VIIPLUS INTERNATIONAL |

|

The CuZn24Al6 Self-Lubricated Brass Alloy Bushings SPB are precision-engineered components designed to provide exceptional wear resistance and lubrication properties in various industrial applications. This brass alloy bushing, with its unique composition of copper, zinc, and aluminum, offers superior mechanical properties, ensuring durability and reliability even under high loads and speeds.

The self-lubricated feature of the CuZn24Al6 alloy bushings significantly reduces the need for external lubrication, thereby simplifying maintenance procedures and cutting down on operational costs. The alloy's inherent lubricity helps minimize friction and heat generation, resulting in smoother operation and longer component lifespan.

The SPB bushings are manufactured to precise tolerances, ensuring a perfect fit and optimal performance in various applications. Whether used in automotive systems, machinery, or any other industrial equipment, the CuZn24Al6 Self-Lubricated Brass Alloy Bushings SPB offer a reliable and cost-effective solution for enhancing the wear resistance and lubrication of rotating assemblies.

Overall, the CuZn24Al6 Self-Lubricated Brass Alloy Bushings SPB are a superior choice for industrial applications that require high performance, durability, and reduced maintenance. Their unique alloy composition and precision manufacturing make them stand out as a reliable component in various industrial settings.

CuZn24AL6 Self-Lubricated Brass Alloy Bushings

Self Lubricating Brass Bushing

Bronze Graphite Bearing Sold Lubricating Bushing

High Load Capacity Self-Lubricated Brass Bushings

Anti-Wear Oilless Bushing SPF with Excellent Performance

Product Description

Self-lubricated Brass Alloy Bushings SPB

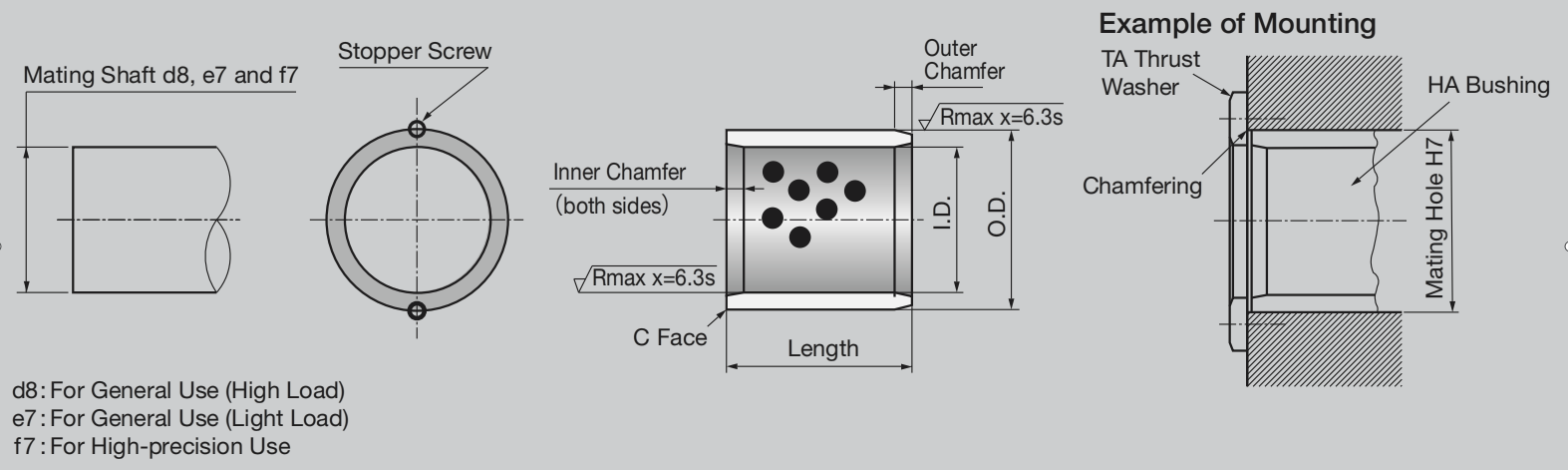

Brass alloy with embedded solid lubricant bushing is to open cavities of appropriate size and orderly arrangement on the metal friction surface of the bushing matrix. It was embedded a molded solid lubricant with unique self-lubricating properties in the cavities (the solid lubricant area is generally 25% -35% of the friction area) and made of self-lubricating bushings.

It has been used in metallurgy of continuous casting machine, rolling equipment, mining machinery, shipbuilding, gas turbines and other high temperature, high load, low speed heavy load and other occasions.

