VIIPLUS INTERNATIONAL |

|

Rocker Arm Bushing Bimetal Bearing Bushes are specialized components designed to provide smooth and reliable operation in rocker arm mechanisms. These bushings are constructed from bimetal materials, which consist of two different metals joined tog to create a unique combination of properties.

The bimetal design offers several advantages. The outer layer, often made of a harder metal, provides excellent wear resistance and durability, ensuring a long service life for the bushing. The inner layer, typically made of a softer metal, offers improved lubrication and reduces friction, enhancing the overall performance of the rocker arm mechanism.

Rocker arm bushings play a crucial role in the smooth operation of internal combustion engines and other mechanical systems. They support and guide the rocker arm as it moves, reducing wear on the mating surfaces and minimizing friction losses. This helps maintain efficient power transmission and reduces the risk of mechanical failure.

The precision manufacturing of rocker arm bushings ensures a snug fit within the rocker arm mechanism. This tight fit helps prevent vibrations and misalignment, further enhancing the reliability and performance of the system.

In summary, Rocker Arm Bushing Bimetal Bearing Bushes are high-performance components designed to provide smooth and durable operation in rocker arm mechanisms. Their unique bimetal design offers a combination of wear resistance, lubrication, and precision fit, making them an essential part of any mechanical system that relies on efficient power transmission.

We are the professional Rocker arm bush producers. Our products perform well under high load conditions. Our bushings maintain tight dimensional tolerances, have an excellent surface finish, are machine-friendly, and have a tapered wire at each end for easy installation.

Copper Lead

· High-quality general polish

· Minimal relief between bearing layer and steel backing to facilitate the assessment of the bond integrity.

· Fully developed and polished islands of Lead to ensure consistency of comparative analysis with standards.

| SAE | Chemical Composition |

| 792 | CuPb10Sn10 |

| CuPb17Sn5 | |

| 797 | CuPb24Sn4 |

| 49 | CuPb24Sn |

| 48 | CuPb30 |

· High-quality general polish.

· Minimal relief between bearing layer, intermediate foil, and steel backing in order to facilitate the assessment of

the bond integrity.

· Also to ensure consistent comparative analysis of type, size, and distribution of different

phases present in the range of alloys.

| SAE | Glacier | Daido | Miba | Chemical Composition |

| AlSn6Cu | ||||

| A600/A590 | AlSn6Si4CuMnCr | |||

| A500 | AlSn8Si2.5Pb2CuCr | |||

| SAE770 | AlSn6.5Cu | |||

| SAE783 | AS16 | AlSn20Cu | ||

| AS20 | AlSn6Si2.5CuNiMnV | |||

| SAE788 | A17X | AlSn12Si2.5Pb1.7Cu | ||

| SA260 | AlSn7CuSi2.5CrZr | |||

| AS104 | AlSn10Si4Cu | |||

| A370 | AlSn20CuMn | |||

| AlZn4.5Mg | AlZn4.5Mg |

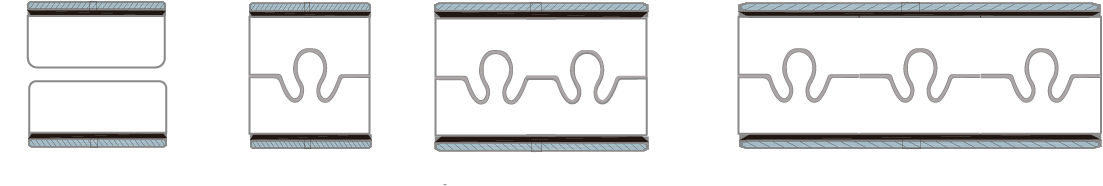

Find here online price details of bimetal bushings which are produced from bimetallic strips with sintered copper-lead-bronze coating and steel as support material.The steel back provides extra strength, while the sintered bronze coating provides a bearing surface which results in reduced friction and wear. Bimetal bushings are widely used for applications with vibrating loads, impacts and friction area.

Sintered Bimetal Bearings SAE799 Layer + Steel Backed Bushings + Copper Plating / Tin-Plating

Bimetal bearing is a steel-backed bushing plate as the matrix, the surface of sintered CuPb24Sn4 alloy material products. The bimetal bushings have good anti-fatigue strength and bearing capacity. Suitable for medium speed medium load. There are occasions for oil sliding. When the surface is plated with soft alloy, it can be used as bearing and connecting rod bushing for the high-speed internal combustion engines to achieve good wear resistance and fatigue resistance.

| Maximum dynamic load | 120P N/mm² | MAX Temperature°C | Grease lubrication | 150°C | |

| Maximum linear velocity | Grease lubrication | 2.5Vm/s | Fluid lubrication | 250°C | |

| MAX PV | 2.8N/mm². m/s | Match the diameter of axle | HRC | ≥ 48 | |

| μ | 0.05~0.15 | Ra | 0.16~0.63 | ||

| Maximum linear velocity | Fluid lubrication | 10 | Alloy layer hardness | 45~70 | |

| MAX PV | 10 | Coefficient of thermal conductivity | 60W/mk | ||

| μ | 0.04~0.12 | Linear expansion coefficient (axial) | 19×10-6/K | ||

Thickness tolerance between inner hole machining and non-machining for bimetal bearings

Nominal Thickness | Tolerances of Series B (non-machinable) | Tolerances of Series C (non-machinable) |

| 1.0 | -0.025 | +0.25 +0.15 |

| 2.0 | -0.030 | +0.25 +0.15 |

| 2.5 | -0.035 | +0.25 +0.15 |

| 3.0 | -0.040 | +0.30 +0.15 |

| 3.5 | -0.045 | +0.30 +0.15 |

| 3.5 | -0.050 | +0.30 +0.15 |

Manufacturer of Self Lubricating Bushing - Self Lubricating Graphite Bush, Self Lubricating Bimetal Bushings

We take quality as the core value of the enterprise.

Bimetal composite bearings with high-quality low carbon steel as substrate, the surface of the sinter with low friction properties of copper alloy CuPb24Sn4 as wear-resisting layer of bearing.

We can design bimetal bearings according to the operating conditions of copper alloy surface processing of various types of oil tank, oil hole, hole, etc., in order to suit cannot continue to go hard or go occasion. Good bonding strength and optimum bearing capacity can be obtained by secondary sintering and secondary extrusion.

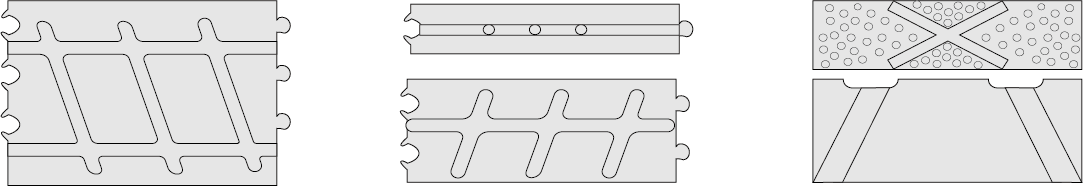

Oil Holes Form

Diamond Form

Smooth (No Oil Pocket)

Bimetal Bearings Bushings Buckle Form

For every industry in the world

High quality self - lubricating products are available at the same time

Professional solutions Bimetal Bearing constantly improve the

quality of

products and services, to meet the challenges of The Times!

Bimetal Bearings Design

Manufacture based on clients’ drawings

Integrated production

International service experience

Viiplus product advantages

High quality products Size detection Design reference standard Global reach On time delivery Multiple packaging

The mode of transportation