ERBIWA Mould Industrial Co., Ltd |

|

Verified Suppliers

|

|

►Product Description

| Details of Mould | |

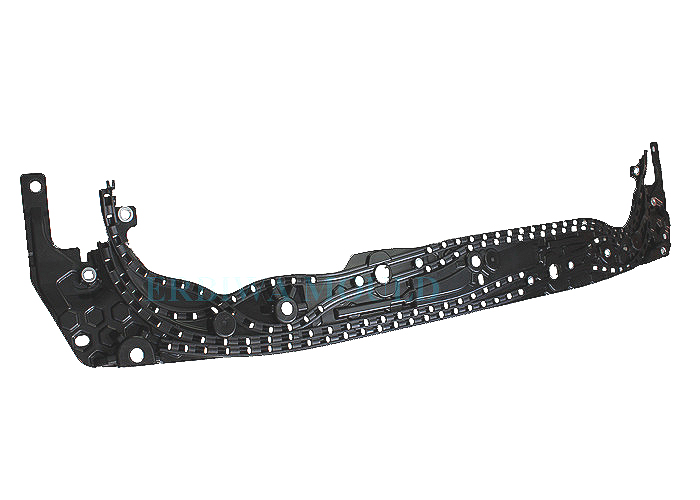

| Item Name | High precision injection molded parts with metal insert for brand new car durable stiffener |

| Mould Material | NAK80, S136, 2316, 2738, H13, 718H, 738H, P20, etc |

| Product Material | PET, PBT, PPS, PA6/PA12, LCP, PPE+PS, PPI, ABS, PC, ABS+PC, POM, PP, etc |

| Cavity No. | Single or Multi |

| System Of Runner | Hot runner, Cold runner, Pin-point gate, Submarine gate, etc |

| Ejector Type | Ejector pin, Ejector plate, Hydro-cylinder, etc |

| Lead Time | 35-60 Days |

| Cycle Life | 100K-1000K Shots |

| Mould Design Software | UG, ProE, Solidworks, AutoCAD, Moldflow, ect |

| Brief Mould Manufacturing Procedure | |

| Product Design | Customer send the product drawing to us directly or we make the product design according to the sample then send to customer for confiration |

| Mould Design | After the product drawing approval, then send the mould design to customer for confirmation |

| Mould Making | After mould design approval, the process include prepare material, rough cut, finish machining, assembly, etc |

| Mould Test | After finishing mould assembly, then we'll send trial samples, video and try-out report to customer for confirmation |

| Final Process | If the sample approval, making grain, nitridation or chroming if customer required |

| Mould Test | Re-test the mould, then send the final sample and video of test to customer for checking |

| Mould Packing | Pack the mould with wooden case after the final sample approval |

| Mould Delivery | By sea or air. The forwarder can be designated by your side |

► Mould Process

| 1 | Quotation | Need 2D/3D drawing or Samples |

| 2 | Mould Design | Mould design drawing could be sent for confirmation in one week after receiving the down payment |

| 3 | Mould Making | Start mould manufacturing only after the mould design is confirmed by customers |

| 4 | Mould Trial | 1st shot samples will be available for checking |

| 5 | Sample Confirmation | Customer to check and confirm samples |

| 6 | 2nd Payment | Customer need to pay for the 2nd payment once received the T1 shot samples |

| 7 | Mould Modification | Modify the mould if necessary |

| 8 | Mould Delivery | To deliver the mould after received the 3rd payment |

| 9 | After-Sales Service | Free of charge for 12 months warranty |

| 10 | Unpaid Balance | Customer need to pay for the balance after molds having been shipped out two months |

Attention:

Pease offer the following information when you send us the mould inquiry.

a) product drawing or the sample photo with sizes.

b) mould steel you want to use.

c) standard mould base or not.

d) runner system you want(cold or hot).

►Our Services

1. We are a one-stop production provider, and we can supply you with Research&Development, mould manufacturing, Injection molding, Secondary process and product assembly.

2. Equipment: High Precision CNC, High peed Miller, Deep hole Drilling machine, EDM, Wire Cut,

Grinding Machine, Fitting process machine, Injection Machine etc.

3. Design: we have more than 7 mold desingers and 3 CNC Engineers with rich experience. UG CAD and UG NX4 CAM for design and manufacturing and AutoCAD2007 for 2D layout.

4. Mould design is subject to customers’ requirements. We will prepare DFM report and mold flow analysis report if customers need.

5. Heat treatment of mold (Hardening) can be provided including quencher, nitridation, tempering, etc.

6. After-sales service: 12months warrenty(free of charge).

►Our Advantages

1. Professional and experienced workers

2. Advanced technology and equipment

2. Competitive price & OEM design

3. Design drawings for free

4. Injection mold production more than 15 years of experience

7. We use eco-friendly material

8. A very strict quality controlling system

9. Delivery on time

►Our Quality Control

We have good QC system, covering IQC, OPQC, OQC

For the Q/C of mould, there are 3 steps:

1. Mould Material Q/C

- Mould Steel Checking (Hardness, flaw detection)

- Mould Standard Spare Parts Checking (hardness, size, flaw checking)

2. Mould Making Process Q/C

- design checking (part design, mould design, mould engineering drawing)

- each part of mould’s size checking after machining according to 2D drawing

- mould testing (check mould running condition)

3. Check with customer’s requirement again before mould shipping

► Product Show

RFQs are always welcome, we sincerely hope to cooperate with clients from home and abroad.

Kindly contact me if any questions. It is our pleasure to be on service of you.