Eternal Bliss Alloy Casting & Forging Co., Ltd. |

|

![]()

Wear Plates for Shot Blast Machines, Chutes, Clinker Silo,Port

Machinery and Ball Mills

This specification covers a group of white cast irons that have

been alloyed to secure high resistance to abrasive wear in the

applications of the mining, milling, earth-handling, and

manufacturing industries. These alloys are made by melting process

and shall have microstructures that consist of carbides,

martensite, bainite, austenite, and in exceptional cases, minor

amounts of graphite or pearlite. The following conditions for

casting will be supplied: as-cast, as-cast and stress relieved,

hardened, hardened and stress relieved, or softened for machining.

Heat treatment shall be done. The chemical composition of a class

and type (that is, Class I, Type A) shall conform to the range of

values specified for carbon, manganese, silicon, nickel, chromium,

molybdenum, copper, phosphorus, and sulfur. Hardness test shall

also be made.

Plate Thickness :

10mm, 12mm, 14mm, 15mm, 16mm, 18mm, 20mm, 15mm, 30mm, 32mm, 40mm, 50mm, 60mm, 80mm, 100mm, 200mm, 500mm, 1000mm.

Section Thickness:

1inch, 2″, 3″, 4″, 5″, 8″, 10″, 20″, 30″, 40″.

| Mill Size | Ball Charge (t) | Mill Size | Ball Charge (t) | Mill Size | Ball Charge (t) |

| Ф900×1800 | 1.5 | Ф2400×1000 | 50 | Ф3800×1300 | 185 |

| Ф900×3000 | 2.7 | Ф2400×1100 | 60-62 | ||

| Ф1200×2400 | 3 | Ф2400×1200 | 63-65 | Ф3800×1300 | 185 |

| Ф1200×3000 | 3.5 | Ф2400×1200 | 66-68 | ||

| Ф1200×4500 | 5 | Ф2600×1000 | 64 | Ф4000×5000 | 121 |

| Ф1500×3000 | 7.5 | Ф2600×1100 | 69 | Ф4000×6000 | 146 |

| Ф1500×4500 | 11 | Ф2600×1300 | 80 | Ф4000×6700 | 149 |

| Ф1500×5700 | 12 | Ф2700×4000 | 40 | Ф4000×1300 | 191 |

| Ф1830×3000 | 11 | Ф2700×4500 | 48 | Ф4200×1100 | 190 |

| Ф1830×4500 | 15 | Ф3000×900 | 80-83 | ||

| Ф1830×6400 | 21 | Ф3000×1100 | 95-100 | Ф4200×1300 | 225 |

| Ф1830×7000 | 23 | Ф3000×1200 | 103 | ||

| Ф2100×3000 | 15 | Ф3000×1300 | 110-116 | Ф4200×1300 | 225 |

| Ф2100×4500 | 24 | Ф3200×4500 | 65 | ||

| Ф2100×7000 | 26 | Ф3200×1100 | 110-112 | Ф4200×1300 | 225 |

| Ф2200×4500 | 27 | Ф3200×1300 | 125 | ||

| Ф2200×6500 | 35 | Ф3400×1100 | 115 | Ф4500×6400 | 172 |

| Ф2200×7000 | 35 | Ф3500×1300 | 150 | Ф4600×1350 | 280 |

| Ф2200×7500 | 35 | ||||

| Ф2200×1100 | 50 | Ф3500×1300 | 150 | Ф4600×1400 | 285 |

| Ф2400×3000 | 23 | Ф5000×1500 | 350 | ||

| Ф2400×4500 | 30 | Ф3600×4500 | 90 | Ф5030×6400 | 216 |

| Ф2400×800 | 39.5-42 | Ф3600×6000 | 110 | Ф5030×8300 | 266 |

| Ф2400×900 | 50 | Ф3600×8500 | 131 | Ф5500×8500 | 338 |

Material Grade:

1.Martensitic Cr Mo AlloySteel(ZG50Cr5Mo,ZG60Cr6Mo,Cr12Mo): Hardness:≥HRC48, Impact value:≥25J.

2.High Cr white iron(BTMCr15Mo,BTMCr20Mo,BTMCr26Mo):Hardness:≥HRC56,

Impact value:≥5J.