ITEM NO=SPB-XX XX XX

ID OD Length

Inquiry

| Shaft diameter | Dimension (mm) | Length (Tolerance | ID | OD | Mating washer SPW | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | 8 | 10 | 12 | 15 | 16 | 20 | 25 | 30 | 35 | 40 | 50 | 60 | 70 | 80 | 100 | 120 | 130 | 140 | 150 | ||||||

| Ød | TOL | ØD | TOL | SPB | SPB | SPB | SPB | SPB | SPB | SPB | SPB | SPB | SPB | SPB | SPB | SPB | SPB | SPB | SPB | SPB | SPB | SPB | ||||

| 8 | 8 | +0.028 | 12 | +0.018 | -0.81208 | -081210 | -081212 | -081215 | 8 | 12 | ------ | |||||||||||||||

| +0.013 | +0.007 | |||||||||||||||||||||||||

| 10 | 10 | 14 | -101408 | -101410 | -101412 | -101415 | -101420 | 10 | 14 | -1003 | ||||||||||||||||

| 12 | 12 | +0.034 | 18 | -121808 | -121810 | -121812 | -121815 | -121816 | -121820 | -121825 | -121830 | 12 | 18 | -1203 | ||||||||||||

| +0.016 | ||||||||||||||||||||||||||

| 13 | 13 | 19 | +0.021 | -131910 | -131912 | -131915 | -131920 | 13 | 19 | -1303 | ||||||||||||||||

| +0.008 | ||||||||||||||||||||||||||

| 14 | 14 | 20 | -142010 | -142012 | -142015 | -142020 | -142025 | -142030 | 14 | 20 | -1403 | |||||||||||||||

| 15 | 15 | 21 | -152110 | -152112 | -152115 | -152116 | -152120 | -152125 | -152130 | 15 | 21 | -1503 | ||||||||||||||

| 16 | 16 | 22 | -162210 | -162212 | -162215 | -162216 | -162220 | -162225 | -162230 | -162235 | -162240 | 16 | 22 | -1603 | ||||||||||||

| 18 | 18 | 24 | -182412 | -182415 | -182416 | -182420 | -182425 | -182430 | 18 | 24 | -1803 | |||||||||||||||

| 20 | 20 | +0.041 | 28 | -202810 | -202812 | -202815 | -202816 | -202820 | -202825 | -202830 | -202835 | -202840 | -202850 | 20 | 28 | -2005 | ||||||||||

| +0.02 | ||||||||||||||||||||||||||

| 20 | 30 | -203016 | -203020 | -203025 | -203030 | -203035 | -203040 | 20 | 30 | " | ||||||||||||||||

| 25 | 25 | 33 | +0.025 | -253312 | -253315 | -253316 | -253320 | -253325 | -253330 | -253335 | -253340 | -253350 | -253360 | 25 | 33 | -2505 | ||||||||||

| +0.009 | ||||||||||||||||||||||||||

| 25 | 35 | -253512 | -253515 | -253516 | -253520 | -253525 | -253530 | -253535 | -253540 | -253550 | 25 | 35 | " | |||||||||||||

| 30 | 30 | 38 | -303812 | -303815 | -303820 | -303825 | -303830 | -303835 | -303840 | -303850 | -303860 | 30 | 38 | -3005 | ||||||||||||

| 30 | 40 | -304012 | -304015 | -304020 | -304025 | -304030 | -304035 | -304040 | -304050 | -304060 | 30 | 40 | " | |||||||||||||

| 31.5 | 31.5 | +0.05 | 40 | -314030 | -314040 | 31.5 | 40 | ------ | ||||||||||||||||||

| +0.025 | ||||||||||||||||||||||||||

| 35 | 35 | 44 | -354425 | -354430 | -354435 | -354440 | -354450 | -354460 | 35 | 44 | -3505 | |||||||||||||||

| 35 | 45 | -354520 | -354525 | -354530 | -354535 | -354540 | -354550 | -354560 | 35 | 45 | " | |||||||||||||||

| 40 | 40 | 50 | -405015 | -405020 | -405025 | -405030 | -405035 | -405040 | -405050 | -405060 | -405070 | -405080 | 40 | 50 | -4007 | |||||||||||

| 40 | 55 | +0.03 | -405530 | -405535 | -405540 | -405550 | -405560 | 40 | 55 | " | ||||||||||||||||

| +0.011 | ||||||||||||||||||||||||||

| 45 | 45 | 55 | -455530 | -455535 | -455540 | -455550 | -455560 | 45 | 55 | -4507 | ||||||||||||||||

| 45 | 56 | -455630 | -455635 | -455640 | -455650 | -455660 | 45 | 56 | " | |||||||||||||||||

| 45 | 60 | -456030 | -456035 | -456040 | -456050 | -456060 | -456070 | -456080 | 45 | 60 | " | |||||||||||||||

| 50 | 50 | 60 | -506020 | -506030 | -506035 | -506040 | -506050 | -506060 | -506070 | -506080 | 50 | 60 | -5008 | |||||||||||||

| 50 | 62 | -506230 | -506235 | -506240 | -506250 | -506260 | -506270 | 50 | 62 | " | ||||||||||||||||

| 50 | 65 | -506530 | -506540 | -506550 | -506560 | -506570 | -506580 | -5065100 | 50 | 65 | " | |||||||||||||||

| 55 | 55 | +0.06 | 70 | -557030 | -557035 | -557040 | -557050 | -557060 | -557070 | 55 | 70 | -5508 | ||||||||||||||

| +0.03 | ||||||||||||||||||||||||||

| 60 | 60 | 74 | -607430 | -607435 | -607440 | -607450 | -607460 | -607470 | -607480 | 60 | 74 | -6008 | ||||||||||||||

