VIIPLUS INTERNATIONAL |

|

The Low Maintenance Standard Solution P20 Composite Bearing is a highly reliable and cost-effective solution for various industrial applications. This composite bearing is designed to provide superior performance while requiring minimal maintenance, making it an ideal choice for demanding environments where downtime is critical.

The P20 Composite Bearing features a unique combination of materials that offer exceptional wear resistance, strength, and durability. The composite material is engineered to resist corrosion, chemical attack, and thermal degradation, ensuring a long service life.

The low maintenance design of the P20 Composite Bearing significantly reduces the need for routine inspections and replacements. This not only saves on maintenance costs but also minimizes production downtime, improving overall efficiency.

In addition to its durability and low maintenance requirements, the P20 Composite Bearing also offers excellent load-bearing capacity and smooth operation. It is suitable for use in a wide range of applications, including machinery, equipment, and vehicles that require precision and reliability.

Overall, the Low Maintenance Standard Solution P20 Composite Bearing is a top-quality product that provides exceptional performance and value for money. Its durability, low maintenance requirements, and smooth operation make it a dependable choice for any industrial application.

The P20 bearings will be distributed by the orifice according to process characteristics according to ISO 3547 with a sliding wall in advance on the surface in contact with the parts. This design is well suited for ground maintenance of grease or liquid lubrication applications.

1. Low adhesion with parts during movement

Low friction and high wear resistance

3. The material has certain clearance and deformation, which can absorb the impurities produced by the movement and thus improve the life.

4 Corrosion resistance can be based on the actual use of galvanized and other solutions.

The stainless steel matrix has good chemical resistance

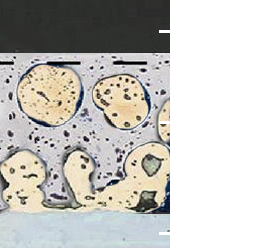

1. Running-in layer

| PTFE matrix with bulking agent | |

| Layer thickness [mm]: | max. 0.03 |

2. Sliding layer

| Tin-lead-bronze | |

| Layer thickness [mm]: | 0.20–0.35 |

| Pore volume [%]: | approx. 30 |

3. Bearing back

| Steel | |

| Steel thickness [mm]: | Variable |

| Steel hardness [HB]: | 100–180 |

Base material: POM+ bronze powder + steel back + electroplating (copper/tin)

Ultimate dynamic load: 140N/mm

Maximum PV value: grease lubrication: 2.8n /mm. M /s

Friction coefficient: 0.05~0.25

Maximum load P: static: 250N/mm dynamic: 150N/mm

Maximum operating temperature: 130℃

Maximum sliding speed: grease lubrication :2.5m/s

Thermal conductivity: < 42W/m.k

Processing: standard | to figure processing

Available form: bushing sliding block sliding plate bearing bush

| shaft | housing | ID | OD | Wall thickness | Oil hole | L 0 -0.40 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| h8 | H7 | d | D | T | h- | 10 | 12 | 15 | 20 | 25 | 30 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 0 -0.022 | 12 | +0.018 0 | 10 | 12 | 0.980 0.955 | 4 | 1010 | 1012 | 1015 | 1020 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 0 -0.027 | 14 | " | 12 | 14 | " | " | 1210 | 1212 | 1215 | 1220 | 1225 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14 | " | 16 | " | 14 | 16 | " | " | 1415 | 1420 | 1425 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | " | 17 | " | 15 | 17 | " | " | 1510 | 1512 | 1515 | 1525 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | " | 18 | " | 16 | 18 | " | " | 1615 | 1620 | 1625 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 | " | 20 | +0.021 0 | 18 | 20 | " | " | 1815 | 1820 | 1825 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 0 -0.033 | 23 | " | 20 | 23 | 1.475 1.445 | " | 2015 | 2020 | 2025 | 2030 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 22 | " | 25 | " | 22 | 25 | " | 6 | 2215 | 2220 | 2225 | 2230 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 | " | 27 | " | 24 | 27 | " | " | 2415 | 2420 | 2425 | 2430 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | " | 28 | " | 25 | 28 | " | " | 2515 | 2520 | 2525 | 2530 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 28 | " | 32 | +0.025 0 | 28 | 32 | 1.970 1.935 | " | 2820 | 2825 | 2830 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | " | 34 | " | 30 | 34 | " | 3020 | 3030 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32 | 0 -0.039 | 36 | " | 32 | 36 | " | " | 3220 | 3230 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | " | 39 | " | 35 | 39 | " | " | 3520 | 3530 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36 | " | 40 | " | 36 | 40 | " | " | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 37 | " | 41 | " | 37 | 41 | " | " | 3720 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | " | 44 | " | 40 | 44 | " | 8 | 4020 | 4030 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45 | " | 50 | " | 45 | 50 | 2.460 2.415 | " | 4520 | 4530 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | " | 55 | +0.030 0 | 50 | 55 | " | " | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 55 | 0 -0.046 | 60 | " | 55 | 60 | " | " | 5520 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | " | 65 | " | 60 | 65 | " | " | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1, with high mechanical strength and rigidity;

2. The Maximum fatigue strength;

3. Good environmental resistance and organic solvent resistance;

Strong resistance to sustained impact;

5. Widely used temperature ranges from -40℃ to 120℃.

6. Good electrical properties.

7. Good recovery.8, with their own lubrication, good wear to

hold;9. Excellent dime

Melting point of 175 ° C

Density 1.42 g/mL at 25 °C

Flash point 158 °F storage condition 2-8°C

| Performance indicators | Date | |

| Maximum load P | Static load | 250N/mm² |

| Dynamic load | 150N/mm² | |

| highest line speed V | Grease lubrication | 2.5m/s |

| High PV value | Grease lubrication | 3.6N/mm²・m/s |

| Coefficient of friction | Grease lubrication | 0.05~0.25 |

| The use of temperature | -40℃~+130℃ | |

| Coefficient of thermal conductivity | 4W/m・K | |

| Coefficient of thermal expansion | 12×10-6/K | |

Click here for PDF for more product information