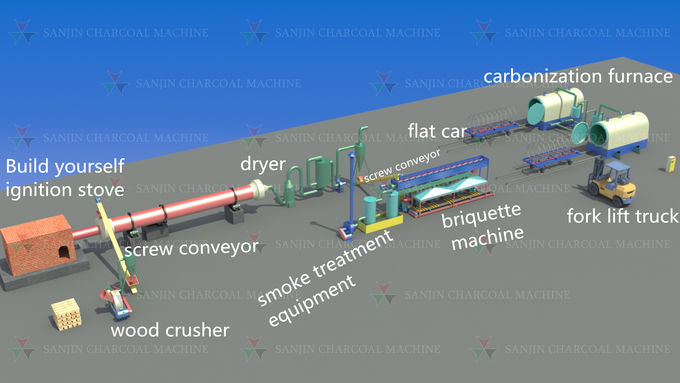

Introduce:

The charcoal machine assembly line designed and produced by our

factory integrates the advanced mechanism of charcoal briquette

forming technology, equipped with briquette making machine, dryer

system, closed twisted dragon feeding, drying raw material cooling,

crushing, conveying as one design, double spiral circulation

feeding, automatic briquette breaking, automatic smoke exhaust

design. This whole set of technological process is to save manpower

and expenditure, and realize the assembly line operation of

mechanism charcoal briquette production.The whole process is done

because of the airtight and dustproof no smoke, dust, the working

environment is very good. Fully embodies the people-oriented design

concept, expand production capacity, increase efficiency, save

labor and labor intensity. From 3 to 8 sets briquette making

machine can be designed into a fully automatic assembly line, the

number of workers operating is 3 peaple, take 6 sets briquette

making machine as an example, complete set of equipment is made of

simple dryer and briquette making machine.The operation of dryer

needs 3 people, the division of drying raw materials needs 1

person, the operation of 6 sets briquette making machines needs 6

people, and the collection and placement of briquette needs 1

person. 11 -- 3=7, we saved 7 workers' wages and management

trouble.Therefore, as long as the customers with sufficient raw

materials should first consider automatic assembly line equipment.

Technical advantages of charcoal machine assembly line:

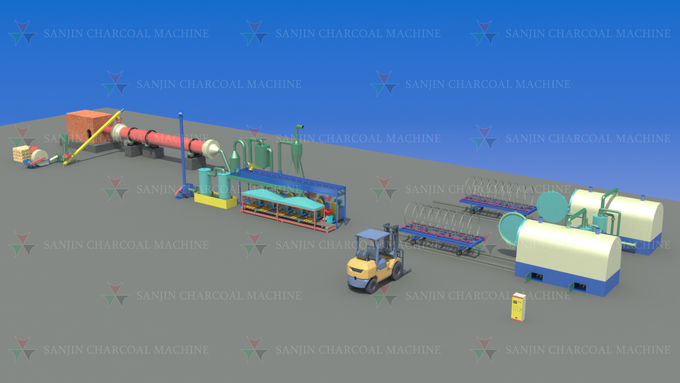

1. This equipment can fully realize the assembly line operation of

charcoal, and fully realize automation from the cleaning, drying,

discharging, cooling, conveying, distribution, making briquette,

briquette breaking and briquette conveying of raw materials. Reduce

the original single machine operation from 12 people to 3-4 people,

the hourly output of briquette can reach 1.2-2.0 tons, reduce the

input of human and material resources, increase the output and

expand benefits!

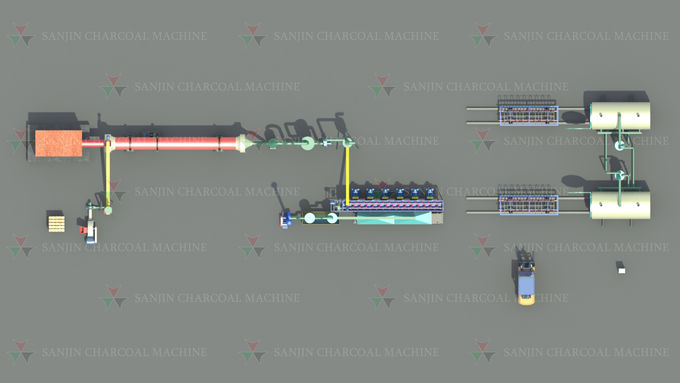

2. The equipment is equipped with 1500 type large pipe diameter

drying system with good effect and high output. Due to the assembly

of drying temperature display control function, can be used for

different raw materials with different temperatures for equipment

startup control, achieve the effect of one-time drying. So even

water soaked raw materials can be one-time drying, and the capacity

will not be reduced. For the ownership of the briquette machine to

start up the normal operation of the foundation.

3. We use MB JWB series infinitely variable speed motor for the

transmission part of the whole equipment. This kind of motor is

adjustable speed, that is to say, according to different raw

materials, different dry moisture to adjust the raw material

conveying speed, quantity.

4. The comprehensive protection function of the motor, this

function can effectively protect the high-power motor from tripping

in the absence of phase and overload, reducing the risk of motor

burnout and realizing automatic flow operation.

5. The starting configuration of the main fan motor of the dryer is

configured for the safe start of the star triangle. The bearing of

the main fan is designed as an oil-immersed water-cooled bearing

box, and the bearing never heats up to prolong the service life.

6. All the auger blades of the conveying equipment, we use

cold-rolled continuous blades, which are very rigid and will not be

twisted and buckled.

7. The powder system of the equipment is designed with double auger

design , the raw materials are evenly distributed, and it has a

unique anti-overflow function. The remaining material of the

distributor can be re-entered into the cooling fan through the

return line.

8. All material separators are auger discharge design, which limits

the presence of dust and spark, improves the production environment

and eliminates potential safety hazards.