VIIPLUS INTERNATIONAL |

|

The DP4 flange bushing, equipped with red PTFE (Polytetrafluoroethylene) coated collar bushes, is a high-performance component designed for applications requiring superior wear resistance and low friction. The combination of the DP4 flange bushing and red PTFE coated collar bushes offers numerous benefits in various industrial and mechanical systems.

The DP4 flange bushing itself is a precision-engineered part that ensures accurate alignment and smooth rotation. It is typically made from high-strength materials such as steel or cast iron, which provide durability and long-lasting performance.

The red PTFE coating on the collar bushes is a significant feature of this system. PTFE is a synthetic fluoropolymer known for its excellent lubricity, chemical resistance, and temperature tolerance. The red coating not only enhances the visual identification of the bushes but also serves as an additional protective layer, further improving wear resistance and reducing friction.

The combination of the DP4 flange bushing and red PTFE coated collar bushes is particularly suitable for applications where high loads, high speeds, or harsh environments are present. The low friction properties of the PTFE coating help reduce energy loss and improve efficiency, while the wear resistance ensures long-term performance and reduced maintenance requirements.

Overall, the DP4 flange bushing with red PTFE coated collar bushes is a reliable and efficient solution for various industrial and mechanical applications. It offers superior wear resistance, low friction, and accurate alignment, ensuring smooth and reliable operation of the system.

Metal-Polymer Anti-Friction Bearings

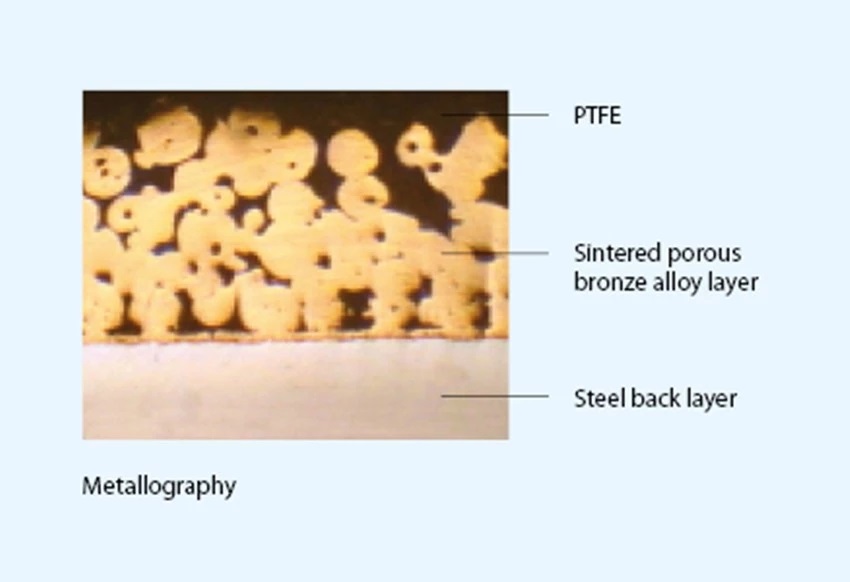

Type (PTFE coated sliding bushing) Steel + porous bronze sinter + PTFE

Lead-free flange bushings have PTFE sliding surfaces and tin-plated steel bodies, making them an effective substitute for places that cannot or must not be lubricated. Select this type for low speed, high load applications, or low speed and high load applications. This sleeve is suitable for applications where friction and heat should be avoided. The sleeve can also be used, for example, in oil or water, and has good corrosion resistance. In addition, the model can withstand very high and very low temperatures and has a low coefficient of friction. For example, in fitness equipment.

Size | Customized |

Material | Bronze + Bronze powder + PTFE |

Color | Natural |

Certification | ISO9001, TS16949 |

Max load capacity P | Static Load 250N/mm², Dynamic Load 140N/mm², Oscoillation Load

60N/mm² |

Max line speed V | Dry Lubrication 2.5m/s,Oil Lubrication >5m/s |

PV value limit | Dry Lubrication 1.8N/mm²· m/s,Oil Lubrication 3.6N/mm²· m/s |

Friction coef u | Dry Lubrication 0.08~0.20, Oil Lubrication 0.02~0.12 |

Max Working temperature | -200~280℃ |

Mating Axis | Hardness >220 HB, Roughness Ra=0.4~1.25 |

Thermal conductivity | 60W/(m·k) |

Coefficient of linear expansion | 18×10-6/K |

Application | metallurgical industry, continuous casting and rolling mill,

concrete machinery and spiral conveyers |

PTFE CDIN 1494 Flange sleeve bushing, Flange Size Bushing, ROHS

Approved

Sliding surface made of PTFE in tinned steel frame

Especially suitable for places where lubrication is not possible or

desirable.

