VIIPLUS INTERNATIONAL |

|

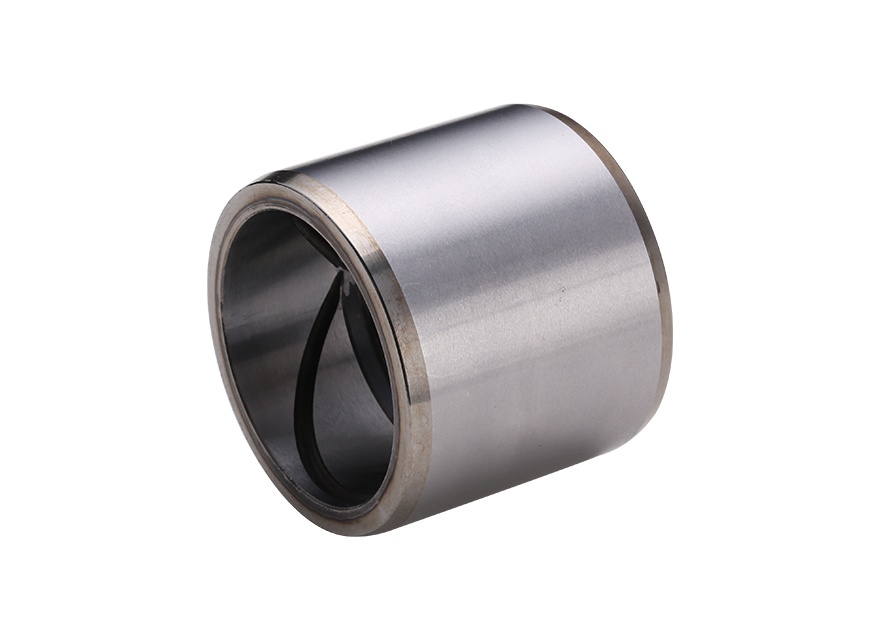

Specialized in the production of GCR15 bearing steel sleeve special hard wear-resistant steel sleeve wear - resistant self - lubricating steel sleeve

GCR15 bearing steel sleeve extra hard steel sleeve self - lubricating wear-resistant steel sleeve.

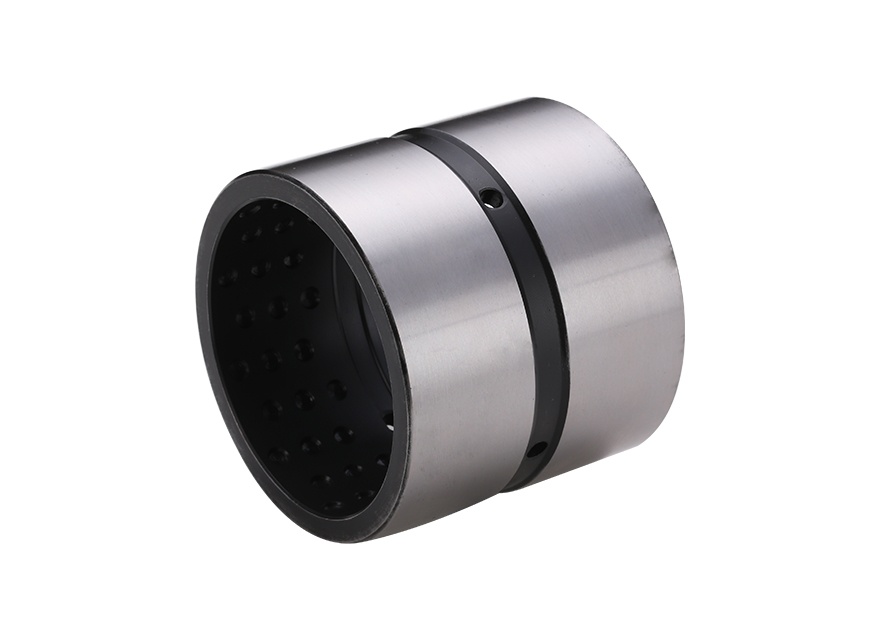

In a variety of grades of steel as base material, according to a certain proportion according to the operating conditions in the working face processing out of the cavity and fill in the solid lubricant, steel alloy provides high bearing capacity and solid lubricant is lower friction pair can be formed, under the condition of high load low speed showed its excellent lubricating is solid inlaid reinforced products, has a very high compression performance. When the embedded graphite is working, the lubrication particles are discharged, so that a layer of diaphragm is produced between the shaft and the sleeve, which has the advantages of anti-bite than the monomer oil lubrication.