| 60 | 75 | -607530 | -607535 | -607540 | -607550 | -607560 | -607570 | -607580 | -6075100 | 60 | 75 | " | ||||||||||||||

| 63 | 63 | 75 | -637560 | -637570 | -637580 | 63 | 75 | ------ | ||||||||||||||||||

| 65 | 65 | 80 | -658040 | -658050 | -658060 | -658070 | -658080 | 65 | 80 | -6508 | ||||||||||||||||

| 70 | 70 | 85 | +0.035 | -708530 | -708535 | -708540 | -708550 | -708560 | -708570 | -708580 | -7085100 | 70 | 85 | -7010 | ||||||||||||

| +0.013 | ||||||||||||||||||||||||||

| 70 | 90 | -709050 | -709060 | -709070 | -709080 | 70 | 90 | " | ||||||||||||||||||

| 75 | 75 | 90 | -759050 | -759060 | -759070 | -759080 | -7090100 | 75 | 90 | -7510 | ||||||||||||||||

| 75 | 95 | -759560 | -759570 | -759580 | -7595100 | 75 | 95 | " | ||||||||||||||||||

| 80 | 80 | 96 | -809640 | -809650 | -809660 | -809670 | -809680 | -8096100 | -8096120 | 80 | 96 | -8010 | ||||||||||||||

| 80 | 100 | -8010040 | -8010050 | -8010060 | -8010070 | -8010080 | -80100100 | -80100120 | -80100140 | 80 | 100 | " | ||||||||||||||

| 90 | 90 | +0.071 | 110 | -9011050 | -9011060 | -9011080 | -90110100 | -90110120 | 90 | 110 | -9010 | |||||||||||||||

| +0.036 | ||||||||||||||||||||||||||

| 100 | 100 | 120 | -10012050 | -10012060 | -10012070 | -10012080 | -100120100 | -100120120 | -100120140 | 100 | 120 | -10010 | ||||||||||||||

| 110 | 110 | 130 | +0.04 | -11013050 | -11013070 | -11013080 | -110130100 | -110130120 | 110 | 130 | ------ | |||||||||||||||

| +0.015 | ||||||||||||||||||||||||||

| 120 | 120 | 140 | -12014070 | -12014080 | -120140100 | -120140120 | -120140140 | 120 | 140 | -12010 | ||||||||||||||||

| 125 | 125 | +0.083 | 145 | -125140100 | -125145120 | 125 | 145 | ------ | ||||||||||||||||||

| +0.043 | ||||||||||||||||||||||||||

| 130 | 130 | 150 | -13015080 | -130150100 | -130150130 | 130 | 150 | ------ | ||||||||||||||||||

| 140 | 140 | 160 | -140160100 | -140160140 | 140 | 160 | ------ | |||||||||||||||||||

| 150 | 150 | 170 | -15017080 | -150170100 | -150170150 | 150 | 170 | ------ | ||||||||||||||||||

| 160 | 160 | 180 | -16018080 | -160180100 | -160180150 | 160 | 180 | ------ | ||||||||||||||||||

Cast Bronze C93200 Sleeve (Plain) Bearings Online Sale

Alloy materials

| Model | JDB-1 | JDB-2 | JDB-3 | JDB-4 | JDB-5 | ||

|---|---|---|---|---|---|---|---|

| Grade China Brands GB1776-87 | ZCuZn25 AI6Fe3Mn3 | ZCuSn6Zn6Pb3 | ZCuAI10Fe3 | ZCuSu10P1 | Steel+ZCuSn6Zn6Pb3 | HT250 | GCr15 |

| International ISO1338 | GCuZn25 AI6Fe3Mn3 | GCuSn6Zn6Pb3 | GCuAI10Fe3 | CuSn12 | Steel+CuSn6Zn6Pb3Fe3Ni5 | - | B1 |

| Germany DIN | G-CuZn25 AI5 | GB-CuSn5Zn5Pb5 | GB-CuAI10Ni | GB-CuSn10 | Steel+CuSn6Zn6Pb3Ni | - | 100Cr6 |

| Japanese JIS | HBsC4 | BC6 | AIBC3 | BC3 | BC6 | FC250 | SUJ2 |

| United States ASTM/UNS | C86300 | C83600 | C95500 | C90800 | C83600 | Class40 | 52100 |

