Zhuzhou Zonco Sinotech Wear-resistant Material Co., Ltd. |

|

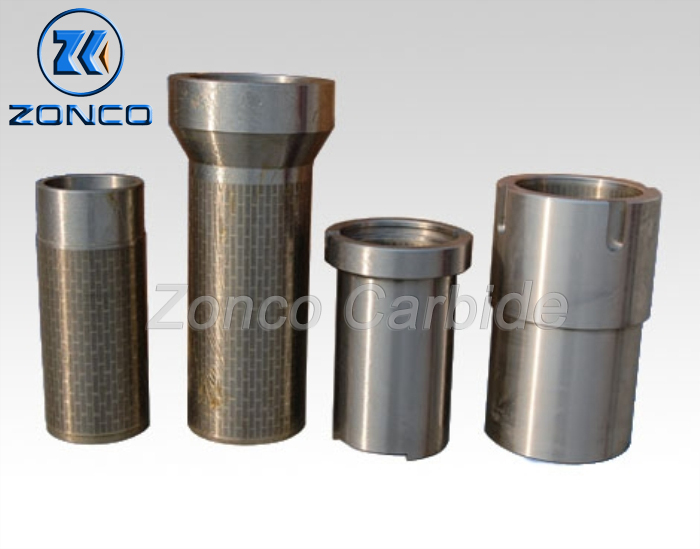

Mud Stack Thrust Angular Contact bearing,Mud Motor Bearings

| Product Name | Mud Stack Thrust Angular Contact bearing,Mud Motor Bearings |

| Brand | Zonco |

| Material | 100% Virgin Steel/Tungsten carbide |

| Workpiece | Downhole motor |

| MOQ | 1 Piece |

Product Description

The bearings in a mud motor at the end of a drill string would

place a huge influence on productivity and reliability in terms of

oil

drilling or gas drilling.The working condition of these mud motor

bearings are extremely harsh: the bearings bear heavy axial and

shock loads, and they are also exposedwith highly abrasive mud.

• Special steel for all bearing components

• Full complement bearing

• Precision matched rings

• Unique bearing design to support heavy

• axial drilling loads

Downhole drilling motor bearings

Whether you’re drilling for oil or gas, the bearings in a mud motor at the end of a drill string have a direct impact on productivity and reliability.These mud motor bearings have to endure extreme operating conditions. In addition to severe axial and shock loads, these bearings are “lubricated” with highly abrasive mud, which for a bearing is the definition of an extreme operating condition.

How the new bearing works ?

The typical mud motor bearing contains between 8 and 12 rows for design optimization. When the bearing is new, the majority of the load is accommodated by the first four or five rows. As each row starts to wear, the load is shifted to the next row and the next until all the rows are worn equally. Then, the load is shifted back to the first row and the process is repeated. This unique design enables the bearing to last significantly longer than previous bearing designs.

About the redesign process

To significantly improve bearing performance and reliability,engineers used proprietary design and simulation tools to

• accurately define the behaviour of a bearing stack

• redesign the bearing to minimize stresses and optimise load carrying capacity

• test new designs and materials. With the virtual test rig, engineers were able to identify and correct the problem of cracked rings and sheared balls – two common problems with these bearing

Product features

• Special steel for all bearing components

• Full complement bearing

• Precision matched rings

• Unique bearing design to support heavy axial drilling loads

Customer benefits

• Improved wear-resistance

• Increased load carrying capacity

• Optimized load distribution

• Increased robustness

• Improved reliability

• Customized design

Products show