VIIPLUS INTERNATIONAL |

|

The CuSn8 Wrapped Bronze Bushing is a type of bronze bushing that is constructed using CuSn8, a specific alloy of copper and tin. This alloy, known for its exceptional wear resistance, corrosion resistance, and good strength, is ideal for applications requiring durable and reliable bushings.

The "wrapped" design of the bushing refers to the fact that the CuSn8 bronze material is wrapped or formed around a central core or mandrel. This construction technique allows for precise shaping and sizing of the bushing, ensuring a tight and secure fit within the application.

CuSn8 Wrapped Bronze Bushings are commonly used in a variety of industrial applications, including pumps, motors, compressors, and other rotating machinery. Their durability and reliability make them a trusted choice for maintaining smooth and efficient operation in demanding environments.

The CuSn8 alloy provides superior wear resistance, ensuring that the bushing can withstand repeated friction and abrasion without excessive wear or damage. Additionally, the corrosion resistance of the alloy helps protect the bushing from rust and corrosion, extending its service life.

Overall, the CuSn8 Wrapped Bronze Bushing is a high-performance bushing solution that offers excellent wear resistance, corrosion resistance, and precise fit, making it suitable for a wide range of industrial applications.

China cusn8 wrapped bronze bushing factories, China lagerbuchse on bronzegleitlager.com. lagerbuchse factories in China, wrapped bronze bushing on bronzegleitlager.com. Fast Shipping. Quality Manufacturers. Factory Price. China Suppleirs.

These bronze bearings have been developed to for slow speed, high load applications, especially suited for oscillating motion and are

perfect for the construction, mining/quarrying, agriculture and

automotive industries.

Our Viiplus range of plain bearings are avialble with lubrication

pockets, thru-holes and grooves. This range is available in metric sizes only.

Our in-house machining service is able to produce non-standard

sizes to suit specific customer requirements.

Wrapped bronze bushing is made of tin-bronze CuSn8P with its surface punched with diamond oil sockets which are preserved for oil saving. It has good anti-fatigue, anti-erosion anti-abrasion and load capacity.

lagerbuchse are made entirely from phosphor bronze CuSn8. CuSn8 is characterized by the purity of the alloy with only a very low level of impurities. Wrapped bronze bearings are produced from strips that are subsequently wrapped and calibrated.

Wrapped bronze bearings must be lubricated with grease or oil on installation. A good quality lubricant is essential as it will reduce friction and wear by forming a film between the plain bearing and the shaft. For heavily contaminated applications, we recommend sealing off the bearing. This will protect both the bearing and the lubricant.

1. Easy for fitting and lubricating

2. High load capacity

3. Inner Diameter machineable parts are available against order

4. High level thermal conductivity

5. Minimum overall dimensions

6. Chemical resistance.

Initial pre-lubrication at assembly required... Chemical

Compositions lagerbuchse are wrapped from a cold formed homogenous bronze (CuSn8) with

exceptional material properties. The standard sizes are fitted with

diamond shaped lubrication indents in the bearing surface. These

indents serve as lubricant reservoirs to rapidly build up a

lubrication film at the start of movement and thereafter reduce the

running friction. The material is suitable for construction and

agricultural machinery applications.

Viiplus lagerbuchse are available in metric sizes as straight or

flanged bushings. They are wrapped from strips and calibrated.

These bushings are an excellent solution for dirty environments

where high levels of contamination make relubrication necessary.

They are resistant to shock loads and vibrations at slow speeds.

The diamond-shaped lubrication pockets in the sliding surface need

to be filled initially with grease. A good quality lubricant

reduces friction and wear by separating a bronze bushing from its

shaft. To protect the bushing and lubricant in highly contaminated

environments, viiplus recommends using seals.

Wrapped bronze bearings are especially suited to severe operating conditions where frequent maintenance is not possible. Common applications are:

