Zhuzhou Zonco Sinotech Wear-resistant Material Co., Ltd. |

|

For Advantage of our tungsten carbide rod

1. Using over 99.95% high purity tungsten carbide powder, it has a

better strength and hardness combined with a longer service life

than the normal one.

2. Using ultrafine grain size of tungsten carbide powder to

produce,Hardness can reach to HRA93.6, Bending strength can reach

to 4000N/mm²

3.Tolerance can reach to ±0.001mm, straightness can reach to

±0.02mm

Solid Carbide Rod is extensively used for making drill bits, inserts, & end mills of different configurations. It is greatly admired for having rugged construction with optimum surface hardness. This rod shows ability to bear high amount of temperature & impact without any structural wear & deformation. It is provided with nickel coated surface finish with high scratch & abrasion resistance. Offered Solid Carbide Rod can easily be designed with help of CNC machines for assuring high dimensional & structural precision. It can be availed at reasonable rates in bulk for our respected clients. This rod also finds application for making components that are intended for use in nuclear power plants .

The grade of YF06 is suitable for machining composite materials, such as aluminum magnesium alloys, plastics, reinforced plastics and carbon fiber, iron-based alloys etc. It is recommended for making big PCB drills ofΦ3.2-6.3mm, micro drills ofΦ0.8-3.2mm, micro milling tools and reamers etc.

The uses of tungsten carbide rods are divided into two parts: on the one hand they are used to produce finished hardmetal tools, such as twist drills, mills, reamers, taps and burrs etc; on the other hand they are applied to produce processing tools of making printed circuit boards (PCB), such as micro-drills, big-head drills and gravers etc.

Tungsten Carbide Rods’ Grades and Properties:

| Grades | ISO Code | Cobalt Content | Density | Hardness |

| (%) | g/cm3 | HRA | ||

| K10T | K05-K10 | 4.5 – 6.0 | 14.95 – 15.05 | 92.7 |

| YG8 | K30 | 8 | 14.80 | 89.5 |

| YG6 | K20 | 6 | 14.95 | 90.5 |

| YG6X | K10 | 6 | 14.95 | 91.5 |

| YL10.2 | K30 | 10 | 14.50 | 91.8 |

| YG13X | K30-K40 | 13 | 14.30 | 89.5 |

| YG15 | K40 | 15 | 14.00 | 87.5 |

Aplications:Cutting Tool IndustryPCB ToolsDies/PunchesBladesPaper IndustryPolymer ExtrusionGear CuttingOther Wear Parts

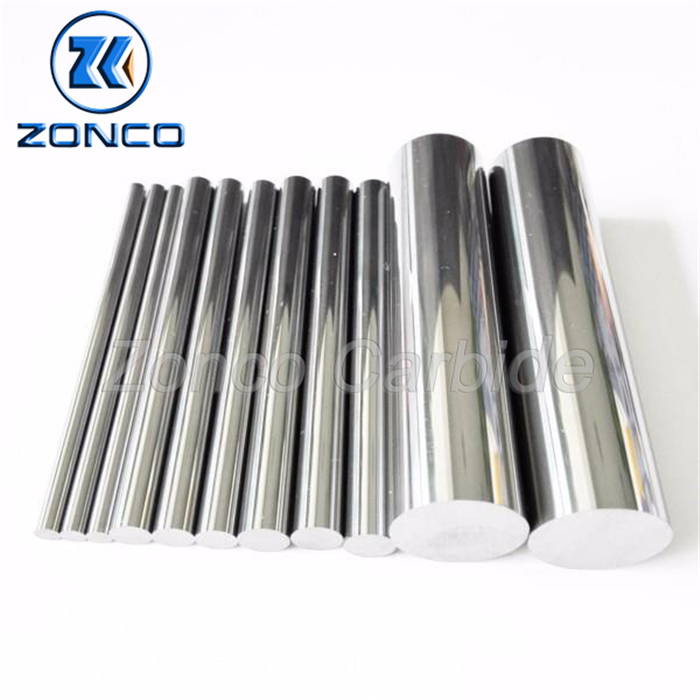

Product show