Zhuzhou Zonco Sinotech Wear-resistant Material Co., Ltd. |

|

Manufacture OEM Planetary Ball Mill Tungsten Carbide Grinding Jar

Applicated for tungsten carbide ball mill jar is used as grinding

jar of planetary ball mill matched with tungsten carbide

balls,which is suitable for grinding materials in high hardness

such as hard alloy powder,diamond powder and silicon carbide

powder.

| Jar volume | 25mL-1000ml |

| Max loading capacity | 2/3 capacity of the grinding jar |

| Density | 15.5g/cm³ |

| Main chemical compositions | WC(94%,92%,85%),cobalt(6%,8%,15%) |

| Surface treatment | blank or finish |

| Abrasion resistance | good |

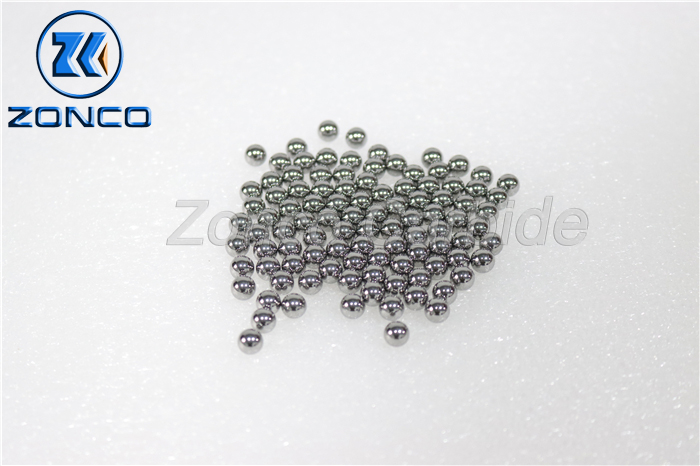

| Grinding balls | mixed tungsten carbide ball(should be ordered separately) |

| Hardness | 92.1HRA |

Grinding jars & balls configurations

| Jar Volume | 50ml | 100ml | 250ml | 500ml | 1000ml |

| Ø6mm | 50 pcs | 100 pcs | 280 pcs | 500 pcs | 1000 pcs |

| Ø10mm | 8 pcs | 16 pcs | 40 pcs | 100 pcs | 200 pcs |

| Ø20mm | 2 pcs | 3 pcs |

Common volume size

| Volume | H (mm) | OD (mm) | ID (mm) |

| 50 ml | 70 | 48 | 36 |

| 100 ml | 63 | 63 | 51 |

| 250 ml | 79 | 86 | 74 |

| 500 ml | 106 | 105 | 90 |

| 1000 ml | 135 | 130 | 115 |

Products show

Common tungsten carbide grades

| Common Alloy Grades, Ghysical Mechanical Properties And Recommended Application | |||||||

| Grade | WC% | Co/Ni % | Physical and mechanical properties | Grain size (μm) | Recommended application | ||

| Density (g/cm3) | TRS (N/mm2) | Hardness (HRA) | |||||

| ZG01 | 100 | 0 | 15.3-15.5 | 1200 | 95.5 | 0.3 | Ultra-high hardness, high wear resistance, anti-corrosion, with certain anti-destructive ability |

| ZG04X | 96 | 4 | 15.0-15.2 | 1600 | 92.8 | 0.8-1.0 | Suitable for drawing die, non-ferrous metal wire drawing and wear-resistant parts |

| ZG06 | 94 | 6 | 14.8-15.1 | 2500 | 90.0 | 1.2 | Good abrasion resistance, good compression resistance, suitable for wear-resistant parts that resist abrasion and high pressure. |

| ZG06X | 94 | 6 | 14.8-15.1 | 2400 | 91.5 | 1.0 | Superio wear resistance,good comprehensive properties,suitable for making non-standard structure components with higher wear resistance. |

| ZG06A | 94 | 6 | 14.8-15.1 | 2150 | 92.5 | 0.6-0.8 | |

| ZG08 | 92 | 8 | 14.6-14.9 | 2700 | 89.0 | 1.2-1.6 | Good general performance, used for general wear parts, molds, general tools, etc. |

| ZG10.2 | 90 | 10 | 14.3-14.6 | 3800 | 91.7 | 0.7 | Good general performance, suitable for casing and oil nozzle products |

| ZG11 | 89 | 11 | 14.3-14.7 | 2800 | 88.5 | 1.2-1.6 | Anti-wear, anti-erosion, good comprehensive mechanical strength, suitable for wear-resistant parts in the petroleum, chemical and mechanical industries. |

| ZG12X | 88 | 12 | 14.2-14.5 | 3000 | 89.5 | 1.0-1.2 | Anti-erosion, good comprehensive mechanical strength, suitable for impact-resistant wear-resistant parts, molds, and roller rings. |

| ZG15 | 85 | 15 | 13.8-14.2 | 3000 | 86.5 | 1.2-1.6 | |

| ZG15X | 85 | 15 | 13.8-14.2 | 4500 | 89.0 | 0.7 | Excellent wear resistance and toughness,it is suitable for making integral stamping dies, anti-vibration toolholders, etc. |

| ZG20 | 80 | 20 | 13.4-13.8 | 3100 | 85.0 | 1.0 | Excellent wear resistance and toughness |

| ZN06 | 94 | 6 | 14.5-14.9 | 2000 | 90.0 | 1.2 | Non-magnetic alloy, suitable for sealing ring, non-magnetic wear-resistant parts and corrosion-resistant parts. |

| ZN09 | 91 | 9 | 14.3-14.6 | 2300 | 89.0 | 1.2-1.6 | |

| ZN11 | 89 | 11 | 14.0-14.3 | 2600 | 88.0 | 1.2 | |