Jiangyin Bosj Science & Technology Co., Ltd. |

|

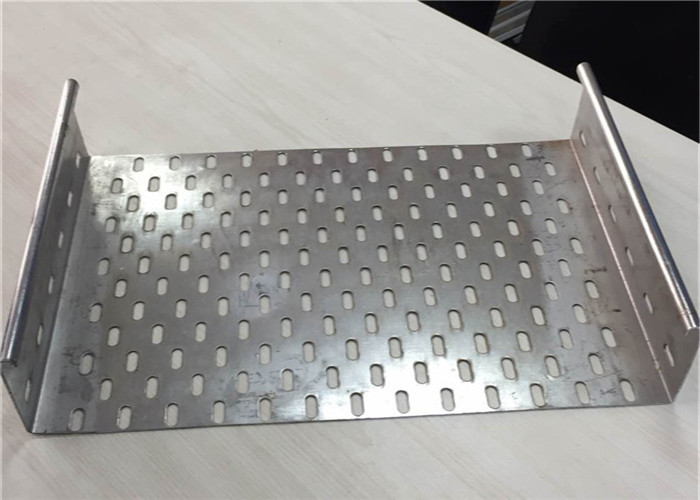

High Sided CT Cable Tray Roll Forming Production Machine factory

Service from BOSJ

BOSJ offer engineers to install and commision the machines at buyer's factory,and also train your workers to operate the machine.

Guarantee: one year after finishing machine installation and commission at buyers' factory.

24 hours response time

a) Mechnical engineering team with 10 actual working experience

b)Electrical engineering team with 10 actual working experience

Cable Tray Roll Forming Machine

| No. | Name | Type and size | Quantity | (KW) Power(kw) |

| 1 | De-coiler | 1 set | ||

| 2 | Straightener | 1 set | 4 | |

| 3 | Servo-feeder | 1 set | 4 | |

| 4 | Punching Press | YANGLI GROUP | 1 set | 25 |

| 5 | Punching Mould | 1 set | ||

| 6 | Conveying Table | 1 set | ||

| 7 | Roll Forming machine | Full automatic control type | 1 set | 15 |

| 8 | Collection table | 1set | ||

| 9 | Electric Control System | 1 set | 7.5 |

1, Equipment capabilities

It can according to the need to produce the steel width (60mm≤§≤860mm), many kinds of specification electric cable bridges and other structure product.

Product speed by punching: 2.55m/min

Continuous rollforming speed: 10-15m/min

Material thickness: 1~2mm

Material require: Q235 cold roll steel

Production line has automatic and manual two operating mode, may realize the linkage and the partition revolution work.

2, Main composition of machine

This unit consists of the decoiler, ML-900 flatting, 200 punch, die, servo feeding, guider, main roll forming machine, follow cutting, cut-to-length part, recoiler, electrical control cabinet; etc.

3,Each part major technical parameters

3.1 Drive decoiler

Material width:860mm

Material weight:6000kg

Material inner diameter:508mm

Material outer diameter:1200mm

Drive power: electromotor and speed reducer integration, 4KW frequency conversion electromotor

Frame type: cantalever inner support, manual handle afterbody, pneumatic press cantalever.

3.2 Leveling machine

a.Working roller: nine rollers type leveling machine

b.Feature of structure: after the quenching and tempering, chrome-plating processing, the rigidity, surface roughness of the roller etc. are all enhance greatly; It is composed by the clamping roller and the leveling roller, the clamping roller may the independent control, the leveler has one pair of horizontal guide roller and two pairs of vertical guider roller and easy to

adjust by hand wheel.

Between the leveler and the feeding device, there is optical sensor, sends out the feedback signal to the control system, the control system sends out the instruction to the frequency conversion motor to change speed to control the storage quantity of the sheet.Achieves the uninterrupted level goal.

3.3 Continual punching mould

Amount: Each kind of width specification 1 set dies, total 6 sets

Die require: Cr12 quench

It finishes punching and cutting in one time.

3.4 Servo feeding Device

Servo electromotor power: 4.4kw

Multistage type feeding, memory ten group of memory functions

Man-machine contact surface numerical control system

Uses Mitsubishi servometer

3.5 Holds material (use in cushion section)

The roller type, the both sides have the bearing support, 3 sets, use in holding the material and under the deposited material spacing.

3.6 Guider

A pair of horizontal roller and two pairs of vertical guide rolls, total 1 sets.

3.7 Main roll forming machine

Main forming machine

a. Type: double hanger gearing drive. Forming width is adjusted by

automatic forming wall moving, it also can adjust height quickly.

b. Insert the sheet plate which already perforated into the machine, through 18 stations to roll as the cable tray. It consists with the speed regulation alternating current machine, reducer, high-precision linear rails, gearbox (left and right side), the crosswise adjusting mechanism and one complete set of rollers. One set of roller can complete all type of the cable tray,type change can through the adjustment of the one side of machine by motor. The main body and the gearbox use the welding structure, de-stressing processing; the material of the gear is the 45 steel hard tooth surface. Forming technology of main forming machine is from Italy, it will guarantee high-precision.

The roller uses the combinated structure, the speed difference and the forming resistance are small, the steel plate surface will be less wear; and also guaranteed the precision shape of the working piece with no scratch .The material of the roller is the GCr15 forging, after whole quenching then by numerical control processing, degree of hardness can reach HRC58-62; Has the characteristic with high strength, hardness, precision and long service life etc.

Electric control system

a. Full line is controlled by PLC control system with touch screen operation to achieve the human and PLC interactive. The operator can monitor the setting program (programmable control) and modify the parameter to control the line. Also can check the running status, parameter and error indication etc...

b. Operation type: manual /auto two type switch. In manual position: can run the each part of the machine. In auto position: can run the full line. The emergency stop ensures the safe of the equipment and operator.

c.Machine side is equipped with the manual operation control panel for convenient worker to operate;

Control styp: manual handle

4,Produce condition

capability: about 71.5kw

gas fountain: 0.9 cube/min

Production land area: 33m*3m

5,Machine Parameter

| NO. | Project | Unit | Parameter | Remark | |

1 | Material | Type | High strength steel | ||

| Strength of material sheet | Map | ≥350 | |||

| Thickness of material sheet | mm | 1.2~2.0 | |||

| 2 | Size of production | mm | Reference the picture | ||

| 3 | Production speed | m/min | Punching speed 4m/min Forming speed 10m/min | ||

| 4 | Material of roller | GCr15 quenching treatment | |||

| 5 | Drive type | Gear | |||

| 6 | Power | kw | About 75 | ||

| 7 | Electric control system | PLC variable frequency control | |||

| 8 | Dimensions(Length*width*height) | m | 55X4X3.9 | ||