DP4 flanged bearing Suitable for dry running with a low coefficient of friction, low wear rate, good sliding characteristics, the transfer film created will protect the mating metal surface. Suitable for rotary and oscillating movement, high chemical resistance, lower absorption of water and reduced swelling. Also performs well with lubrication.

| PTFE / Fibre + Bronze + Steel + Copper plating / tin-plating |

| Physical and Mechanical Properties | Usage | ||

| Maximum Operating Temperature Tmax | 280°C | dry | good |

| Minimum Operating Temperature Tmin | -200°C | oil lubricated | very good |

| Maximum Static Load Psta,max | 250N/mm² | grease lubricated | good |

| Maximum Dynamic Load Pdyn,max | 140N/mm² | water lubricated | fair |

| Maximum Sliding Speed V-dry | 2.5m/s | process fluid lubricated | good |

| Maximum Sliding Speed V-oil lubricated | 5m/s | ||

| Maximum PV Factor-dry | 1N/mm²·m/s | ||

| Maximum PV Factor-oil lubricated | 10N/mm²·m/s | ||

| Coefficient of friction f-dry | 0.04-0.25 | ||

| Coefficient of friction f-oil lubricated | 0.02-0.08 | ||

| This material meets the demanding criteria for long life and trouble-free performance with or without lubrication. |

| Automotive: tractors, combines, crop sprayers, earthmovers, graders and other construction, auto machines, specific uses in power steering cylinders, steering gear thrust washers, disc brakes, calipers and pistons, shock absorbers, governor linkage, windshield wiper motor, tilt gear assemblies... |

| Business machines: photocopy machines, typewriters, mail sorters, postage meter systems, computer terminal printers and peripheral equipment, automatic printing devices, mail processing machinery... |

| Hydraulics and valves: pumps including gear, rotary, water, axial piston, and other types, ball, butterfly, poppet steam, and other valves and valve trunnions... |

| Home appliances: tape recorders, refrigerators, air conditioners, cleaners, polishers, sewing machines, ovens, dishwashers, clothes washing machines...And materials handling, marine engine, packaging, textile equipment, tools...etc. |

1. PTFE/Fibre mixture thickness 0.01~0.03mm, provides an excellent initial

transfer film, which effectively coats the mating surfaces of the

bearing assembly, forming an oxide type solid lubricant film.

2. Sintered bronze powder thickness 0.20-0.35mm, provides Max.

thermal conductivity away from the bearing surface, also serves as

a reservoir for the PTFE-Fibre mixture.

3. Low-carbon steel, gives exceptionally high load carrying capacity,

excellent heat dissipation.

4. Copper/Tin plating thickness 0.002mm, provides good corrosion resistance.

GENERAL |

| Unit | Value |

Maximum load, p | Static Dynamic | N/mm2 N/mm2 | 250 140 |

Operating temperature | Min Max | °C °C | - 200 280 |

Coefficient of linear thermal expansion | Parallel to the surface | 10-6/K | 11 |

Normal to the surface | 10-6/K | 30 |

| Maximum sliding speed, U | m/s | 2.5 | |

| Maximum pU factor | N/mm2 x m/s | 1.0 | |

| Coefficient of friction | 0.04 - 0.25 * |

| |||

| Maximum sliding speed, U | m/s | 5.0 | |

| Maximum pU factor | N/mm2 x m/s | 10.0 | |

| Coefficient of friction | 0.02 - 0.08 |

| |||

| Shaft surface roughness, Ra | Dry Lubricated | µm µm | 0.3 - 0.5 ≤ 0.05 - 0.4 * |

| Shaft surface hardness | Unhardened acceptable, improved bearing life > 200HB | ||

| Dry | Good |

| Oil-lubricated | Very Good |

| Grease lubricated | Good |

| Water lubricated | Fair |

| Process fluid lubricated | Good |