TOBO STEEL GROUP CHINA |

|

Verified Suppliers

|

|

| Standard: | ASTM, AISI, DIN, EN, GB, JIS | Dimensions: | 2-400mm | Grade: | 200 Series &300 Series &400 Series |

| Place of Origin: | Shanghai, China (Mainland) | Brand Name: | TOBO | Model Number: | GA-BAR |

| Type: | Round | Application: | petroleum, Foodstuff, chemical industry, construction, electric

power | Shape: | Round, flat,square,hexagon,angle,channel,threaded |

| Certification: | ISO | Product name: | stainless steel bar | Diameter: | 2-400mm |

| Length: | within 6000mm or according to the customer's requirement | Technique: | Forged/Hot Rolled/Cold Drawn/Peeled | Surface: | bright, pickled, black |

| Loading Port: | Shanghai | Delivery term: | FOB,CFR, CIF,EXW | Delivery lead time: | 7-30 working days after received deposit |

| Quality assurance: | Mill Test Certificate is supplied |

| Packaging Details: | seaworthy package or according to customer's request of stainless steel bar |

| Delivery Detail: | 7-30 days,according to the quantity of stainless steel bar |

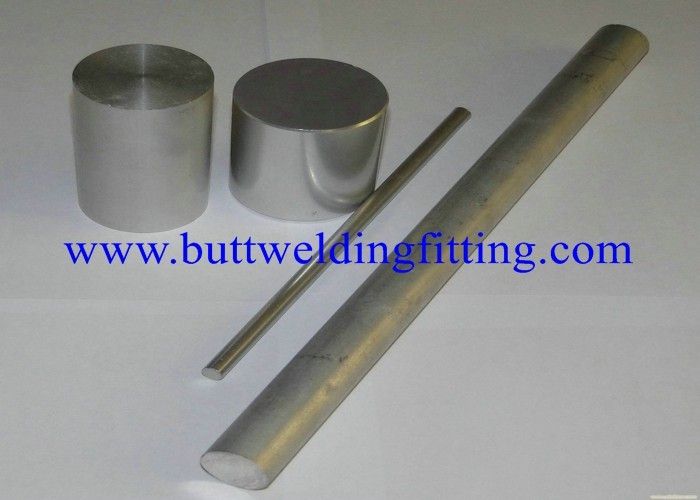

Black / Acid / Bright / Grinded ASTM A479 316L

stainless steel bar

Product Category of Stainless Steel Bar:

1. Round bar

1) Hot rolled black bar: (5-400)x6000mm or according to your requirement.

2) Acid round bar: (5-400)x6000mm or according to your requirement.

3) Cold drawn bright bar: (1-20)x6000mm or according to your requirement.

4) Polishing round bar: (5-400)x6000mm or according to your requests.

2. Square bar

1) Hot rolled black bar: (5*5-400*400)x6000mm or according to your requests.

2) Acid square bar: (5*5-400*400)x6000mm or according to your requests.

3) Cold drawn square bar: (1*1-20*20)x6000mm or according to your requests.

4) Polishing square bar: (5*5-400*400)x6000mm or according to your requests.

3. Flat bar

1) Hot rolled flat bar: (3-30)*(10-200mm)*6000mm or according to your requests.

2) Cold drawn flat bar: (3-30)*(10-200mm)*6000mm or according to your requests.

4. Hexagon bar

1) Hot rolled hexagon bar: (5-100)x6000mm or according to your requests.

2) Acid hexagon bar: (5-100)x6000mm or according to your requests.

3) Cold drawn hexagon bar: (1-20)x6000mm or according to your requests t.

4) Polishing hexagon bar: (5-100)x6000mm or according to your requests.

5. Channel bar

1) Hot rolled channel bar: (5-100)x6000mm or according to your requests.

2) Acid channel bar: (5-100)x6000mm or according to your requests.

3) Cold drawn channel bar: (1-20)x6000mm or according to your requests.

6. Angle bar

1) Hot rolled angle bar: (16-200)x(16-200)x(3-18)x(3000-9000)mm or according to your requests

2) Acid angle bar: (16-200)x(16-200)x(3-18)x(3000-9000)mm or according to your requests.

3) Cold drawn angle bar: (16-200)x(16-200)x(3-18)x(3000-9000)mm or according to your requests.