| British Standard | HTB2 | LG2 | AB1 | PB4 | LG2 | - | - |

Material alloy chemical composition

| Chemical Elements | JDB-1 | JDB-2 | JDB-3 | JDB-4 | JDB-5 | ||

|---|---|---|---|---|---|---|---|

| Cu ( % ) | Rest | Rest | Rest | - | - | ||

| Sn ( % ) | - | 6 | - | 10 | 6 | - | - |

| Zn ( % ) | 25 | 6 | - | - | 6 | - | - |

| Ni ( % ) | - | - | - | - | - | - | - |

| AI ( % ) | 6 | - | 10 | - | - | - | - |

| Fe ( % ) | 3 | - | 3 | - | - | Rest | Rest |

| Mn ( % ) | 3 | - | - | - | - | 0.905 - 1.3 | 0.20 - 0.40 |

| Cr ( % ) | - | - | - | - | - | - | 1.30 - 1.65 |

| C ( % ) | - | - | - | - | - | 2.5 - 4 | 0.95 - 1.05 |

| Si ( % ) | - | - | - | - | - | 1.0 - 1.3 | 0.15 -0.35 |

| Pb ( % ) | - | 3 | - | - | 3 | - | - |

Technical Parameters

| Performance | JDB-1 | JDB-2 | JDB-3 | JDB-4 | JDB-5 | ||

|---|---|---|---|---|---|---|---|

| Max.load P ( N/mm² ) | 100 | 60 | 70 | 60 | 250 | ||

| Max.speed V ( m/s ) | Dry0.4 oil5 | 2 | 2 | 0.5 | 0.1 | ||

| Max.PV ( N/mm²·m/s ) | 3.8 | 0.5 | 0.6 | 0.8 | 2.5 | ||

| Density ρ( g/cmsup3 ) | 8.0 | 8.0 | 7.6 | 7.3 | 7.8 | ||

| Tensile strength ( N/mm² ) | > 600 | > 250 | > 500 | > 250 | > 1500 | ||

| Elongation ( % ) | > 10 | > 4 | > 10 | - | - | ||

| Hardness ( HB ) | > 210 | > 80 | > 80 | > 160 | HRC> 55 | ||

| Max.temp ( ℃ ) | 300 | 350 | 300 | 400 | 350 | ||

| Friction coef. ( μ ) | Oil lubrication: 0.03 | Friction(dry): 0.16 | |||||

The standard graphite plugged bronze sleeve bushing is to open cavities of appropriate size and orderly arrangement on the metal friction surface of the bearing matrix, and then embed a molded solid lubricant with unique self-lubricating properties in the cavities (the solid lubricant area is generally 25% of the friction area -35%) and made of self-lubricating bearings.

The base body of the standard graphite plugged bronze sleeve bushing should be determined according to the working conditions of the bearing itself. The more commonly used materials are high-strength brass, tin bronze, castings and so on. There are two main types of embedded solid lubricating materials, one is natural black lead, artificial graphite, and MoS2 synthesis, and the other is synthesized with PTFE as the matrix. According to the bearing's own operating conditions, the combination of different metal substrates and embedded solid lubricants can ensure that the product can meet the special needs of various temperature, load, motion and media operating conditions, while ensuring stable and reliable operation.

| Solid Lubricant | ||

| Lubricant | Features | Typical application |

| SL1 Graphite+add | Excellent resistance against chemical attacks and low friction.Temp limit 400 ℃ | Suite for general machines and under atmosphere |

| SL4 PTFE+Additives | Lowest in friction and the good of water lubrication, Temp. limit 300℃ | The ship, hydraulic turbine,gas turbine etc |

The oilless bushing, integrated into solid lubricants without oil, is a new type of solid copper alloy, which is homogeneously integrated with a solid lubricant in its body.

It breaks the limit of the general bearing, the lubrication of which depends on the oil film.

So it is suitable for high temperatures, heavy use, corrosion protection, or when oil is difficult to import.

Its performance doubles on both hardness and wear-friction.

Now it is widely applied in successive casting machines, steel rollers in metallography, mineral machines, ships, steam turbines, hydraulic turbines, and plastic injection molding machines.

Oilless Flange Sleeve Bearing Bushing, JDB material is made of

strong cast bronze based metal with special solid lubricants

embedded. The base metal with stands high load and the solid

lubricants provide for self-lubrication. Oilless Flange Sleeve

Bearing Bushing shows excellent performance without pre-lubrication

under conditions of extreme high/lower temperature with low speed.

This material provides a maintenance-free bearing solution,

particularly for high load, intermittent of oscillating motion.

Oilless Flange Sleeve Bearing Bushing can be applied under dry,

high temperature, high pressure, corrosive, water or other chemical

environments when no oil can be introduced.

Oilless Flange Sleeve Bearing Bushing is widely be used in

automotive product line, water engineering, dam gate, plastic

industries, successive casting machines, steel rollers in

metallurgy industry, mineral machines, ship turbo generators,

hydraulic turbines and injection molding machines.

Oilless Bushing - Select, configure, order. Viiplus delivers punctually and offers fair prices.

Our oilless bushings are the perfect solution for projects where lubrication cannot easily be provided or where conventional lubricants may carbonise.

Contact Us - Oilless Bushing Supplier

To make an inquiry about or request for a catalog of oilless

bushings bearings, contact today!

(Bronze with graphite embedded)

A oilless bushing, or more commonly sliding bearing and slide bearing, is the simplest type of bearing, comprising just a bearing surface and no rolling elements.

Oilless bushing can refer to ball bearings or just "rings" that do not require periodic lubrication - because a lubricant such as powdered graphite is incorporated into the material the bearing is made of. These are also known as Embedded Graphite Bronze Bushes and have 20-25% graphite inserts on the walls / surface which provide lubrication at all times which also reduces the coefficient of friction.

