Zhuzhou Zonco Sinotech Wear-resistant Material Co., Ltd. |

|

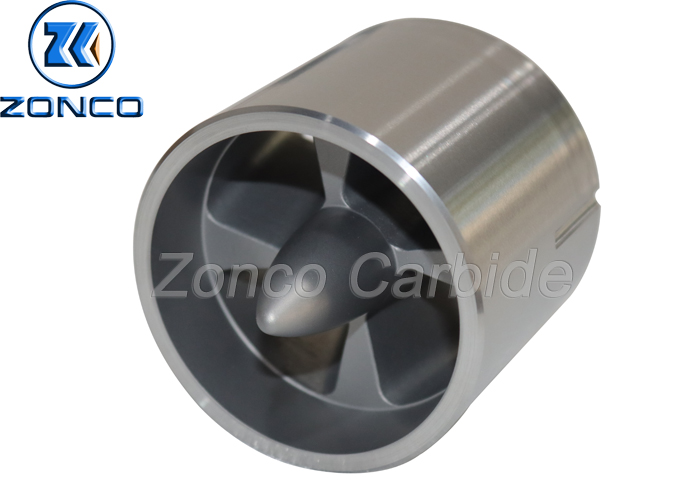

An Extreme Precision Measurement While Drilling Components For The Oil And Gas Industry

As drilling has become more complex, with horizontal and directional drills increasing in numbers, well logging has also had to adapt and improve. Measurement-While-Drilling (or MWD) is a type of well logging that incorporates the measurement tools into the drillstring and provides real-time information to help with steering the drill.

Once a well angle exceeds 60 degrees, the logging tools can no longer be pushed through the well to retrieve information, making conventional logging tools ineffective. Originally designed in the 1980s to overcome well logging challenges of wells being drilled at extreme angles, MWD is a type of Logging-While-Drilling (LWD) where tools are encompassed in a single module in the steering tool of the drillstring, at the end of the drilling apparatus (or the bottom hole assembly).

Providing wellbore position, drillbit information and directional

data, as well as real-time drilling information, MWD uses

gyroscopes, magnetometers and accelerometers to determine borehole

inclination and azimuth during the actual drilling. The data is

then transmitted to the surface through pulses through the mud

column (mud pulse) and electromagnetic telemetry. Decoded at the

surface, the data can also be transmitted to an offsite location

immediately.

With such precise wells being drilled, MWD aids drilling engineers with real-time information so that they can make important decisions while drilling. Geosteering is a relatively new concept of positioning wells according to the geological features in the reservoir obtained through MWD.

Please check below new photo

Common Alloy Grades, Ghysical Mechanical Properties And Recommended Application | |||||||

| Grade | WC% | Co/Ni % | Physical and mechanical properties | Grain size (μm) | Recommended application | ||

| Density (g/cm3) | TRS (N/mm2) | Hardness (HRA) | |||||

| ZG01 | 100 | 0 | 15.3-15.5 | 1200 | 95.5 | 0.3 | Ultra-high hardness, high wear resistance, anti-corrosion, with certain anti-destructive ability |

| ZG04X | 96 | 4 | 15.0-15.2 | 1600 | 92.8 | 0.8-1.0 | Suitable for drawing die, non-ferrous metal wire drawing and wear-resistant parts |

| ZG06 | 94 | 6 | 14.8-15.1 | 2500 | 90.0 | 1.2 | Good abrasion resistance, good compression resistance, suitable for wear-resistant parts that resist abrasion and high pressure. |

| ZG06X | 94 | 6 | 14.8-15.1 | 2400 | 91.5 | 1.0 | Superio wear resistance,good comprehensive properties,suitable for making non-standard structure components with higher wear resistance. |

| ZG06A | 94 | 6 | 14.8-15.1 | 2150 | 92.5 | 0.6-0.8 | |

| ZG08 | 92 | 8 | 14.6-14.9 | 2700 | 89.0 | 1.2-1.6 | Good general performance, used for general wear parts, molds, general tools, etc. |

| ZG10.2 | 90 | 10 | 14.3-14.6 | 3800 | 91.7 | 0.7 | Good general performance, suitable for casing and oil nozzle products |

| ZG11 | 89 | 11 | 14.3-14.7 | 2800 | 88.5 | 1.2-1.6 | Anti-wear, anti-erosion, good comprehensive mechanical strength, suitable for wear-resistant parts in the petroleum, chemical and mechanical industries. |

| ZG12X | 88 | 12 | 14.2-14.5 | 3000 | 89.5 | 1.0-1.2 | Anti-erosion, good comprehensive mechanical strength, suitable for impact-resistant wear-resistant parts, molds, and roller rings. |

| ZG15 | 85 | 15 | 13.8-14.2 | 3000 | 86.5 | 1.2-1.6 | |

| ZG15X | 85 | 15 | 13.8-14.2 | 4500 | 89.0 | 0.7 | Excellent wear resistance and toughness,it is suitable for making integral stamping dies, anti-vibration toolholders, etc. |

| ZG20 | 80 | 20 | 13.4-13.8 | 3100 | 85.0 | 1.0 | Excellent wear resistance and toughness |

| ZN06 | 94 | 6 | 14.5-14.9 | 2000 | 90.0 | 1.2 | Non-magnetic alloy, suitable for sealing ring, non-magnetic wear-resistant parts and corrosion-resistant parts. |

| ZN09 | 91 | 9 | 14.3-14.6 | 2300 | 89.0 | 1.2-1.6 | |

| ZN11 | 89 | 11 | 14.0-14.3 | 2600 | 88.0 | 1.2 | |