Rotary evaporator’s working principle is to rotate the glass flask

which filled with materials under constant temperature heating, and

the system connect to the negative pressure to low the boiling

point, then liquid forms a film and evaporates,at last it recovers

the menstruum by the glass coil condenser and receiving flask. It

is specially applicable for the concentration, crystallization,

separation and menstruum recovery of heat sensitive materials.

Adopt advanced frequency conversion and electronic speed regulation

to ensure the stable working of motor and improve the evaporation

and recovery rate.

Bath can be lift and vacuum feeding reduced the breakage of

rotating glass flask. When evaporation under low boiling point,

receiving bottle can be immersed into the ice bath to reduce the

second evaporation.

Receiving flask use ball-milling mouth for connection, can remove

easily and reach high performance sealing.

Packing and delivery

We have good cooperation with many international express companies,

such as DHL/ UPS/ FedEx/ TNT and other, as well as large shipping

companies providing air shipping and sea shipping.

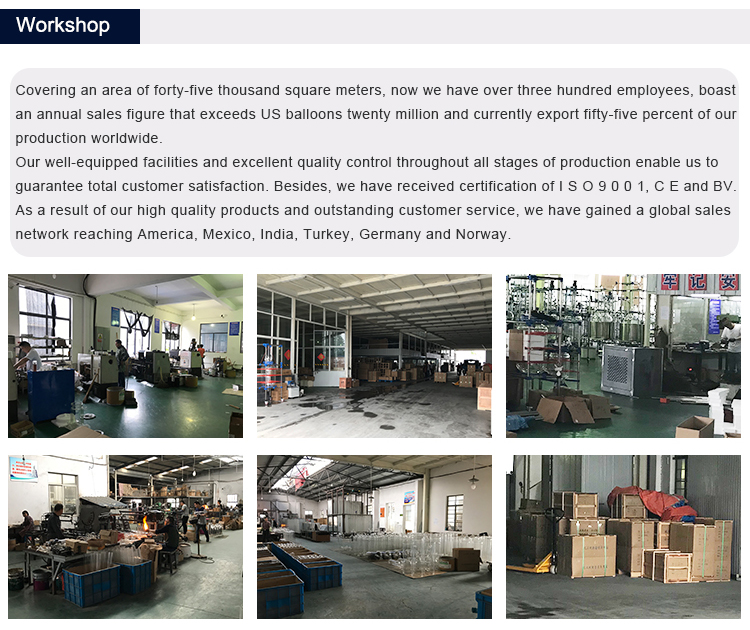

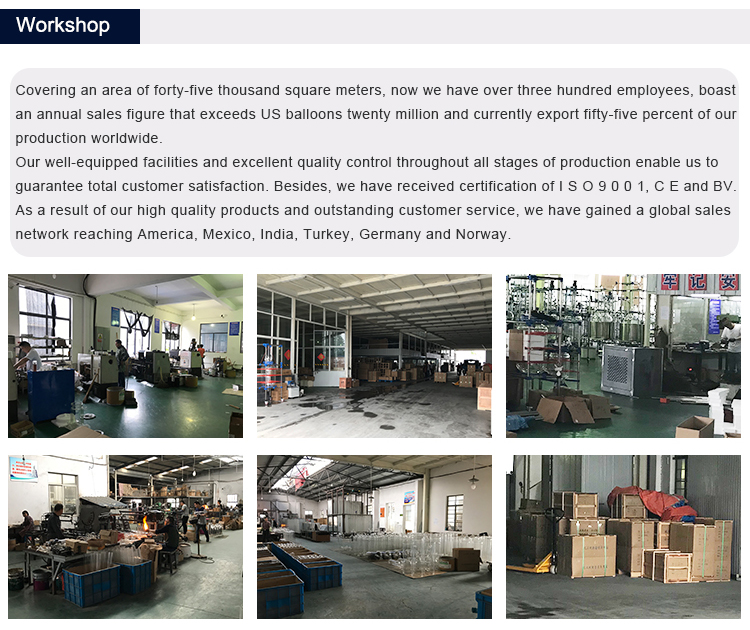

Our factory

Established in 2006, Nantong Sanjing Chemglass Co., Ltd. is a

manufacturer and trader specialized in research, development and

production of chemical glass instrument. Main products include

glass reactor, wiped film evaporator, rotary evaporator, short-path

molecular distillation device and chemical glass tube.

FAQ

Q1: Can you provide OEM or ODM service?

A1: Yes, we have strong developing team to support OEM and ODM

service. The products can be made according to your request.

Q2: What's your MOQ?

A2: Any quantity is acceptable for your order. And the price is

negotiable for large quantity.

Q3: What is your terms of delivery?

A3: FOB/ CIF /Door to Door/By air as you like.