Shaanxi Rongbao Machinery and Electronics Co.,Ltd. |

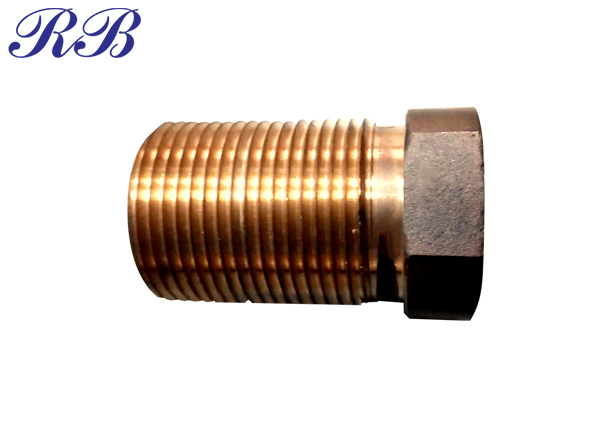

Product Description

| Material | Copper Alloy |

| Process | Investment Casting |

| Color | Natural |

| Casting Surface Roughness | Ra 12.5μm |

| Casting Dimension Tolerance | CT7-CT8 |

| Dimension | Custom-made |

| Testing | Dimension testing, Surface testing |

| Shipping Package | 1. Exported Standard pallets included carton package; 2. Exported Standard Wooden crate; 3. Do package as Customer required. |

Casting method selection:

(1) Sand Casting:

This is one of the most widely used castings. It's mould can be made in wood or metal. The precision of wood mould casting is low, needs to leave large machining allowance for machining. Wooden model manual molding production efficiency is low, suitable for single small batch production or large parts of the casting. Metal mold machine molding production efficiency, casting accuracy is high, but the cost of equipment, casting weight is also limited, suitable for mass production of small and medium-sized castings.

(2)Gravity Casting

A casting in which molten metal is poured into a metal mold and filled with a metal cavity at its own weight. This kind of casting has higher precision, better surface quality, better mechanical properties and higher production efficiency than sand mold casting.

(3) Pressure Casting

A casting in which molten metal is injected into a metal cavity at a high rate under a certain pressure. The casting precision is high, it can reach IT11~IT13; The surface roughness is small, up to Ra3.2~0.4 m. Good mechanical properties of casting. It can be used to cast all kinds of complicated parts, such as holes, threads, characters and patterns. But it requires an expensive set of equipment and a cavity mold. It is suitable for large batch of non-ferrous metal castings with complex shapes and small sizes.

(4) Precision Casting

The paraffin is molded and pressed into the same wax parts as the workpiece through the cavity, and then the special sand is pasted around the wax workpiece, which is dried and roasted after solidification. The wax is evaporated and released, leaving the mold shell of the workpiece shape for casting. Precision casting has high precision and good surface quality. Generally used to cast steel casting complex shape, can save materials, reduce costs, is an advanced blank manufacturing process.

Services We Offer

● Casting Process:

Sand Casting, Die Casting, Low pressure die Casting, Gravity Casting, Investment Casting, CNC Machining

● Surface Treatment:

Heat Treatment, Sand Blasting, Polishing, Power Coating, Chrome Plating, Anodizing, Electroplating

● Material:

Aluminum Alloy, Stainless Steel, Copper Alloy or according to your need

● CNC Machining:

CNC Turning, Milling, Drilling, Grinding, Cutting, Reaming and Threading

Product Image