Shijiazhuang Zhongtai Pipe Technology Development Co., Ltd |

|

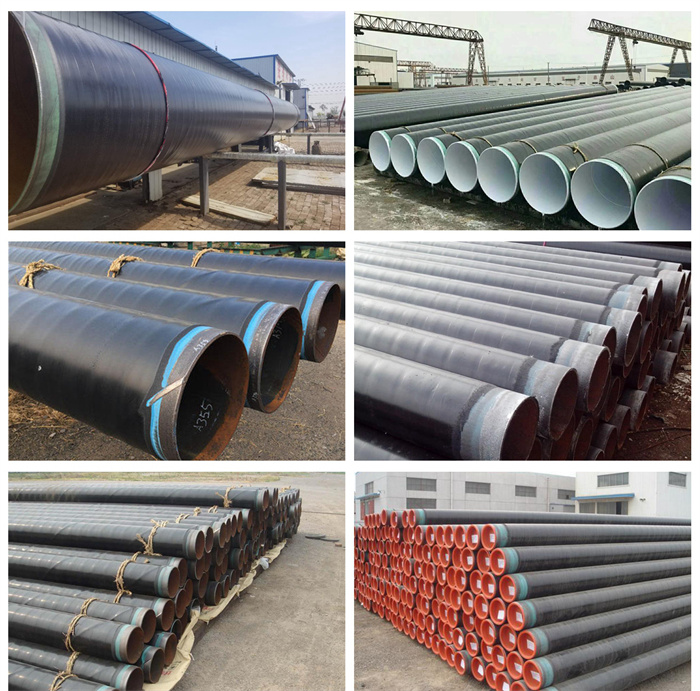

Tube Conveyor Line Petroleum And Gas Oil Casing High-Grade Steel Pipe API 5L Standard Tube Mill

Product Introduction

High-frequency welded pipe machinery is the production of low carbon low alloy steel material welded pipe special equipment, the specifications of the steel belt feeding machine will do the trick, by forming roller steel with curled up into a tube, then using high-frequency proximity effect and skin effect for tube side heat quickly to welding temperature, and under the squeezing roller extrusion complete welding, then through cooling, Sizing and roughing to the required size of steel pipe. The company's roll forming unit, FFX forming unit, roll row forming unit can produce X80, J55 API oil casing, oil and gas pipe, in line with API-5L, API-5CT and other

What is ZTF?

ZTF is a forming technique developed by ZTZG in 2005. It allows the shared-usage of rollers during break-down section when forming pipe, saving significant mould and labor cost while greatly improving production efficiency. It earns the reward of ‘Technology Innovation Award’ by ‘China Cold Forming Steel Association’ in 2010. After absorbing advanced pipe making technology from both abroad and domestic, our innovative designed production line and each single unit of the production line are not only economical but also practical.

ZTF advantages:

(1) Save 60% roller cost per specification of desired product.

(2) Eliminate production down time for break-down forming section roller replacement (typically 1-2 days per roller replacement).

(3) Electric controlled with high automation level.

Higher precision and faster roller change speed.

Product Parameter | ||

Product&yield | Round Pipe | 8mm-720mm Thickness:0.8mm-22mm |

Square & rectangle tube | 10mm×10mm -600mm×600mm Thickness:0.8mm-22mm | |

Length | 6m-12m Length Tolerance: ±3mm | |

Production Speed | 20-120 m/min | |

Production capacity | 30,000ton/year | |

Consumption | Mill installed capacity | 220 kw |

Line Area | 185m(length) ×27m (width) | |

worker | 6-18 workers | |

Raw Material | Carbon Steel coil | Carbon steel coil Q235B(ASTM GR·D,σs 230) |

Width | 25mm-2200mm Thickness: 0.8mm-22.0mm | |

Coil ID | 580-700mm | |

Coil OD | Max 1800mm | |

Coil Weight | 6.0t | |

FAQ

Q: Are you a manufacturer?

A: Yes, we are a manufacturer. We have 4 factories ( Machining,

Assembling, Heat treatment, and Moulding ). We also have our own

R&D department. Welcome to visit us.

Q: What kind of payment term do you do?

A: We do T/T.

Q: What info do you need before giving me the price and proposal?

A: Since we design individual machines based on our customer's

requirements, we need your desired products' basic dimensions,

including all the pipe diameter(or tube length), thickness range,

usage, raw material steel grade, coil weight, and degree of

automation.

Q: What should I do if I just start a new business?

A: Contact us immediately, we provide a free consultant for

pre-sales service. Also, we can help you solve the raw material

(steel coil) purchase, worker training, international market price,

and more.

Q: How do you do QA?

A: We have a special team to do strict QA, this is one of our

strengths:

(1)Every gearbox will be tested for 8 hours with oil inside to

guarantee there is no leak.

| Model List | ||||

| Model | Round pipe mm | Square pipe mm | Thickness mm | Working spead m/min |

| ERW20 | Ф8-Ф20 | 6x6-15x15 | 0.3-1.5 | 120 |

| ERW32 | Ф10-Ф32 | 10x10-25x25 | 0.5-2.0 | 120 |

| ERW50 | Ф20-Ф50 | 15x15-40x40 | 0.8-3.0 | 120 |

| ERW76 | Ф32-Ф76 | 25x25-60x60 | 1.2-4.0 | 120 |

| ERW89 | Ф42-Ф89 | 35x35-70x70 | 1.5-4.5 | 110 |

| ERW114 | Ф48-Ф114 | 40x40-90x90 | 1.5-4.5 | 65 |

| ERW140 | Ф60-Ф140 | 50x50-110x110 | 2.0-5.0 | 60 |

| ERW165 | Ф76-Ф165 | 60x60-130x130 | 2.0-6.0 | 50 |

| ERW219 | Ф89-Ф219 | 70x70-170x170 | 2.0-8.0 | 50 |

| ERW273 | Ф114-Ф273 | 90x90-210x210 | 3.0-10.0 | 45 |

| ERW325 | Ф140-Ф325 | 110x110-250x250 | 4.0-12.7 | 40 |

| ERW377 | Ф165-Ф377 | 130x130-280x280 | 4.0-14.0 | 35 |

| ERW406 | Ф219-Ф406 | 170x170-330x330 | 6.0-16.0 | 30 |

| ERW508 | Ф273-Ф508 | 210x210-400x400 | 6.0-18.0 | 25 |

| ERW660 | Ф325-Ф660 | 250x250-500x500 | 6.0-20.0 | 20 |

| ERW720 | Ф355-Ф720 | 300x300-600x600 | 6.0-22.0 | 20 |