VIIPLUS INTERNATIONAL |

|

The tin-plated POM composite SF-2 bronze bearing thrust washer is an innovative component designed for oil-free operation. Constructed from a combination of POM (polyoxymethylene) and bronze, this thrust washer offers exceptional durability and wear resistance.

The tin plating on the surface of the POM composite enhances its corrosion resistance, ensuring longer service life even in harsh environments. The bronze material, known for its excellent mechanical properties, provides a strong and stable base for the thrust washer.

The SF-2 design of this bearing thrust washer is optimized for high-load applications, making it suitable for a wide range of industrial uses. The oilless design eliminates the need for lubrication, reducing maintenance requirements and operational costs.

The precision engineering of this thrust washer ensures a smooth and reliable operation, minimizing friction and wear. This results in improved efficiency and reduced downtime, enhancing the overall performance of the machinery it is installed in.

Whether you are upgrading an existing system or designing a new one, the tin-plated POM composite SF-2 bronze bearing thrust washer is an excellent choice for achieving reliable and efficient thrust transmission. Its oilless design makes it a cost-effective and environmentally friendly solution for various industrial applications.

SF-2 Marginal Lbricating Bearing is used steel-backing as its structure, sintered porous bronze as its interlayer, surface inlaid the modified POM.

Suitable for marginally lubricated and dry operation on the conditions of lubrication indents grease.

It has been widely applied to metallurgical machinery, Mine machinery, water conservancy machinery, vapor locomotive, building machinery, agriculture machinery, steel rolling industry etc.

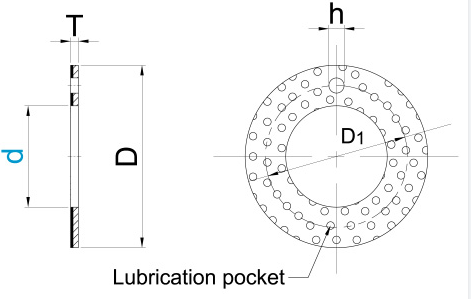

POM composite thrust washers have pockets in the sliding surface, which serve as grease reservoirs and should be filled with grease prior to installation. This makes these washers suitable for applications that require minimal maintenance under difficult operating conditions, for example in contaminated environments where lubricant cannot be supplied continuously or frequently. Despite of their compact design, POM composite washers can accommodate heavy axial loads and are less sensitive to misalignment. They are suitable for slow rotational or oscillating movements.

POM composite thrust washers consists of a sheet steel backing on which a 0,2 to 0,4 mm thick layer of tin/bronze is sintered. The principal characteristic of these washers is their relatively thick (0,3 mm) covering layer of acetal resin (POM – polyoxymethylene) with additives. This covering layer has pockets to retain grease and is firmly attached to the sintered tin/bronze layer.

The thickness of the covering layer makes these washers less sensitive to misalignment and the edge loading associated with that misalignment.

| Brand | Viiplus | |

| Base material | Steel/Bronze | |

| Maximum temperaturet | -40°C-300°C | |

| Max Load Capacity P | 70-250N/mm² | |

| Coefficient of friction u | 0.05-0.20u | |

| Material Organization | 1. POM with fiber 0.3 ~ 0.5mm | |

| 2. Porous bronze 0.2 ~ 0.3mm | ||

| 3. Steel backing 0.4~ 2.2mm | ||

| 4. Tin-plating 0.005mm or copper plating 0.008mm | ||

| Technical Data | Limit Value(Oil) | 22N/mm² |

| Friction Coefficient | 0.05~0.25 | |

| Temperature Range | -40°C~+130°C | |

| Resilience | 70N/mm² | |

| Sliding Speed Limit | 2.5m/s | |

The thickness of the copper layer on the surface of the strip steel. The thickness of the one-sided baked layer of porous bronze CuSn10 on the copper surface of strip steel-backed

A sliding surface of polyacetal layer

Metal-Polymer Composite Thrust Washer Material

Steel Back + Porous Bronze Sinter + Pom With Lubrication Indents

Porous Bronze Sinter

Steel Backing

Tin/Copper coating

SF-2 Thrust Washers Suitable for grease or oil lubrication and all kinds of movement, good load capacity, robust and insensible to dirt.

| Sliding surface: | POM |

| Support material: | Tin plated steel |

| Dynamic load: | ≤ 140 N/mm² |

| Static load: | ≤ 250 N/mm² |

| Sliding speed: | ≤ 2,5 m/s |

| Fricition value: | 0,04 - 0,12 µ |

| max. PV-value: | 2,8 N/mm² x m/s |

| Temperature strain: | -40 up to + 130 °C |

| Maintenance: | maintenance-bound |

| Tolerance housing: | H7 |

| Tolerance after mounting: | in series D |

| Shaft tolerance: | h8 |

| Shaft material: | Steel, hardened or untempered, roughness Rz < 4-6 |

SF-2 POM coated self-lubricating thrust washer for grease or oil lubricated applications.

Standard parts contain grease indents in the sliding layer, plain sliding layer available by request.

Optimum performance under relatively high loads and low speeds.

Suitable for linear, oscillating and rotating movements.

Wide range of parts available from stock.

SF-2 POM based thrust washers is widely used in Vehicle chassis, forming machine tools, steel metallurgical machinery, mineral mountain machinery, hydraulic industry and rolling steel industry etc.

| Material | Part Number | Inner Diameter | Outer Diameter | Thickness |

| POM Wrapped Acetal Lined | SF-2 Thrust Washer12 24 015 | 12 | 24 | 1.5 |

| POM Wrapped Acetal Lined | SF-2 Thrust Washer14 26 015 | 14 | 26 | 1.5 |

| POM Wrapped Acetal Lined | SF-2 Thrust Washer16 30 015 | 16 | 30 | 1.5 |

| POM Wrapped Acetal Lined | SF-2 Thrust Washer18 32 015 | 18 | 32 | 1.5 |

| POM Wrapped Acetal Lined | SF-2 Thrust Washer20 36 015 | 20 | 36 | 1.5 |

| POM Wrapped Acetal Lined | SF-2 Thrust Washer22 38 015 | 22 | 38 | 1.5 |

| POM Wrapped Acetal Lined | SF-2 Thrust Washer24 42 015 | 24 | 42 | 1.5 |

| POM Wrapped Acetal Lined | SF-2 Thrust Washer26 44 015 | 26 | 44 | 1.5 |

| POM Wrapped Acetal Lined | SF-2 Thrust Washer28 48 015 | 28 | 48 | 1.5 |

| POM Wrapped Acetal Lined | SF-2 Thrust Washer32 54 015 | 32 | 54 | 1.5 |

| POM Wrapped Acetal Lined | SF-2 Thrust Washer38 62 015 | 38 | 62 | 1.5 |

| POM Wrapped Acetal Lined | SF-2 Thrust Washer42 66 015 | 42 | 66 | 1.5 |

| POM Wrapped Acetal Lined | SF-2 Thrust Washer48 74 02 | 48 | 74 | 2.5 |

| POM Wrapped Acetal Lined | SF-2 Thrust Washer52 78 02 | 52 | 78 | 2.5 |

| POM Wrapped Acetal Lined | SF-2 Thrust Washer62 90 025 | 62 | 90 | 2.5 |

FOLLOW US ON

HTTP://WWW.BRONZEGLEITLAGER.COM