Suzhou Kiande Electric Co.,Ltd. |

|

Verified Suppliers

|

|

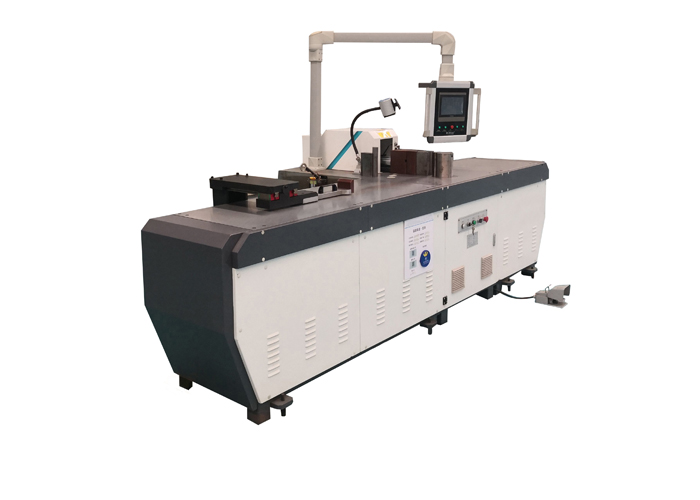

CNC Busbar Bending Machine

CNC busbar bending machine is computer-controlled special equipment

for busbar bender processing, completing all kinds of bending

actions through the mutual cooperation of X axis and Y axis

movement and manually assisted feeding. Choosing different dies can

complete the level bending, vertical bending and other machining

processes of busbars. The machine can accurately calculate the

bending length by using SH3D control drawing software . For the

workpieces large in the amount of bending, the machine can

automatically seek bending order, realizing programming automation.

The machine with a unique big closed bending structure, has not

only the excellent performance of closed bending but also the

convenience of open bending; X-axis and Y-axis adopts line guides

to guarantee the consistency in the width direction of the

processing angle; The machine has the function of compensating for

angle errors, and its bending precision can reach the

high-performance index of ±0.1°;

The machine has automatic clamping and releasing function in the

lateral bending process, and can greatly improve processing

efficiency compared with manual operation.

Technical parameters

| tems | Units | Parameters |

| Force | KN | 400 |

| Bending accuracy | degree | degree Automatic compensation < ± 0.5+Manual compensation can be up to< ± 0.2 |

| Max. stroke of bending | mm | 250 |

| Stroke of lateral block material | mm | 2000 |

| Max. moving speed of lateral block material | M/min | 35 |

| Bending head | M/min | 6 quick 12,slow 6 |

| Min. width of U-bending | HPM | 40 |

| Max. bending angle | degree | 88 |

| Level bending (WxT) | mm | 200 x 16 |

| Vertical bending (WxT) | mm | 120x 12 |

| Total weight | Kg | 2800 |

| Host area :Lx W | mm | 6000x3500 |

| Max. hydraulic pressure | Mpa | 35 |

| Total power | kw | 7.3 |