These oilless bushings are suitable for dry environments where contamination is a risk, wet applications where there is high humidity and applications where the bearing is in an inaccessible location.

We are leading manufacturer and supplier of Oilless Bushing and our product is made up of good quality.

The oilless bronze bushing is a new type made of a strong copper alloy and is embedded uniformly in its solid lubricant housing.

Oilless Bushes are suitable for high temperatures, heavy loads, corrosion or places where oil is difficult to introduce.

Specify Part No. by required I.D., O.D., and Length. (e.g.) I.D. is 50mm, O.D. is 62mm, and length is 50mm.

-Oilless Bronze Bushings - Copper Alloy Straight, Standard

Material: High Tensile Brass Alloy

Solid Lubricant Embedded

●Oilless bushing serviceable without the need for lubrication.

●Oilless bushing Demonstrates high performance under high-load and low-speed operations.

●Oilless bushing Demonstrates superior wear resistance in applications where oil film is seldom produced such as reciprocating motions, oscillation, frequent starts, and stops, etc.

●Oilless bushing has superior chemical resistance and corrosion resistance.

●Standard Oilless bushings products are available in various sizes.

| Density | 8.2g/cm3 | |

| Tensile Strength | >=755N/mm2 | |

| Anti-compact Tenacity | >=400~500KJ/m3 | |

| Hardness | >=200HB | |

| Max Load Pressure | 100N/mm2 | |

| Speed Limit | 0.5m/s | |

| PV value limit | 1.65N/mm2.m/s | |

| Friction coef | Oil Lubrication | 0.03 |

| Dry Friction | 0.16 | |

| Working temperature | -40~+300°C |

Please check the type/dimensions/specifications in the Oil-Free Bushings - Graphite Bronze Bushing Products - Copper Alloy Straight, Standard series.

| Oilless Bushing Type | Straight | Metal Type | High-Tensile Brass Alloy |

| Inner Dia. d(Ø) | 50 | Outer Dia. D(Ø) | 62 |

| Overall Length L(mm) | 50 | Max. Allowable PV Value Range(N/mm2•m/s) | 1.1~2.0 |

| Max. Allowable PV Value(N/mm2•m/s) | 1.16 | Maximum Allowable Load(N/mm2) | 20.3 |

| Maximum Allowable Velocity(m/s) | 0.35 | Mounting Hole Fits | H7 |

| Operating Temperature Range(°C) | -40~150 | Operating Temperature Range (Unlubricated) Min | -40 |

| Operating Temperature Range (Unlubricated) Max | 150 | Operating Temperature Range (Regular) Min | -40 |

| Operating Temperature Range (Regular) Max | 200 | - | - |

| Lubrication condition | Dry | periodic lubrication |

| Service temperature range ℃ | -40~+300 | -40~+150 |

| Allowable max. pressure P N/mm{2 kgf/cm2} | 29(150){296(1,530)} | |

| Allowable max. velocity V m/{s m/min} | 0.50{30} | 1.00{60} |

| Allowable max. PV value N/mm2・m/{s kgf/cm2・m/min} | 1.65{1,010} | 3.25{1,990} |

*The values in parentheses are static bearing pressures, which are

the bearing pressures in applications with no motion or very small

motion (≦0.0017m/s[0.1m/min]).

I.D. | O.D. | Length |

class 7 to 8 | class 6 to 7 | class 8 to 9 |

Classes here are in the JIS standard. This product demonstrates satisfactory performance at the slide surface roughness of Rz6.3 to 12.5μm.

●Applicable to the rotation, oscillation, and reciprocating motion.

●Do not use this underwater.

●63mm I.D bushing can be used as an intermediate trunnion

bushing for hydraulic cylinders.

| Model | JDB-1 | JDB-2 | JDB-3 | JDB-4 | JDB-5 | ||

| Grade China Brands GB1776-87 | ZCuZn25 AI6Fe3Mn3 | ZCuSn6Zn6Pb3 | ZCuAI10Fe3 | ZCuSu10P1 | Steel+ZCuSn6Zn6Pb3 | HT250 | GCr15 |

| International ISO1338 | GCuZn25 AI6Fe3Mn3 | GCuSn6Zn6Pb3 | GCuAI10Fe3 | CuSn12 | Steel+CuSn6Zn6Pb3Fe3Ni5 | - | B1 |

| Germany DIN | G-CuZn25 AI5 | GB-CuSn5Zn5Pb5 | GB-CuAI10Ni | GB-CuSn10 | Steel+CuSn6Zn6Pb3Ni | - | 100Cr6 |

| Japanese JIS | HBsC4 | BC6 | AIBC3 | BC3 | BC6 | FC250 | SUJ2 |

| United States ASTM/UNS | C86300 | C83600 | C95500 | C90800 | C83600 | Class40 | 52100 |