It is especially suitable for supporting parts of lifting machinery, such as mold guide post, mold frame of injection molding machine, soil rolling machine, crane support, etc.

Specific size can refer to JDB-650 standard, can also be matched with steel shaft production.

Solid bushing for industrial applications. Your global partner for sliding bearing technology. Order Bushings Online. Range Of Products. View www.viiplus.com; Plain Bearing types available in standard dimensions: Cylindrical bushes, Flanged bushes, Thrust washers, Flanged washers, Sliding plates.

Product Type: | Solid bushing |

Application : | Excavators,Cranes,Construction Machine复制 |

Material: | GCr15, 40Cr, C45 |

Hardness : | 52~60HRC |

Max Dynamic Load: | 250N/mm² |

Max Linear Velocity: | 0.1m/s |

Max PV Value | 1.5 N/mm².m/s |

Working Temperature Limit | -100~+350℃ |

Linear Expansion Coefficient | 1.1×10-5/℃ |

In addition to the standard product catalog is displayed, we

provide non-standard product or to order according to customer

requirements. | |

GCR15 Hardened Steel Sleeve Bearing Groove Bushing Size

d | D | IDF7 | ODm6 | L-0.10 -0.30 | |||||||||||||||

8 | 10 | 12 | 15 | 16 | 20 | 25 | 30 | 35 | 40 | 50 | 60 | 70 | 80 | ||||||

8 | 12 | 8 | +0.028 +0.013 | 12 | +0.018 +0.007 | 081208 | 081210 | 081212 | 081215 | ||||||||||

10 | 14 | 10 | 14 | 101408 | 101410 | 101412 | 101415 | 101420 | |||||||||||

12 | 18 | 12 | +0.034 +0.016 | 18 | 121810 | 121812 | 121815 | 121816 | 121820 | 121825 | 121830 | ||||||||

13 | 19 | 13 | 19 | +0.021 +0.008 | 131910 | 131915 | 131916 | ||||||||||||

14 | 20 | 14 | 20 | 142010 | 142012 | 142015 | 142020 | 142025 | 142030 | ||||||||||

15 | 21 | 15 | 21 | 152110 | 152112 | 152115 | 152116 | 152120 | 152125 | 152130 | |||||||||

16 | 22 | 16 | 22 | 162210 | 162212 | 162215 | 162216 | 162220 | 162225 | 162230 | 162235 | 162240 | |||||||

18 | 24 | 18 | 24 | 182412 | 182415 | 182416 | 182420 | 182425 | 182430 | 182435 | 182440 | ||||||||

20 | 28 | 20 | +0.041 +0.020 | 28 | 202810 | 202812 | 202815 | 202816 | 202820 | 202825 | 202830 | 202835 | 202840 | 202850 | |||||

22 | 32 | 22 | 32 | +0.025 +0.009 | 223212 | 223215 | 223220 | 223225 | |||||||||||

25 | 33 | 25 | 33 | 253312 | 253315 | 253316 | 253320 | 253325 | 253330 | 253335 | 253340 | 253350 | 253360 | ||||||

30 | 38 | 30 | 38 | 303812 | 303815 | 303820 | 303825 | 303830 | 303835 | 303840 | 303850 | 303860 | |||||||

35 | 45 | 35 | +0.050 +0.025 | 45 | 354520 | 354525 | 354530 | 354535 | 354540 | 354550 | 354560 | ||||||||

