ZhengZhou HengXing Heavy Equipment Co.,Ltd. |

|

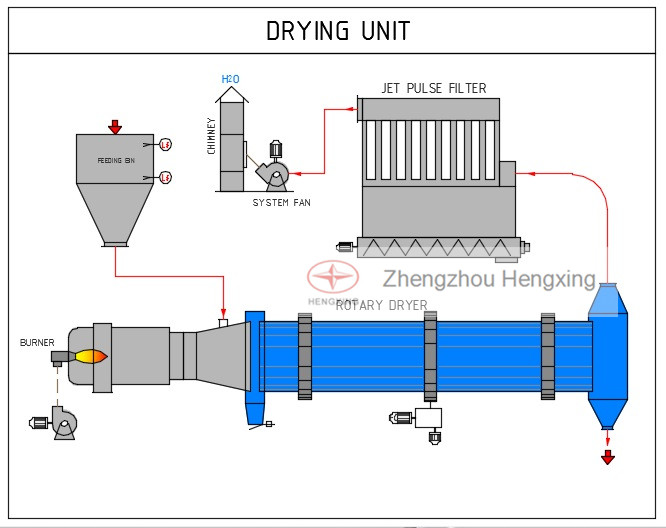

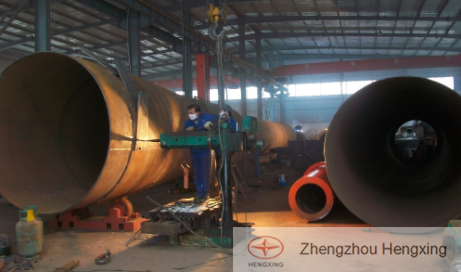

Chemical analysis was carried out on the material inspection, according to the requirements of GB700-2006, dryer drum thickness < = 20 mm we use Q235 - A, > 20 mm we use Q235 - B; According to the GB/T 2970-2004 class ii, the range of 60 mm weld edge every board before cutting for ultrasonic flaw detection.

the dryer cylinder section for toroidal welding, longitudinal along the entire circumference of not more than two weld article number, and shell welds shall be full, the minimum is not lower than the parent metal surface, the top should not be higher than 3 mm, feed plate weld should be smooth.Weld edge bite depth should not be greater than 0.5 mm, continuous length should not be greater than 100 mm, should not exceed the total length of each weld bite edge which 10% of the weld length

Examination all the parts according to the drawing after processing completion. Spraying primer, rust preventing paint, and heat resistance paint.

Model (mm) | Inclination (%) | rotation speed (r/min) | input temperature | motor power (kw) | output(t/h) | weight(t) |

Φ1000×10000 | 3-5 | 3-8 | ≤700 | 5.5 | 1.0-3.5 | 5.6 |

Φ1200×10000 | 3-5 | 3-8 | ≤700 | 7.5 | 1.8-5 | 14.5 |

Φ1200×12000 | 3-5 | 3-8 | ≤700 | 11 | 2-6 | 14.8 |

Φ1500×12000 | 3-5 | 2-6 | ≤800 | 15 | 3.5-9 | 17.8 |

Φ1800×12000 | 3-5 | 2-6 | ≤800 | 18 | 5-12 | 25 |

Φ2200×12000 | 3-5 | 1.5-6 | ≤800 | 18.5 | 6-15 | 33 |

Φ2200×18000 | 3-5 | 1.5-6 | ≤800 | 22 | 10-18 | 53.8 |

Φ2200×20000 | 3-5 | 1.5-6 | ≤800 | 30 | 12-20 | 56 |

Φ2400×20000 | 3-5 | 1.5-5 | ≤800 | 37 | 18-30 | 60 |

Φ2800×15000 | 3-5 | 1.5-5 | ≤800 |

|

Rotary dryer successful installation site in China and abroad:

Package and shippping :

What about Warranty of the products?

Hengxing equipment grants our customers a twelve-month-period

warranty from the date of delivery for machines exported from us.

During the warranty period, in case any defect of material or

workmanship occurred with spare parts in normal operation, we will

at our discretion replace or repair the defective parts freely.

Q: The reason you choose Hengxing equipment

1. Professional manufacturer of supplying mining crushing

equipment, construction equipment, Ore beneficiation equipment and

mining dryers.

2. Experienced and professional R&D team and manufacturing

team;

3. Professional sales team consisted of dedicated, dynamic and

innovative people with international version.

4. Professional logistics service ensuring safety and timely

delivery of products all over the world through ocean, airline,

road and railway.