3.Ni-hard White Iron: AS2027 NiCr2-500,AS2027 NiCr1-550,AS2027

NiCr4-500,AS2027 NiCr4-600,AS2027 NiCr4-630AS2027 NiCr2-500,AS2027

NiCr1-550,AS2027 NiCr4-500,AS2027 NiCr4-600,AS2027 NiCr4-630

Material Grades & Alloys for Wear Plates & Chute Liners:

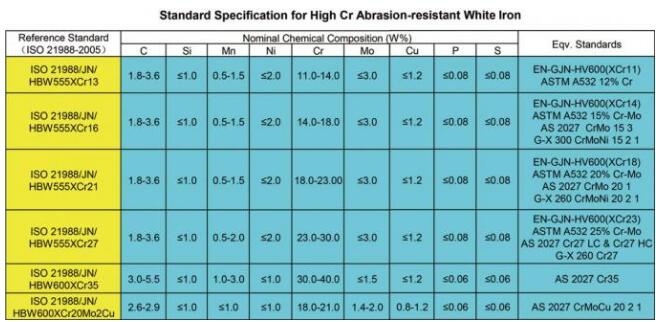

1. High Cr white iron :

| ISO 21988/JN/ | HBW | C | Si | Mn | P | s | Cr | Ni | Mo | Cu |

| HBW555XCr13 | 555 | 1.8-3.6 | 1.0 | 0.5-1.5 | 0.08 | 0.08 | 11-14 | 2.0 | 3.0 | 1.2 |

| HBW555XCr16 | 555 | 1.8-3.6 | 1.0 | 0.5-1.5 | 0.08 | 0.08 | 14-18 | 2.0 | 3.0 | 1.2 |

| HBW555XCr21 | 555 | 1.8-3.6 | 1.0 | 0.5-1.5 | 0.08 | 0.08 | 18-23 | 2.0 | 3.0 | 1.2 |

| HBW555XCr27 | 555 | 1.8-3.6 | 1.0 | 0.5-1.5 | 0.08 | 0.08 | 23-30 | 2.0 | 3.0 | 1.2 |

| HBW600XCr35 | 600 | 3.0-5.5 | 1.0 | 1.0-3.0 | 0.06 | 0.06 | 30-40 | 1.0 | 1.5 | 1.2 |

| HBW600XCr20Mo2Cu | 600 | 3.0-5.5 | 1.0 | 1.0 | 0.06 | 0.06 | 18-21 | 1.0 | 1.4-2.0 | 0.8-1.2 |

2. Nihard white Iron:

Handelsname Kurzzeichen W.St.Nr.

Ni-hard 1: ≥ HB500 G-X 330 NiCr 4 2 0.9625

Ni-hard 2: ≥ HB550 G-X 3260 NiCr 4 2 0.9620

Ni-hard 4: ≥ HB600, HB630 G-X 300 NiCrSi 9 5 2 0.9630

G-X 300 NiMo 15 3 0.9635

G-X 260 Cr 27 0.9635

| ISO 21988/JN/ | HBW | C | Si | Mn | P | S | Ni | Cr |

| HBW480Cr2 | 480 | 2.5-3.0 | 0.8 | 0.8 | 0.10 | 0.10 | 3.0-5.5 | 1.5-3.0 |

| HBW500Cr9 | 500 | 2.4-2.8 | 1.5-2.2 | 0.2-0.8 | 0.06 | 0.06 | 4.0-5.5 | 8.0-10.0 |

| HBW510Cr2 | 510 | 30.-3.6 | 0.8 | 0.8 | 0.10 | 0.10 | 3.0-5.5 | 1.5-3.0 |

| HBW555Cr9 | 555 | 2.5-3.5 | 1.5-2.5 | 0.3-0.8 | 0.08 | 0.08 | 4.5-6.5 | 8.0-10.0 |

| HBW630Cr9 | 630 | 3.2-3.6 | 1.5-2.2 | 0.2-0.8 | 0.06 | 0.06 | 4.0-5.5 | 8.0-10.0 |

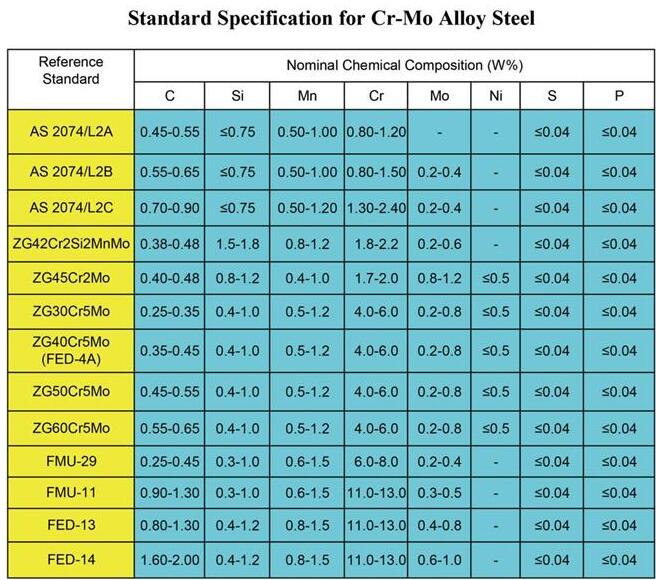

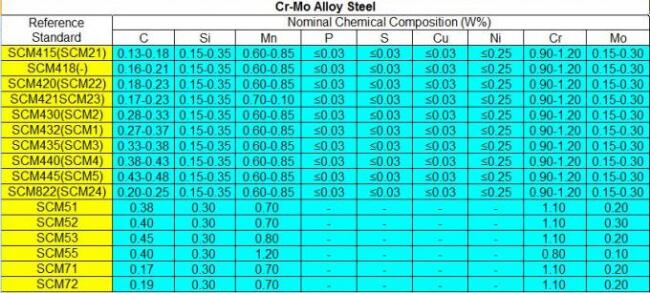

3. Martensitic Cr- Mo Alloy Steel: Hardness: ≥HRC48

4. Pearlitic Cr-Mo Alloy Steel Hardness: HB310-375

5. Heat-resistant Steel Plates.

6. High-temperature Alloy Plates.

7. Hardox Plates:

HARDOX400,HARDOX450, HARDOX500, HARDOX550, HARDOX600,HARDOX630.