40 | 50 | 40 | 50 | 405020 | 405025 | 405030 | 405035 | 405040 | 405050 | 405060 | 405070 | 405080 | |||||||

45 | 55 | 45 | 55 | +0.030 +0.011 | 455530 | 455535 | 455540 | 455550 | 455560 | ||||||||||

50 | 60 | 50 | 60 | 506030 | 506035 | 506040 | 506050 | 506060 | 506070 | 506080 | |||||||||

The process of quenching quality of GCr15 steel bearing rings I. The process of expanding the common defects of bearing rings during quenching and cooling

Oil is widely used as quenching medium for bearing parts. The main

reason for GCr15 steel sleeve is that the cooling rate of oil is

very slow in the third stage (convection period) of cooling

process. In the previous production of No. 10, No. 20 machine oil

in 650~500℃ between 20~50℃/s. The convection stage starts from

about 300℃ and continues to room temperature, which is just in line

with the cooling rate that the martensite temperature of bearing

steel requires less, so that the deformation and cracking tendency

of bearing parts are greatly reduced in the quenching process.

However, the operation mode is to use manual hoist to hoist the

ring into the oil, and the frequency and amplitude of the ring

moving up and down in the oil are controlled by the operator

manually, which is difficult to meet the process requirements, that

is, the time of the ring moving through the oil is not less than 3S

/mm. Therefore, in the cooling process, the ring often appears the

following quality problems: 1) poor hardness uniformity: the same

batch of ring hardness divergence HRC > 2, the same ring

hardness uniformity HRC > 1 or 2. 2) Regional or local soft

spots appear on the surface of the ring. 3) For the ring with an

effective wall thickness of BBB 0 7mm, reticular trositic sites

appeared in the microstructure of the 45 steel sleeve.

According to the quality analysis of heat treatment in 1998, the

number of furnaces that need to be repaired due to poor cooling is

51.5% of the repair rate of quenched bronze bushing fire. The

defects of the rings in the cooling process lead to the decrease of

bearing hardness and strength, wear resistance and fatigue

resistance.

Process of quenching quality of GCr15 steel bearing ring

The following measures have been taken for the problems of the ring

during cooling:

1. Without changing the cooling method, increase the quenching

heating temperature of the ring (select the upper limit

temperature) to increase the stability of supercooled austenite in

the steel, thus reducing the critical cooling rate of GCr15 steel.

However, with the increase of heating temperature, the secondary

carbides dissolve too much in the steel, leading to the larger

austenite grains, and the effect of hindering the growth of

martensite is weakened. The hardness difference of the same ring is

larger, and the maximum difference is HRC2. There are still a few

small massive taustenite in the quenched and tempered structure

from time to time. At the same time, fine acicular martensite also

began to appear. Under 500 x metallographic microscope, acicular

martensite (superheated tissue) could be seen clearly. The

quenching deformation increases sharply, and the over-error rate of

diameter variation increases from less than 10% to more than 20% on

average, and the mechanical properties of the parts deteriorate

relatively.

2. Use a fast quenching oil with a faster cooling rate. Due to the

limitation of objective conditions, in the production, a small

amount of water is inevitably entered into the oil tank, which will

gradually emulsify the oil in the use process, change the

performance, lose the good cooling effect, and make the quenching

quality can not reach the ideal effect.

Process of quenching quality of GCr15 steel bearing ring

Research and application of new heat treatment technology for

bearing rings

The cooling and hardening capacity of quenching medium is an

important factor affecting the heat treatment quality of bearing

rings. Obviously, this is related to the metallurgical factors of

the workpiece, the shape of the C curve and the cooling conditions.

And the quenching medium with strong cooling capacity can make the

hardness of the workpiece after quenching higher or the hardening

layer deeper. In practice, the key to ensuring hardening is a

sufficiently large cooling rate at the nose tip of the C curve, but

a relatively small cooling rate is required during martensite

transformation. The application of the new technology is adapted to

this characteristic. By changing the relative speed of the

workpiece and the quenching oil, and changing the cooling and

hardening ability of the quenching medium, the ideal quenching

quality can be obtained to meet the requirements of different

cooling rates for the structure formation of the workpiece at

different temperatures.