| British Standard | HTB2 | LG2 | AB1 | PB4 | LG2 | - | - |

| Chemical Elements | JDB-1 | JDB-2 | JDB-3 | JDB-4 | JDB-5 | ||

| Cu ( % ) | Rest | Rest | Rest | - | - | ||

| Sn ( % ) | - | 6 | - | 10 | 6 | - | - |

| Zn ( % ) | 25 | 6 | - | - | 6 | - | - |

| Ni ( % ) | - | - | - | - | - | - | - |

| AI ( % ) | 6 | - | 10 | - | - | - | - |

| Fe ( % ) | 3 | - | 3 | - | - | Rest | Rest |

| Mn ( % ) | 3 | - | - | - | - | 0.905 - 1.3 | 0.20 - 0.40 |

| Cr ( % ) | - | - | - | - | - | - | 1.30 - 1.65 |

| C ( % ) | - | - | - | - | - | 2.5 - 4 | 0.95 - 1.05 |

| Si ( % ) | - | - | - | - | - | 1.0 - 1.3 | 0.15 -0.35 |

| Pb ( % ) | - | 3 | - | - | 3 | - | - |

| Performance | JDB-1 | JDB-2 | JDB-3 | JDB-4 | JDB-5 |

| Max.load P ( N/mm² ) | 100 | 60 | 70 | 60 | 250 |

| Max.speed V ( m/s ) | Dry0.4 oil5 | 2 | 2 | 0.5 | 0.1 |

| Max.PV ( N/mm²·m/s ) | 3.8 | 0.5 | 0.6 | 0.8 | 2.5 |

| Density ρ( g/cmsup3 ) | 8.0 | 8.0 | 7.6 | 7.3 | 7.8 |

| Tensile strength ( N/mm² ) | > 600 | > 250 | > 500 | > 250 | > 1500 |

| Elongation ( % ) | > 10 | > 4 | > 10 | - | - |

| Hardness ( HB ) | > 210 | > 80 | > 80 | > 160 | HRC> 55 |

| Max.temp ( ℃ ) | 300 | 350 | 300 | 400 | 350 |

| Friction coef. ( μ ) | Oil lubrication: 0.03 | Friction(dry): 0.16 | |||

| I.D. | O.D. | Length L Tolerance -0.1 -0.3 | |||||||||

| φd | Tolerance | φD | Tolerance | 8 | 10 | 12 | 15 | 16 | 19 | 20 | 25 |

| 6 | +0.022 +0.010 | 10 | +0.015 +0.006 | 061008 | 061010 | 061012 | |||||

| 8 | +0.028 +0.013 | 12 | +0.018 +0.007 | 081208 | 081210 | 081212 | 081215 | ||||

| 10 | +0.028 +0.013 | 14 | +0.018 +0.007 | 101408 | 101410 | 101412 | 101415 | 101420 | |||

| 12 | +0.034 +0.016 | 18 | +0.018 +0.007 | 121808 | 121810 | 121812 | 121815 | 121816 | 121819 | 121820 | 121825 |

| 13 | +0.034 +0.016 | 19 | +0.021 +0.008 | 131910 | 131912 | 131915 | 131920 | 131925 | |||

| 14 | +0.034 +0.016 | 20 | +0.021 +0.008 | 142010 | 142012 | 142015 | 142020 | 142025 | |||

| 15 | +0.034 +0.016 | 21 | +0.021 +0.008 | 152110 | 152112 | 152115 | 152116 | 152120 | 152125 | ||

| 16 | +0.034 +0.016 | 22 | +0.021 +0.008 | 162210 | 162212 | 162215 | 162216 | 162219 | 162220 | 162225 | |

| 17 | +0.034 +0.016 | 23 | +0.021 +0.008 | 172315 | |||||||

| 18 | +0.034 +0.016 | 24 | +0.021 +0.008 | 182410 | 182412 | 182415 | 182416 | 182420 | 182425 | ||

| 19 | +0.041 +0.020 | 26 | +0.021 +0.008 | 192615 | 192620 | ||||||

| 20 | +0.041 +0.020 | 28 | +0.021 +0.008 | 202810 | 202812 | 202815 | 202816 | 202819 | 202820 | 202825 | |

| 20 | +0.041 +0.020 | 30 | +0.021 +0.008 | 203010 | 203012 | 203015 | 203016 | 203020 | 203025 | ||

| 22 | +0.041 +0.020 | 32 | +0.025 +0.009 | 223212 | 223215 | 223220 | 223225 | ||||

| 25 | +0.041 +0.020 | 33 | +0.025 +0.009 | 253312 | 253315 | 253316 | 253320 | 253325 | |||

| 25 | +0.041 +0.020 | 35 | +0.025 +0.009 | 253512 | 253515 | 253516 | 253520 | 253525 | |||

| 28 | +0.041 +0.020 | 38 | +0.025 +0.009 | 283820 | 283825 | ||||||

| 30 | +0.041 +0.020 | 38 | +0.025 +0.009 | 303812 | 303815 | 303820 | 303825 | ||||

| 30 | +0.041 +0.020 | 40 | +0.025 +0.009 | 304012 | 304015 | 304020 | 304025 | ||||