Chemical Composition:

| Chemical Requirements ASTM A276-06 | ||||||||||

| UNS | Type | Composition, % | ||||||||

| Designa- tionB | Phos- phorus | Molyb- denum | ||||||||

| Carbon | Manganese | Sulfur | Silicon | Chromium | Nickel | Nitrogen | ||||

| Austenitic Grades | ||||||||||

| S20100 | 201 | 0.15 | 5.5–7.5 | 0.06 | 0.03 | 1 | 16.0–18.0 | 3.5–5.5 | . . . | 0.25 |

| S20161 | . . . | 0.15 | 4.0–6.0 | 0.045 | 0.03 | 3.0–4.0 | 15.0–18.0 | 4.0–6.0 | . . . | 0.08–0.20 |

| S20162 | . . . | 0.15 | 4.0–8.0 | 0.04 | 0.04 | 2.5–4.5 | 16.5–21.0 | 6.0–10.0 | 0.50–2.50 | 0.05–0.25 |

| S20200 | 202 | 0.15 | 7.5–10.0 | 0.06 | 0.03 | 1 | 17.0–19.0 | 4.0–6.0 | . . . | 0.25 |

| S20500 | 205 | 0.12–0.25 | 14.0–15.5 | 0.06 | 0.03 | 1 | 16.5–18.0 | 1.0–1.7 | . . . | 0.32–0.40 |

| S20910 | XM-19 | 0.06 | 4.0–6.0 | 0.045 | 0.03 | 1 | 20.5–23.5 | 11.5–13.5 | 1.50–3.00 | 0.20–0.40 |

| S21800 | . . . | 0.1 | 7.0–9.0 | 0.06 | 0.03 | 3.5–4.5 | 16.0–18.0 | 8.0–9.0 | . . . | 0.08–0.18 |

| S21900 | XM-10 | 0.08 | 8.0–10.0 | 0.045 | 0.03 | 1 | 19.0–21.5 | 5.5–7.5 | . . . | 0.15–0.40 |

| S21904 | XM-11 | 0.04 | 8.0–10.0 | 0.045 | 0.03 | 1 | 19.0–21.5 | 5.5–7.5 | . . . | 0.15–0.40 |

| S24000 | XM-29 | 0.08 | 11.5–14.5 | 0.06 | 0.03 | 1 | 17.0–19.0 | 2.3–3.7 | . . . | 0.20–0.40 |

| S24100 | XM-28 | 0.15 | 11.0–14.0 | 0.045 | 0.03 | 1 | 16.5–19.0 | 0.50–2.50 | . . . | 0.20–0.45 |

| S28200 | . . . | 0.15 | 17.0–19.0 | 0.045 | 0.03 | 1 | 17.0–19.0 | . . . | 0.75–1.25 | 0.40–0.60 |

| S30200 | 302 | 0.15 | 2 | 0.045 | 0.03 | 1 | 17.0–19.0 | 8.0–10.0 | . . . | 0.1 |

| S30215 | 302B | 0.15 | 2 | 0.045 | 0.03 | 2.00–3.00 | 17.0–19.0 | 8.0–10.0 | . . . | 0.1 |

| S30400 | 304 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0–20.0 | 8.0–11.0 | . . . | . . . |

| S30403 | 304LC | 0.03 | 2 | 0.045 | 0.03 | 1 | 18.0–20.0 | 8.0–12.0 | . . . | . . . |

| S30451 | 304N | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0–20.0 | 8.0–11.0 | . . . | 0.10–0.16 |

| S30452 | XM-21 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0–20.0 | 8.0–10.0 | . . . | 0.16–0.30 |

