Tungsten Carbide Guillotine Shear Blades , Replacement Blade For

Guillotine Paper Cutter

Products Introduction:

Straight Guillotine Bladeinclude hot rolling and cold rolling

straight blade. For hot rolling applications, Straight blade are

usually made of high quality steels, like nickel alloy. However,

for cold rolling applications, medium quality and high quality

alloy tool steel and heavy-duty powder metallurgy steel are usually

adopted for making straight blade for cold rolling applications.

Shear blade for plate shearing machines with different sizes and

specifications are all available to satisfy customers' different

cutting needs.

Passiontool, a professional manufacturer of Paper Industry machine

knives, including cross digital blade etc. We have these blades

available in wide range of dimensions, and can also make customized

blades as per customers' requirements and drawings. Welcome to

inquire with your drawings or samples.

Blades Application:

Of course, we can also manufacture industrial blades else:

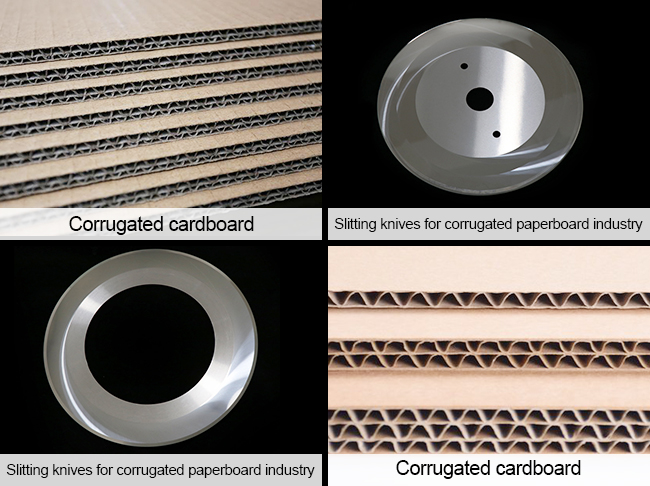

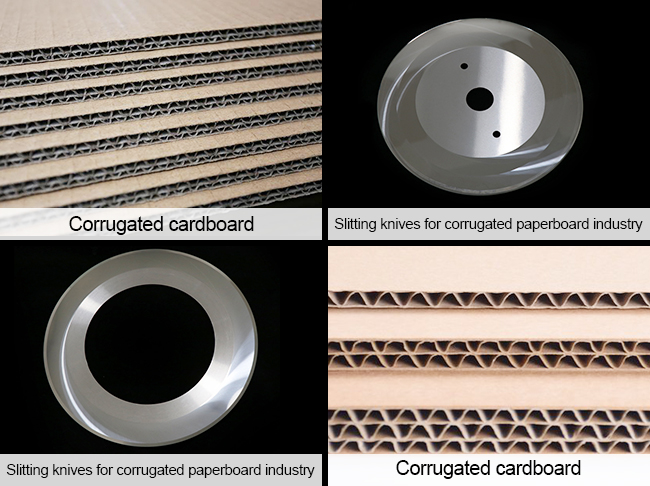

| Slitting knives for corrugated papers; | Guillotine blades for papers and metal sheet cutting; |

| Top and bottom shear blade for film, foil, plastic, papers cutting; | Dished blades for converting blades; |

| Oscillating knife, tangential knife, drag knife for automatic

cutting tables; | Circular carbide ring for metal sheet cutting; |

| Slitting blades for cigarette and tobacco industries; | |

Sintering Vaccum and HIP Technology:

HIP Process

1. Fine porosity would be remained in Powder metallurgy of

processing for Tungsten Carbide, which will be the beginning of

destroy of products.

2. To remove this fine porosity, we PASSION produce products

through HIP Process.

3. This process is progressed under the high temperature and

pressure, and put the identical pressure on whole surface of

product.

4. At this time, a fine porosity would be removed, and effected on

improving high strength.

Inspection, Clearning and Package:

Inspection:

In order to supply good blades to customers, we will check all

products to see if there were any nicks.

PASSION blades are strictly checked over 20 inspection process from

powder to completed. We can keep and improve our quality, and are

very pleased to hear that customers are satisfied with our

stabilized products.

Clearning:

Our warehouse team will clear every blades and check it before

package.

Package:

poly bag, foam box, vaccum package, carton or customer

requirement.

Company profile:

1. Twenty years experience

2. We are END MANUFACTURER

3. We promise that use 100% original materials

4. Competitive price

5. Passed the ISO9001 quality certification.

6. OEM and ODM possible

7. Specializes in manufacturing all kinds of cutting tools,

including slitting knives ,shearing blades, cutting blades,

guillotine etc

8. Materials choices solid carbide 5CrW2Si, 6CrW2Si, Cr12MoV,

9CrSi, H13 and self-developed H13k, high various alloy steel

9. Blade High intensity, high hardness, high toughness, and high

harden ability, etc.

10. Blades Widely used in industries of steel, rubber, paper mills,

etc.

FAQ:

Q: Are you trading company or manufacturer ?

A: Our factory is a professional manufacturer of machinery blades

for more than 20years.Our blades are mainly used in: packaging,

paper, rubber, electronics, light industry, printing, metallurgy,

and other machines.

Q: What is your advantage if I choose you?

A: End manufacturer with competitive factory price.

Different raw materials for you to choose, we can give a

professional suggestion to you.

Various blades for you to choose, OEM&ODM is supported.

High wear resistance and waterproof. Short delivery time & safe

packaging.

Q: How long does it take to manufacturer a machine knife to

customized specification.

A: Our normal lead time is 35days to 40days. Some special knives,

such as metal sheet shearing blades, and carbide inlaid blades. we

need more times(45days to 50days). because these special knives

need more time to grind carefully. We also make some ready stock of

standard dimensions. So, please contact with our sales. We will

check stock per your requirement.