| 31.5 | +0.050 +0.025 | 40 | +0.025 +0.009 | ||||||||

| 32 | +0.050 +0.025 | 42 | +0.025 +0.009 | 324220 | |||||||

| 35 | +0.050 +0.025 | 44 | +0.025 +0.009 | 354420 | 354425 | ||||||

| 35 | +0.050 +0.025 | 45 | +0.025 +0.009 | 354520 | 354525 | ||||||

| 38 | +0.050 +0.025 | 48 | +0.025 +0.009 | ||||||||

| 40 | +0.050 +0.025 | 50 | +0.025 +0.009 | 405015 | 405020 | 405025 | |||||

| 40 | +0.050 +0.025 | 55 | +0.030 +0.011 | 405515 | |||||||

| 45 | +0.050 +0.025 | 55 | +0.030 +0.011 | ||||||||

| 45 | +0.050 +0.025 | 56 | +0.030 +0.011 | ||||||||

| 45 | +0.050 +0.025 | 60 | +0.030 +0.011 | ||||||||

*The I.D. tolerance after press fitting is for reference only.

| I.D. | O.D. | Length L Tolerance -0.1 -0.3 | |||||||||

| φd | Tolerance | φD | Tolerance | 20 | 30 | 35 | 40 | 50 | 60 | 70 | 80 |

| 50 | +0.050 +0.025 | 60 | +0.030 +0.011 | 506020 | 506030 | 506035 | 506040 | 506050 | 506060 | 506070 | 506080 |

| 50 | +0.050 +0.025 | 62 | +0.030 +0.011 | 506230 | 506235 | 506240 | 506250 | 506260 | 506270 | 506280 | |

| 50 | +0.050 +0.025 | 65 | +0.030 +0.011 | 506530 | 506540 | 506550 | 506560 | 506570 | 506580 | ||

| 55 | +0.060 +0.030 | 70 | +0.030 +0.011 | 557030 | 557035 | 557040 | 557050 | 557060 | 557070 | ||

| 60 | +0.060 +0.030 | 74 | +0.030 +0.011 | 607430 | 607435 | 607440 | 607450 | 607460 | 607470 | 607480 | |

| 60 | +0.060 +0.030 | 75 | +0.030 +0.011 | 607530 | 607535 | 607540 | 607550 | 607560 | 607570 | 607580 | |

| 63 | +0.060 +0.030 | 75 | +0.030 +0.011 | 637560 | 637570 | 637580 | |||||

| 65 | +0.060 +0.030 | 80 | +0.030 +0.011 | 658040 | 658050 | 658060 | 658070 | 658080 | |||

| 70 | +0.060 +0.030 | 85 | +0.035 +0.013 | 708530 | 708535 | 708540 | 708550 | 708560 | 708570 | 708580 | |

| 70 | +0.060 +0.030 | 90 | +0.035 +0.013 | 709050 | 709060 | 709070 | 709080 | ||||

| 75 | +0.060 +0.030 | 90 | +0.035 +0.013 | 759050 | 759060 | 759070 | 759080 | ||||

| 75 | +0.060 +0.030 | 95 | +0.035 +0.013 | 759560 | 759570 | 759580 | |||||

| 80 | +0.060 +0.030 | 96 | +0.035 +0.013 | 809640 | 809650 | 809660 | 809670 | 809680 | |||

| 80 | +0.060 +0.030 | 100 | +0.035 +0.013 | 8010040 | 8010050 | 8010060 | 8010070 | 8010080 | |||

| 85 | +0.071 +0.036 | 100 | +0.035 +0.013 | 8510060 | 8510080 | ||||||

| 90 | +0.071 +0.036 | 110 | +0.035 +0.013 | 9011050 | 9011060 | 9011080 | |||||

| 100 | +0.071 +0.036 | 120 | +0.035 +0.013 | 10012050 | 10012060 | 10012070 | 10012080 | ||||

| 110 | +0.071 +0.036 | 130 | +0.040 +0.015 | 11013050 | 11013070 | 11013080 | |||||

| 120 | +0.071 +0.036 | 140 | +0.040 +0.015 | 12014070 | 12014080 | ||||||

| 125 | +0.083 +0.043 | 145 | +0.040 +0.015 | ||||||||

| 130 | +0.083 +0.043 | 150 | +0.040 +0.015 | 13015080 | |||||||

| 140 | +0.083 +0.043 | 160 | +0.040 +0.015 | ||||||||

| 150 | +0.083 +0.043 | 170 | +0.040 +0.015 | 15017080 | |||||||

| 160 | +0.083 +0.043 | 180 | +0.040 +0.015 | 16018080 | |||||||

| 170 | +0.083 +0.043 | 190 | +0.046 +0.017 | ||||||||

| 180 | +0.083 +0.043 | 200 | +0.046 +0.017 | ||||||||

| 190 | +0.096 +0.050 | 210 | +0.046 +0.017 | ||||||||

| 200 | +0.096 +0.050 | 230 | +0.046 +0.017 | ||||||||

*The dimensional tolerances are the values measured at +25℃.

