Shijiazhuang Zhongtai Pipe Technology Development Co., Ltd |

|

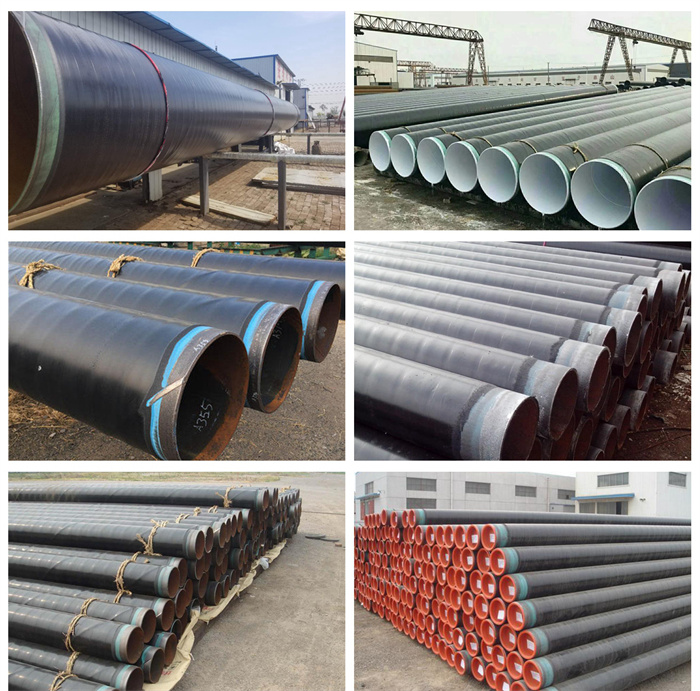

Natural Gas Delivery Pipes Casing High Grade Steel Pipe API 5L Standard Tube Mill

Product Introduction

High-frequency welded pipe machinery is the production of low carbon low alloy steel material welded pipe special equipment, the specifications of the steel belt feeding machine will do the trick, by forming roller steel with curled up into a tube, then using high-frequency proximity effect and skin effect for tube side heat quickly to welding temperature, and under the squeezing roller extrusion complete welding, then through cooling, Sizing and roughing to the required size of steel pipe. The company's roll forming unit, FFX forming unit, roll row forming unit can produce X80, J55 API oil casing, oil, and gas pipe, in line with API-5L, API-5CT, and other standards.

API Pipeline Process

Loading coil - Uncoil - Straighten head - Ultrasonic plate testing

- Shearing and butt welding - Spiral loop - Edge planing - Forming

- High-frequency welding - Remove inside and outside the burr -

Ultrasonic weld seam inspection - Polishing - Intermediate

frequency annealing - Air cooling and water cooling - Correct

reverse - Sizing finishing - Turkey head straightening - Length cut

- Sampling test - Straightening - Tube end facing - Hydraulic test

- ultrasonic flaw detection - Coating - Marking - Packaging -

Warehousing

Machine Parameters

| Product&yield | Round Pipe | 60mm-720mm Thickness:1.5.0mm-22.0mm |

| Length | 6m-12m Length Tolerance: ±3mm | |

| Production Speed | 20-50 m/min | |

| Production capacity | 30,000ton/year | |

| Consumption | Mill installed capacity | 220 kW |

| Line Area | 85m(length) ×7m (width) | |

| worker | 6-8 workers | |

| Raw Material | Carbon Steel coil | Q235A, Q23b, 0Cr13, 1Cr17, 00Cr19Ni11, 1Cr18Ni9, 0Cr18Ni11Nb. Q345 L245 L290 X42 X46 X70 X80 |

| Width | 240mm-2200mm Thickness: 1.5mm-22.0mm | |

| Coil ID | 580-700mm | |

| Coil OD | Max 1800mm | |

| Coil Weight | 25.0t |

Application

Annual output of 200,000 tons of N80, P110 steel grade oil special pipe production capacity. As an important equipment for oil and gas drilling and transportation, the special oil pipe is widely used in the connection between drill collar and bit, drilling power transmission, borehole wall support, oil and gas transportation, etc. In recent years, with the continuous increase of oil and gas exploration and development in China, the demand for special oil pipes for medium and high grade and special technical requirements continues to grow.

FAQ

Q: Are you a manufacturer?

A: Yes, we are a manufacturer. We have 4 factories ( Machining,

Assembling, Heat treatment, and Moulding ). We also have our own

R&D department. Welcome to visit us.

Q: What kind of payment term do you do?

A: We do T/T.

Q: What info do you need before giving me the price and proposal?

A: Since we design individual machines based on our customer's

requirements, we need your desired products' basic dimensions,

including all the pipe diameter(or tube length), thickness range,

usage, raw material steel grade, coil weight, and degree of

automation.

Q: What should I do if I just start a new business?

A: Contact us immediately, we provide a free consultant for

pre-sales service. Also, we can help you solve the raw material

(steel coil) purchase, worker training, international market price,

and more.

Q: How do you do QA?

A: We have a special team to do strict QA, this is one of our

strengths:

(1)Every gearbox will be tested for 8 hours with oil inside to

guarantee there is no leak.

| Model List | ||||

| Model | Round pipe mm | Square pipe mm | Thickness mm | Working spead m/min |

| ERW140 | Ф60-Ф140 | 50x50-110x110 | 2.0-5.0 | 60 |

| ERW165 | Ф76-Ф165 | 60x60-130x130 | 2.0-6.0 | 50 |

| ERW219 | Ф89-Ф219 | 70x70-170x170 | 2.0-8.0 | 50 |

| ERW273 | Ф114-Ф273 | 90x90-210x210 | 3.0-10.0 | 45 |

| ERW325 | Ф140-Ф325 | 110x110-250x250 | 4.0-12.7 | 40 |

| ERW377 | Ф165-Ф377 | 130x130-280x280 | 4.0-14.0 | 35 |

| ERW406 | Ф219-Ф406 | 170x170-330x330 | 6.0-16.0 | 30 |

| ERW508 | Ф273-Ф508 | 210x210-400x400 | 6.0-18.0 | 25 |

| ERW660 | Ф325-Ф660 | 250x250-500x500 | 6.0-20.0 | 20 |

| ERW720 | Ф355-Ф720 | 300x300-600x600 | 6.0-22.0 | 20 |