– High load capacity

– Works well in dirty environments

– Wide temperature range

– Easy to assemble

– Grease pockets as lubrication reservoirs

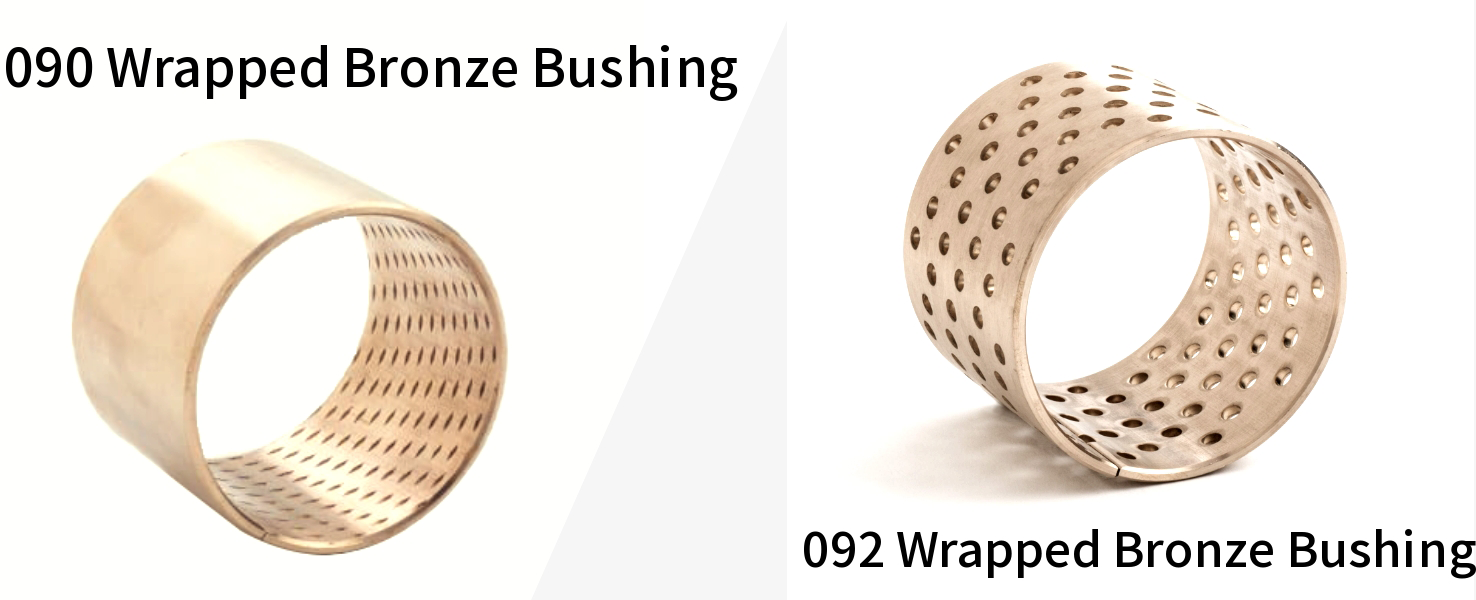

| Properties | 090 | 092 |

| Max. load (Dyn/stat), N/mm2 | 40 / 120 | 40 / 120 |

| Max. sliding speed m/s | 2.0 | 2.5 |

| Max. PV value N/mm2 x m/s | 2.8 | 2.8 |

| Temperature range, oC | -100 / +200 | -100 / +200 |

| Shaft tolerance | e7 - f8 - h6 | e7 - f8 - h6 |

| Housing tolerance | H7 | H7 |

| Shaft roughness | Ra ≤ 0.8 | Ra ≤ 0.8 |

| Shaft hardness | > 200 HB | > 200 HB |

| TECHNICAL DATA | |

|---|---|

| Material: | Cu – 91.3% Sn – 8.5% P – 0.2% |

| Standard: | Cu Sn8. DIN 17662. CW453K |

| Sliding layer (thickness): | Homogeneous |

| Tensile strength Rm: | 450N/mm² |

| Yield strength Rp 0.2: | 250N/mm² |

| Elongation in % A10: | 0.4 |

| Hardness: | 90-120 HB |

| Friction coeff: | 0.08-0.25µ |

| Thermal conductivity: | 60W/m·K |

| Temperature range: | -100°C/200°C |

| Max. load static: | 120 N/mm² |

| Max. load, dynamic: | 40 N/mm² |

| Max. sliding speed (w.lubr.): | 2.5 m/s |

| Pv-value, Mpa x m/s, kont / int: | 2.8 |

| Counter material | |

| Recommended shaft hardness: | >210HB |

| Rec. shaft surface roughness (Ra) | 1.6 |

| Recommended tolerance: | e7-f7 |

| House: | H7 |

1).PV Value

PV value is an effective criterion to calculate the service life of

TCB900/TCB902. If there is need to prolong the service Life, PV value must be

reduced.

2).Environment Temperature

Service life of the TCB900/TCB902 will shorten in higer ambient

temperature .

3).Roughness

Service life of TCB900/TCB902 can be greatly improved if its mating

axis is made of chrome-plated stainless steel with hardness more

than 50HRC and surface roughness among 0.4~0.63.