Zhuzhou XinHua Cemented Carbide Co., Ltd. |

|

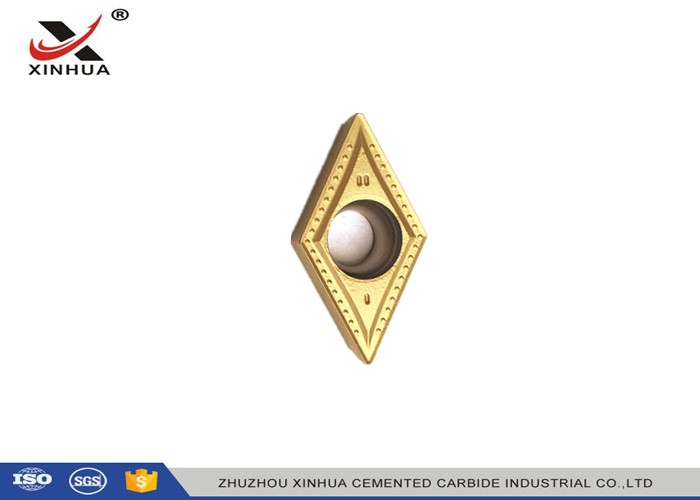

TiN Coated Cermet Insert DCMT11T304-MT Replacement of Taegutec with High Cutting Speed

Description:

1. 100% virgin raw material of powder for each insert to ensure you top and stable quality.

2. High technical production line to ensure delivery on time.

3. More than10,000 sets of of molds with various of types, sizes, chipbreakers and coating for customer to choice to meet customers requirements. Also we accept special design to open new mould according to customers drawings and samples.

4. Different packages :different color /brand/size of inner plastic box and outside wooden box .

5. 24 hours on line for sales and after sales service and in time technology supports.

Solid carbide provides better rigidity than high speed steel. It is extremely heat resistant and used for high speed applications on 45steel, cast iron, nonferrous materials, plastics and other tough-to-machine materials.

Product features

|

Application:

Features of cermet inserts

Cermet grades provide long tool life and excellent surface finish, combining toughness with superior wear resistance.

PVD-coated cermet has high abrasion resistance and fracture resistance thanks to the use of the PVD coating technology (Physical Vapor Deposition) on a basis material of micro-grain carbide.

The substrate is coated by the PVD method with TiN, TiCN, and/or TiAlN. The end results are materials that are suitable for precision machining and machining of difficult-to-cut materials. Inserts in these grades are tougher and harder than carbide and come with precision sharp cutting edges. They even have superior toughness and sharper cutting edges than ultra micro-grain carbide grades, with excellent wear resistance and thermal crack resistance.

Cermet is a cutting tool material composed mainly of TiC (Titanium

Carbide) and TiN (Titanium Nitride). The name, cermet, is derived

from the words CERAMIC and METAL (representing carbide).

As the name suggests, cutting performance is also in the mid-range

of ceramic's and carbide's. The advantages of this material grade

are

high-quality and excellent surface finishes can be achieved with

elevated cutting speeds. Cermets provide extended tool life.

Specification:

| item name | DCMT11T304-MT |

| Place of Origin | Zhuzhou |

| Model Number | various |

| Workpiece | Steel |

| Application | Turning |

| Color | Gold |

| Hardness | various |

| Coating | TiN Coated |

| Material | Tungsten Carbide |