Metric oilless bushing and imperial oilless bronze bushing made to order: standard bushing forms in special dimensions, half-bushings, special shapes obtained by stamping or deep drawing, customized bushing designs

The product is widely used in continuous casting rolling machine,

mining machinery, shipping machinery, turbine, injection machinery,

auto mould

and so on.

1. Oilless bush use for high load low speed and self-lub. like dam

gate and water gate bushes, hydraulic turbine bushes etc.

2. Oilless bushing use for high temp. such as iron and steel

factory machines and so on.

3. Oilless graphite bronze bushing use for Automobile production,

like assembly lines, press lines, conveyor lines and so on.

4. Oilless bronze bushing use for heavy duty machineries like steel

rolling mills, injection machines, press dies etc.

5. Oilless bushes also use for chemical machines, food processing

machines, paper mills, textile machines etc.

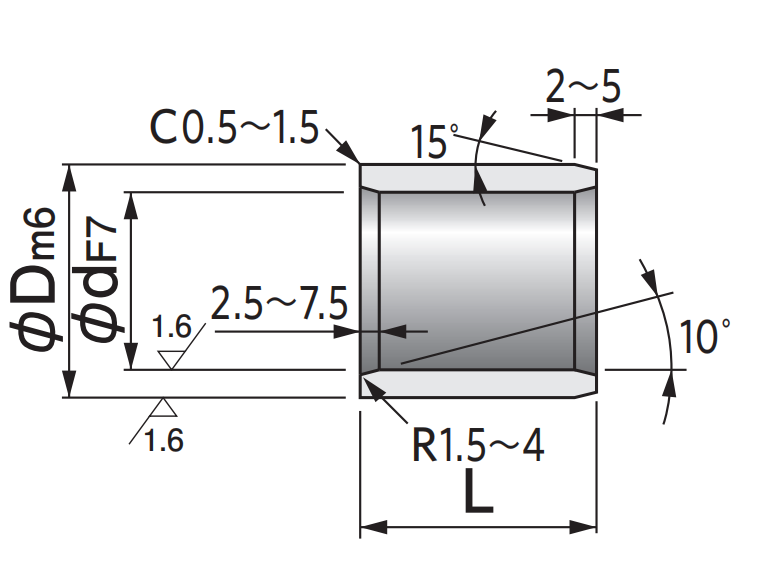

● Oilless bushes for toggle link

1. Guide Bushes

2. Ejector Guide Bushes

3. Guide Rail

4. Guide Block

5. Lower Plate

6. Guide Bushes

7. Formwork Bushes

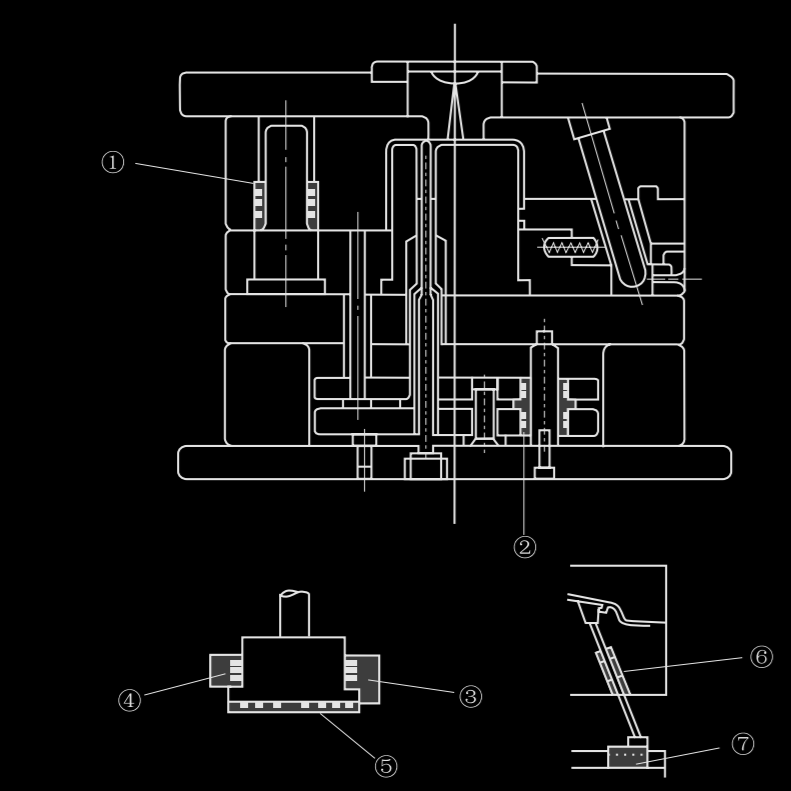

1. Wear Plate

2. Cam Stroke Plate

3. Cam Upper Plate

4. Cam Side Block

5. Cam Side Plate

6. Cam Positive Return Plate

7. Guide Post Bushes

8. Cam Stroke Plate

Viiplus Oilless Bronze Bushing Used In Many Application

Whatever the bronze oilless bushing material & specification, whatever the oilless bush standard shape or size, if it's physically possible, we can make it.

Viiplus is one of the most experienced oilless bushing suppliers, if you want to download the oilless bush catalogue, Contact Us Now!