| S30453 | 304LN | 0.03 | 2 | 0.045 | 0.03 | 1 | 18.0–20.0 | 8.0–11.0 | . . . | 0.10–0.16 |

| S30454 | . . . | 0.03 | 2 | 0.045 | 0.03 | 1 | 18.0–20.0 | 8.0–11.0 | . . . | 0.16–0.30 |

| S30500 | 305 | 0.12 | 2 | 0.045 | 0.03 | 1 | 17.0–19.0 | 11.0–13.0 | . . . | . . . |

| S30800 | 308 | 0.08 | 2 | 0.045 | 0.03 | 1 | 19.0–21.0 | 10.0–12.0 | . . . | . . . |

| S30815 | . . . | 0.05–0.10 | 0.8 | 0.04 | 0.03 | 1.40–2.00 | 20.0–22.0 | 10.0–12.0 | . . . | 0.14–0.20 |

| S30900 | 309 | 0.2 | 2 | 0.045 | 0.03 | 1 | 22.0–24.0 | 12.0–15.0 | . . . | . . . |

| S30908 | 309S | 0.08 | 2 | 0.045 | 0.03 | 1 | 22.0–24.0 | 12.0–15.0 | . . . | . . . |

| S30940 | 309Cb | 0.08 | 2 | 0.045 | 0.03 | 1 | 22.0–24.0 | 12.0–16.0 | . . . | . . . |

| S31000 | 310 | 0.25 | 2 | 0.045 | 0.03 | 1.5 | 24.0–26.0 | 19.0–22.0 | . . . | . . . |

| S31008 | 310S | 0.08 | 2 | 0.045 | 0.03 | 1.5 | 24.0–26.0 | 19.0–22.0 | . . . | . . . |

| S31040 | 310Cb | 0.08 | 2 | 0.045 | 0.03 | 1.5 | 24.0–26.0 | 19.0–22.0 | . . . | . . . |

| S31254 | . . . | 0.02 | 1 | 0.03 | 0.01 | 0.8 | 19.5–20.5 | 17.5–18.5 | 6.0–6.5 | 0.18–0.22 |

| S31400 | 314 | 0.25 | 2 | 0.045 | 0.03 | 1.50–3.00 | 23.0–26.0 | 19.0–22.0 | . . . | . . . |

| S31600 | 316 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0–18.0 | 10.0–14.0 | 2.00–3.00 | . . . |

| S31603 | 316LC | 0.03 | 2 | 0.045 | 0.03 | 1 | 16.0–18.0 | 10.0–14.0 | 2.00–3.00 | . . . |

| S31635 | 316Ti | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0–18.0 | 10.0–14.0 | 2.00–3.00 | 0.1 |

| S31640 | 316Cb | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0–18.0 | 10.0–14.0 | 2.00–3.00 | 0.1 |

| S31651 | 316N | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0–18.0 | 10.0–14.0 | 2.00–3.00 | 0.10–0.16 |

| S31653 | 316LN | 0.03 | 2 | 0.045 | 0.03 | 1 | 16.0–18.0 | 10.0–13.0 | 2.00–3.00 | 0.10–0.16 |

| S31654 | ... | 0.03 | 2 | 0.045 | 0.03 | 1 | 16.0–18.0 | 10.0–13.0 | 2.00–3.00 | 0.16–0.30 |

| S31700 | 317 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0–20.0 | 11.0–15.0 | 3.0–4.0 | 0.1 |

| S31725 | . . . | 0.03 | 2 | 0.045 | 0.03 | 1 | 18.0–20.0 | 13.5–17.5 | 4.0–5.0 | 0.2 |

| S31726 | . . . | 0.03 | 2 | 0.045 | 0.03 | 1 | 17.0–20.0 | 14.5–17.5 | 4.0–5.0 | 0.10–0.20 |

| S31727 | . . . | 0.03 | 1 | 0.03 | 0.03 | 1 | 17.5–19.0 | 14.5–16.5 | 3.8–4.5 | 0.15–0.21 |

| S32053 | . . . | 0.03 | 1 | 0.03 | 0.01 | 1 | 22.0–24.0 | 24.0–26.0 | 5.0–6.0 | 0.17–0.22 |

| S32100 | 321 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0–19.0 | 9.0–12.0 | . . . | . . . |

| S32654 | . . . | 0.02 | 2.0–4.0 | 0.03 | 0.005 | 0.5 | 24.0–25.0 | 21.0–23.0 | 7.0–8.0 | 0.45–0.55 |

| S34565 | . . . | 0.03 | 5.0–7.0 | 0.03 | 0.01 | 1 | 23.0–25.0 | 16.0–18.0 | 4.0–5.0 | 0.40–0.60 |

| S34700 | 347 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0–19.0 | 9.0–12.0 | . . . | . . . |

| S34800 | 348 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0–19.0 | 9.0–12.0 | . . . | . . . |