8. Bisplate:

BISPLATE 100, BISPLATE 360, BISPLATE 400, BISPLATE 450, BISPLATE 500, BISPLATE 600

Quality Level: As per National Standard & International Standards.

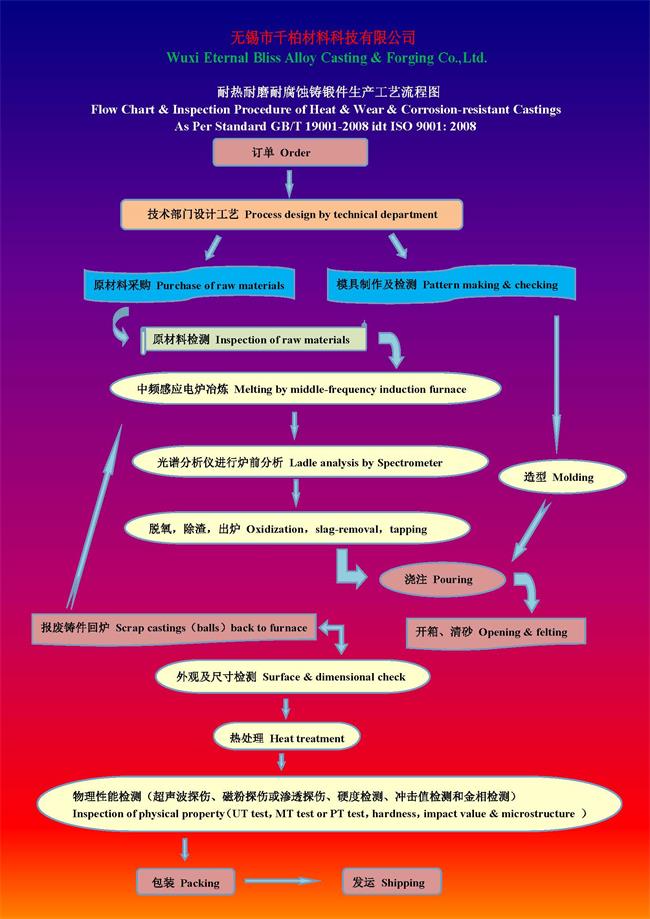

Production Process: Sand ProcessWith proper heat-treatment(quenching and tempering) process to achieve ideal hardness and impact value .

Shape:

Flat Plate, Arc Plate, Waved Plates, Corrugated Plates

Bolted Plates: one-hole, two-holes, three holes, four holes, oval - hole.

Application:

1.Armed plates for clincker silo in cement plants.

2.Wear plates for chutes, material bunkers for port machinery.

3.Material hoppers in steel mills.

4.High abrasion plates for material bin for port maachinery.

5.Wear plates for coal hoppers.

Special Features:

1. We make Cr-Mo Alloy steel and high Cr white iron castings with Sodium Silicate Sand Process and Resin Sand Process.

2. We supply finished alloy steel castings with heat-treatment and machining process.

3. We can produce Alloy Cr-Mo Steel and White Iron castings as per GB/T26651,GB/T 8263-1999,AS2074,AS2027,DIN 1695, AISI,ASTM,JIS G 5153,NF A32401,BS4844.

4. We can recommend suitable material grades of wear parts for you as per your specific working condition.

5. Design of wear plates & Chute Liners.

Width and length of wear plates determines hole pattern, regardless of thickness.

6. Material Selection of Wear Plates & Chute Liners.

![]()

1. 18-year Foundry Operation Experience.

2. Friendly & High Efficient Technical & Commercial Communication.

3. Professional Export Practices: Have Exported to +60 Overseas Countries.

Our Trade Show

Our booth No. 14-A29-5 in Newcast 2015,Germany

Hall 14, Stand No.A29-5.

Contact Us for further information about products & service:

Mr.John Liu

Project Manager

Tel: 0086-188 0059 6372

Fax: 0086-510-6879 2172

E-mail: cast@ebcastings.com; ebcastings@163.com

Skype ID:julia.zhu26

QQ: 217 039 6403

www.ebcastings.com

Eternal Bliss Alloy Casting & Forging Co.,LTD.

Add.: J-Sci-Tech Park, Binhu District,Wuxi,214122, Jiangsu,China