Shenzhen Bicheng Electronics Technology Co., Ltd |

|

Flex/Rigid PCB Built on Polyimide and FR-4 With Immersion Gold or Immersion Silver or Immersion Tin for Video Cameras

(PCB's are custom-made products, the picture and parameters shown are just for reference)

Hello everyone.

Today, we're talking about rigid-flex PCB.

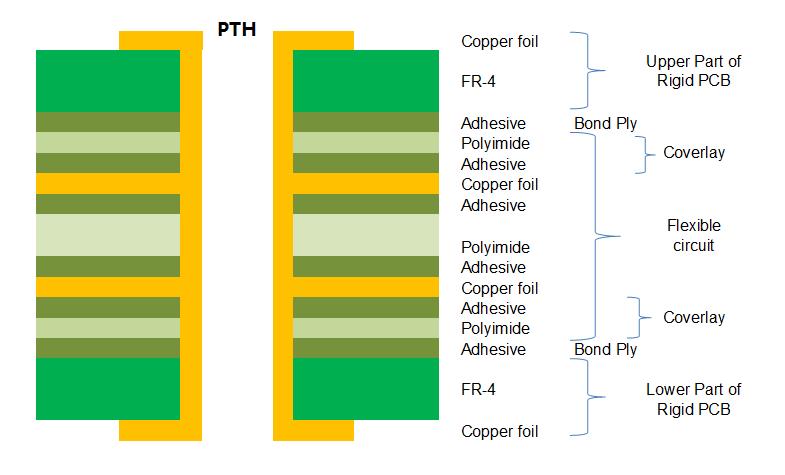

A rigid-flex PCB is a combination of rigid boards and flexible circuits, the latter creating flexible inter-connects between the rigid boards to which they are laminated by means of bond plies. Such as the following diagram is rigid-flex drawing.

Both ends are rigid board, flexible circuit is in the middle.

The flexible circuit is manufactured separately and bonded to the rigid boards, either symmetrically, i.e., in the middle of the rigid boards, or asymmetrically, i.e., to the outer side of the rigid boards to be interconnected.

Plated-through holes are provided in the rigid sections of the rigid-flex PCB to establish electrical connection between the flexible circuit and the electronic circuits of the rigid boards. The processes are similar to those used when manufacturing rigid multilayer boards.

Next coming up, let’s take a look at two PCB samples.

The first one is a 4-layer flex-rigid board. The flexible circuit is in the middle, and the two sides are rigid plate and symmetrical structure. The solder mask is green and the surface is treated with gold.

The second sample is a 6-layer flex-rigid board. The first layer and the second layer are the flexible board, located at the top of the flex-rigid board. The flexible board and the rigid board are connected by 1080 prepeg, and the third layer to the sixth layer is the rigid board. What we used is FR-4 from ITEQ Company: IT-180A. The inner layer is 0.5OZ, the outer layer is 1OZ, the whole finished plate thickness is 1.5mm, and the surface finish is immersion gold.

Our PCB Capability ( Rigid-flex PCB )

| PCB Material: | Polyimide and epoxy fibre glass |

| Designation: | PI+FR4 |

| Layer count: | 4 Layer, multilayer |

| Copper weight: | 0.5oz (17 µm), 1oz (35µm), 2oz (70µm) |

| PCB thickness: | 0.5mm, 0.8mm, 1.0mm, 1.2mm, 1.6mm |

| 1.8mm, 2.0mm | |

| PCB size: | ≤400mm X 500mm |

| Solder mask: | Green, Black, Blue, Yellow, Red etc. |

| Surface finish: | ENIG, Immersion tin, OSP,etc.. |

The main raw materials are polyimide and FR-4, copper thickness ranges 0.5oz to 2oz, PCB thickness is up to 2.0mm and maximum size within 400X 500mm.

Flex-rigid PCB contains both flexible area and rigid area, which is of great help to save the internal space of the product, to reduce the volume of the finished product and improve the performance of the product.

Should you have any questions, please contact us.

Thank you for reading.

Appendix: Our FPC Capability 2021

| No. | Specifications | Capabilities |

| 1 | Board Type | Single layer, Doulbe layer, Multilayer, Rigid-Flex |

| 2 | Base Material | PI, PET |

| 3 | Copper Weight | 0.5oz, 1oz, 2oz |

| 4 | LED Maximum Size | 250 x 5000mm |

| 5 | General Maximum Size | 250 x 2000mm |

| 6 | Board Thickness | 0.03mm-3.0mm |

| 7 | Thickness Tolerance | ±0.03mm |

| 8 | Mininum Drill Hole | 0.05mm |

| 9 | Maximum Drill Hole | 6.5mm |

| 10 | Tolerance of Drill Hole | ±0.025mm |

| 11 | Thickness of Hole Wall | ≧ 8 um |

| 12 | Minimum Track/Gap of Single Layer Board | 0.025/0.03mm |

| 13 | Minimum Track/Gap of Double Layer and Multilayer Board | 0.03/0.040mm |

| 14 | Etching Tolerance | ±0.02mm |

| 15 | Minimum Width of Silk Legend | ≧ 0.125mm |

| 16 | Minimum Heigh of Silk Legend | ≧0.75mm |

| 17 | Distance from Legend to Pad | ≧0.15mm |

| 18 | Distance from Opening Solder Mask of Drill Coverlay to Track | ≧0.03mm |

| 19 | Distance from Opening Solder Mask of Punching Coverlay to Track | ≧0.03mm |

| 20 | Thickness of Immersion Nickel | 100-300u" |

| 21 | Thickness of Immersion Gold | 1-3u" |

| 22 | Thicnkess of Immersion Tin | 150-400u" |

| 23 | Minimum Electrical Testing Pad | 0.2mm |

| 24 | Minimum Tolerance of Outline(Normal Steel Mould Punch) | ±0.1mm |

| 25 | Minimum Tolerance of Outline (Precision Steel Mould Punch) | ±0.05mm |

| 26 | Mininum Radius of Bevel Angle (Outline) | 0.2mm |

| 27 | Stiffner Material | PI, FR-4, 3M Adhesive, PET, Steel Sheet |

| 28 | RoHs | Yes |

| 29 | Solder Mask Colour | Yellow, White, Black, Green |