Jiangyin Bosj Science & Technology Co., Ltd. |

|

Unistruct Solar Stand C Channel Roll Forming Machine

Normal Sizes:41X21mm/41X41mm/41X61mm/41X72mm or other sizes required by your actual usage.

BOSJ offer sample design,or you can offer your sizes.We will offer you the suitable technical proposal and machine structure.

Main technical parameters

1. Production Machine General Working Condition

Area of production line: length45m x width 3.5m x height 5m

Feeding direction: from left side to right side

Power: 380V, 50Hz, 3 phase

Pneumatic station: pressure 0-0.6MPa.,0.5m3/min.

Hydraulic oil: 46# Hydraulic oil

Gear oil: 18# gear oil

2. Unistruct Roll Forming Machine Technical parameters

Width of material sheet:≤200 mm

Thickness of material sheet: 0,95 mm up to 1,55 mm

Material of sheet:Galvanized Steel,etc

Line production speed:15-20m/min(including punching/forming/cutting)

Length of the work piece:3000mm-6000mm.

Total Power: 48.2 KW.

3. Main forming machine

Type:GY160

Forming stations:29stations(roller)

Forming machine:U channel

Forming frame:Dragon-type,gearbox drive

Max. Feeding width:≤300mm

Max. Feeding thickness:1.55mm

Roller axis:φ70 mm,shaft material:#45 quenching treatment

Material of the roller:Cr12,quenching treatment,HRC58-62°Main drive motor:22KW frequency motor drive

4. Production Line Component

Equipment part list of automatic U type auto punching/roll forming machine

| No. | Name | Type | Quant. | Power of motor (KW) |

| 1 | Passive Decoiler | MT-300 | 1 set | |

| 2 | Leveler | HS-300 | 1 set | 3 |

| 3 | Servo-feeder | NCF-300 | 1 set | 2.2 |

| 4 | JF21-80 Punching machine | YANGLI GROUP | 1 set | 7.5 |

| 5 | Punching mould | 1 set | ||

| 6 | Roll forming machine | Gantry gearbox | 1 set | 18.5X2 |

| 7 | Flying Hydraulic cutting | 1 set | 5.5 | |

| 8 | Run-out table | SL-300X4000 | 1 set | |

| 9 | Electric control system | 1 set |

5. Main Machine Technical parameter

| ,NO. | Name | unit | parameter | remark | |

1 | materials | Type | Mild steel galvanized sheet | ||

| Plate strength | ≥350 | ||||

| Plate thickness | mm | 1.5~2.5 | |||

| 2 | specification | mm | See the picture | ||

| 3 | speed | m/min | 6~8 | ||

| 4 | Material of the roller | GCr15 Hardening treatment | |||

| 5 | drive type | Gear box | |||

| 6 | power | kw | About40 | ||

| 7 | Electrical control system | PCL frequency control | |||

| 8 | Size(lengthXwidthXheight) | m | 35X4X3.9 | ||

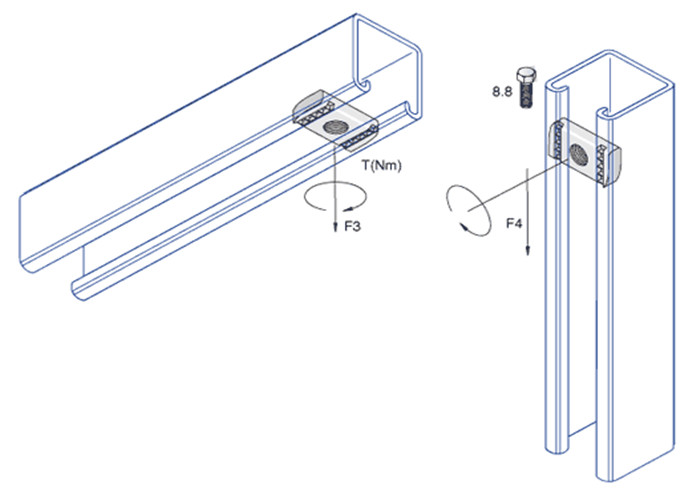

6. Unistruct Drawing or Size

7. Full line is controlled by PLC control system with touch screen operation to achieve the human and PLC interactive. The operator can monitor the setting program (programmable control) and modify the parameter to control the line. Also can check the running status, parameter and error indication etc...

Operation type: manual /auto two type switch. In manual position: can run the each part of the machine. In auto position: can run the full line. The emergency stop ensures the safe of the equipment and operator.

Machine side is equipped with the manual operation control panel for convenient worker to operate;