Jiangyin Bosj Science & Technology Co., Ltd. |

Roll forming production scope

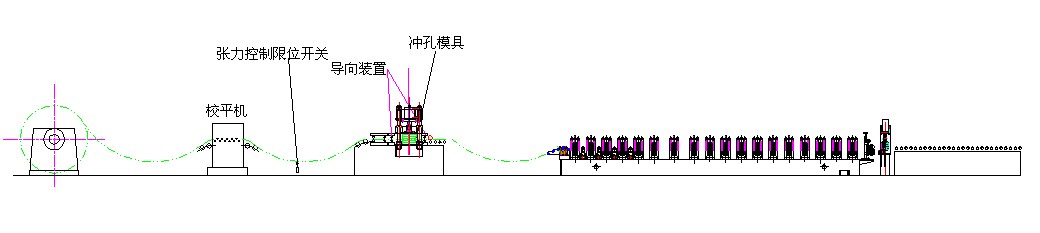

1,Production Forming process

De-coiler—servo feeding—gap and cut off mould—forming ---collection table

2, Flow diagram

3, Equipment composing parts

Equipment is composed of de-coiler ,feed system ,gap and cut off , forming machine,collection table ,electric control system , etc.

NO. | Project | Unit | parameters | Remark | |

1 | Material | type | Mild steel Galvanized sheet | ||

| Strength of material sheet | Map | ≥350 | |||

| Thickness of material sheet | mm | 0.8~1.5 | |||

| 2 | Size of production | mm | Reference the picture | ||

| 3 | Production speed | m/min | 6~8 | ||

| 4 | Material of roller | GCr quenching treatment | |||

| 5 | Drive type | Gear box | |||

| 6 | Power | kw | About 34 | ||

| 7 | Electric control system | PLC variable frequency control | |||

| 8 | Dimensions(Length*width*height) | m | 28X4X3.9 | ||

4, Technical parameter of equipment main parts

Servo feed and punching unfilled corner parts

a , Servo motor : used Mitsubishi Servo motor , power: 1.0kw

b , Punching unfilled corner die: 4 pillars punching die

c , Material of punching die: Cr12. quenching treatment

8 - Electrical control system

1-The whole line adopts PLC control, LCD touch screen display and

man-machine interface software. (Interaction between workers and

PLC. )

The operator can do the following

The setting program (PLC)

Monitoring the control process,

Modify the control parameters,

The length of the workpiece digital setting,

The length of the workpiece adjusting.

Running state real-time monitoring equipment and fault indication.

5.Product Pictures