| Ferritic Grades | ||||||||||

| S40500 | 405 | 0.08 | 1 | 0.04 | 0.03 | 1 | 11.5–14.5 | 0.5 | . . . | . . . |

| S40976 | . . . | 0.03 | 1 | 0.04 | 0.03 | 1 | 10.5–11.7 | 0.75–1.00 | . . . | 0.04 |

| S42900 | 429 | 0.12 | 1 | 0.04 | 0.03 | 1 | 14.0–16.0 | . . . | . . . | . . . |

| S43000 | 430 | 0.12 | 1 | 0.04 | 0.03 | 1 | 16.0–18.0 | . . . | . . . | . . . |

| S44400 | 444 | 0.025 | 1 | 0.04 | 0.03 | 1 | 17.5–19.5 | 1 | 1.75–2.50 | 0.035 |

| S44600 | 446 | 0.2 | 1.5 | 0.04 | 0.03 | 1 | 23.0–27.0 | 0.75 | . . . | 0.25 |

| S44627 | XM-27F | 0.010G | 0.4 | 0.02 | 0.02 | 0.4 | 25.0–27.5 | 0.5 | 0.75–1.50 | 0.015G |

| S44700 | . . . | 0.01 | 0.3 | 0.025 | 0.02 | 0.2 | 28.0–30.0 | 0.15 | 3.5–4.2 | 0.02 |

| S44800 | . . . | 0.01 | 0.3 | 0.025 | 0.02 | 0.2 | 28.0–30.0 | 2.00–2.50 | 3.5–4.2 | 0.02 |

| Martensitic Grades | ||||||||||

| S40300 | 403 | 0.15 | 1 | 0.04 | 0.03 | 0.5 | 11.5–13.0 | . . . | . . . | . . . |

| S41000 | 410 | 0.08–0.15 | 1 | 0.04 | 0.03 | 1 | 11.5–13.5 | . . . | . . . | . . . |

| S41040 | XM-30 | 0.18 | 1 | 0.04 | 0.03 | 1 | 11.0–13.0 | . . . | . . . | . . . |

| S41400 | 414 | 0.15 | 1 | 0.04 | 0.03 | 1 | 11.5–13.5 | 1.25–2.50 | . . . | . . . |

| S41425 | . . . | 0.05 | 0.50–1.00 | 0.02 | 0.005 | 0.5 | 12.0–15.0 | 4.0–7.0 | 1.50–2.00 | 0.06–0.12 |

| S41500 | H | 0.05 | 0.50–1.00 | 0.03 | 0.03 | 0.6 | 11.5–14.0 | 3.5–5.5 | 0.50–1.00 | . . . |

| S42000 | 420 | 0.15 min | 1 | 0.04 | 0.03 | 1 | 12.0–14.0 | . . . | . . . | . . . |

| S42010 | . . . | 0.15–0.30 | 1 | 0.04 | 0.03 | 1 | 13.5–15.0 | 0.35–0.85 | 0.40–0.85 | . . . |

| S43100 | 431 | 0.2 | 1 | 0.04 | 0.03 | 1 | 15.0–17.0 | 1.25–2.50 | . . . | . . . |

| S44002 | 440A | 0.60–0.75 | 1 | 0.04 | 0.03 | 1 | 16.0–18.0 | . . . | 0.75 | . . . |

| S44003 | 440B | 0.75–0.95 | 1 | 0.04 | 0.03 | 1 | 16.0–18.0 | . . . | 0.75 | . . . |

| S44004 | 440C | 0.95–1.20 | 1 | 0.04 | 0.03 | 1 | 16.0–18.0 | . . . | 0.75 | . . . |

|

|

Corrosion Resistance:

Incoloy 800, like many austenitic stainless steels, can be sensitized, or made susceptible to intergranular attack in some aggressive media, by exposure to the temperature range of 1000 to 1400F.

Applications:

For services below 600 degree centigrade the use of soft annealed incoloy 800 is suggested. Incoloy 800 has

applications in furnae components and equipment, petrochemical furnace cracker tubes, pigtails,headers and

sheathing for electrical heating elements.

Packaging is one of the best service of Ronsco, in order to prevent the damage from transit, our finished products are packaged carefully. All of our stainless steel sheet products will be transported with steel pallets or wooden pallets.

Customers will be guaranteed that the product they received from

TOBO can go directly into the production and out to the

customers as finished product.