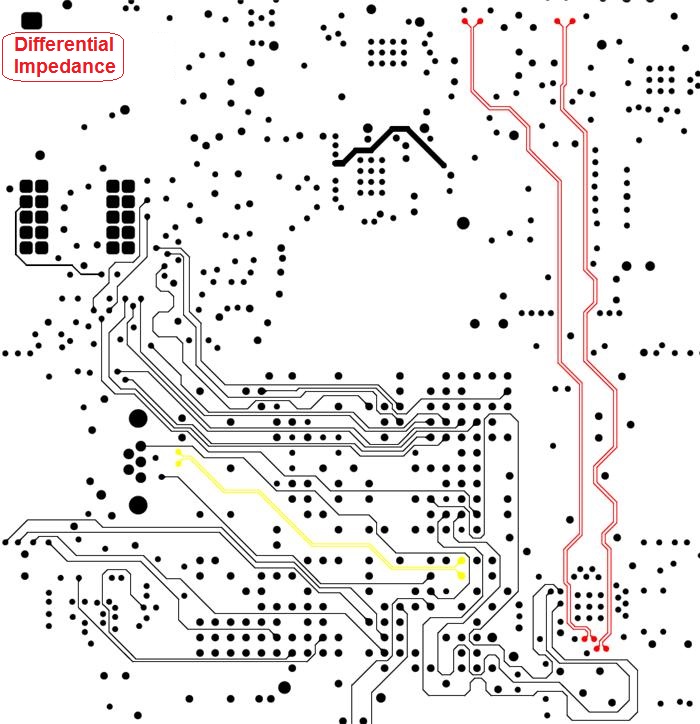

1.5 Single ended (line) impedance, Differential impedance

Definition of Characteristic Impedance

At a certain frequency, relative to a reference layer, the

resistance of its high-frequency signals or electromagnetic waves

in the process of transmission is called the characteristic

impedance, which is the vector summation of electrical impedance,

inductive reactance, capacitance resistance.

The classification of characteristic impedance

Common characteristic impedance is divided into: (1) Single ended

(line) impedance; (2) Differential impedance and (3) coplanar

impedance, etc.

Single ended impedance refers to the measured impedance of a single signal line. Differential impedance refers to the impedance measured between the two transmission

lines with equivalent width and spacing in differential drive. Coplanar impedance refers to the impedance measured when the signal line is

transmitting between its surrounding GND / VCC (the space between

the signal line to GND / VCC on both sides is equal).

The Determinant Condition Required for Impedance Control

When the signal is transmitted in the PCB conductor, if the length

of conductor is close to the 1/7 of the signal wavelength, then the

conductor at this time becomes a signal transmission line, the

other general signal transmission lines are required to be done

with impedance control. Whether it is required to control the

impedance in PCB production is based on the customer's requirement,

if the customer requires that a certain line width need to be done

with impedance control, it is required to control the impedance of

the line width in production.Three basic elements of impedance

match are the output impedance (the original active parts), the

characteristic impedance (signal line), the input impedance

(passive parts) (PCB board)

More Impedance Controlled Flexible Circuit (FPC)