ERBIWA Mould Industrial Co., Ltd |

|

Verified Suppliers

|

|

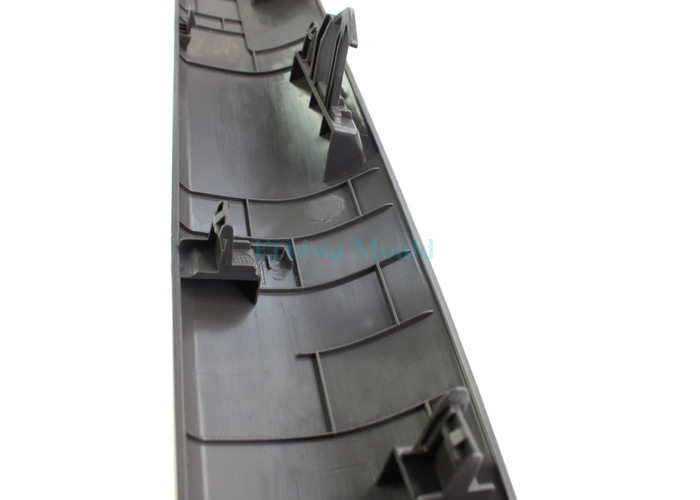

High Hardness Car Bumper Molding For Brown Exterier Fenderguard / Front Below

Description:

1. Car Bumper

3. High quality CF material

4. Super light weight

5. Excellent fitment. Easy installation

6. Aggressive new look

7. All of our products are gel-coated and highly inspected before

shipping

| Company Name | ERBIWA Mould Industrial Co., Ltd |

| Location | Dongguan Guangdong, China |

| Main Product | plastic mould, tooling, injection molding product, such as part from Auto, Medcial, Aerospace, Houseware, VR machine... |

| Business type | manufacturer |

| Quanlity system | ISO 9001: 2015; IATF 16949: 2016 |

| Mould base | SD,LKM Standard, HASCO Standard Self-made, etc. |

| Mould material | P20/718/738/NAK80/S136 |

| Material | Plastic |

| Mould life | 300,000-1000,000shots |

| Cavity | Single/multi |

| Runner | Hot Runner Cold Runner |

| Surface treatment | Polishing/painting/texture etc. |

| Package | Wooden/Plywood case for tool ,PE bags add export carton for parts |

| Lead time | 3~4 weeks after mould confirmation |

| Payment terms | T/T |

| Export country | Europe countries,USA,Mexico,Australia ,Middle-east ,Asia etc |

| Application | Bearings, cams, gears, handles, plumbing components, rollers, rotors, slide guides, valves, knobs, lenses, housings, panels, trays, toys, frames, bushings, gears, covers, seals, sheilds, caps, electrical insulation, housewares, medical tubing, washers |

Advantages of our auto car parts injection :

We have a professional tooling design team with several years experience.

1. Various materials and short lead-time

2. Good steel and long lifetime .

3. We can supply "one-stop" service with molds opening, injection,

painting, screen printing, assembly and nice after-sales service in

long term

4. Full set of machines for mold making and injection molding

5. OEM&ODM service available

6. Mould's design based on tooling engineer from our company and

experienced with years in the dustry.

7. Mould's steel as per customers' requests such as NAK80,

S1369(H),2738, 718, 738 and etc.

8. Final products' materials' optional: ABS, PP, PE, POM,

PA6(66)+GF, PC, PMMA, HIPS, GPPS and etc.

9. Products' color: As the customer's requirments, any color is

possible, if they could provide us the color card schedule.

10. Relevant requirements reachable: RoHS, UL, or as the request.

11. Certifications Authorized: ISO9001&ISO14001 Certificated.

12. Japanese standard of QC management and Euramerican standard of

checking.

13. Service scope: Open mould, Injection, CNC processing, coating,

screen printing, assembly for finished products and so on.

14. Good cost and high effeciency of delivery.

We supply OEM service. We can do customize package if you have your own designs. We can customize color box, white box, blister card package, insert card package, PE bag etc. We can do private labels on the package. We can print logo/brand on the product. All service is based on small MOQ of 1000 units usually.