1. Cooling strength test analysis

Through many tests and analyses, it is shown that the cooling

strength of the oil can be improved by changing the cooling method

with the new technology, so as to improve the quality of heat

treatment. The cooling strength H is a parameter reflecting the

cooling capacity of the medium, H=αλ/2 (α is the interfacial heat

transfer coefficient; λ is the thermal conductivity of steel). The

H value for still water is 0.1. The greater the value of H, the

stronger the cooling capacity of the medium. In the test, according

to the quenching medium under different agitating conditions, the

change of cooling strength is shown in Table 1. When the quenching

is carried out by strongly agitating the oil, the H value can reach

0.7. In general, the H value of oil quenching is 0.3.

2. Microstructure and hardness test analysis

Ring in the process of testing the product model at 314/01,

quenching temperature is 840.40 ℃, machine oil, coolant for 10

rings in static quenching and cooling conditions, through many

experiments, it is concluded that ring troostite level changes in

the microstructure, ring in static and dynamic cooling conditions,

organization closely size differ about 5 ~ 10 times, Under the

channeling cooling condition, the hardness difference of the same

ring is reduced to 0.5.

3. Application of new process and equipment improvement

The new process is to change the production facilities, change the

quenching oil and water jacket cooling into circulating cooling,

use a large flow oil pump to inject the cooled oil from the bottom

of the quenching tank, first form a circulation under the funnel,

rise evenly, and then through two layers of orifice plate to form a

uniform dark gushing oil column upward injection, the oil surface

in the oil tank is boiling. And can change the output flow of the

oil pump, change the relative movement speed of the ring and oil,

to meet the requirements of different cooling rates in the process

of the formation of the workpiece, and at the same time, the upper

hot oil is pumped out in time so that the oil temperature of the

upper and lower layers in the oil groove is basically balanced. The

oil cooling filtration system not only makes the oil can be fully

cooled, but also makes the oil can be very good purification. The

new process not only meets the high cooling rate requirements of

GCr15 steel under high-temperature condition, ensures the quenching

hardness and homogeneity of quenching, but also meets the critical

quenching rate required by the austenite with fine grains and low

carbon and chromium content produced by the austenitizing of the

workpiece at a lower temperature, refining the martensite matrix

structure. Avoid quenching crack, make the bearing ring quenching

hardness stable control in HRC64~65.5, quenching microstructure of

2~3 grade. With 2 levels as most, the outer diameter of ¢100mm or

more after quenching the diameter of the ring change over the error

rate reduced to about 7%, the surface brightness of the workpiece

after quenching increased, all qualified quality, reduce the loss

of waste and repair.

Production facilities improvement is hot quenching tank

upper-middle-class oil overflow to the filtration unit, and then

into a set of overhead of brass tube cooler in (place) in the

cleaning cycle pool, and then after cooling in oil pump oil pump

into the bottom of the quench tank, between two layers of aperture

is ¢5 mm, pitch of 20 mm x 20 mm of porous plate, orifice on the

second floor of a staggered, Ensure the uniform rise of cooling

oil.

VIIPLUS is dedicated to the research and manufacture of all kinds of bushings,spare parts,machinery parts and precision parts. We are approved by the third party concerning the quality certificate. Up to now, we have provied a total of ten categories of products,including composite self-lubricating bushing, boundary lubricating bushing, bimetal bushing, oil sintered bushing,solid lubricating bushing with graphite, steel bushing, casting copper bushing, wrapped bronze bushing,spherical plain bearing and filament wound bearing. The quality and performance have met or exceed international standards.

| Material&Bearing Properties | Unit | Value | Unit | Value | ||

| Max.dynamic load | MPa | 250 | psi | 36,200 | ||

| Operating Temperature | °C | ‘-100 to 350) | °F | -148 to 662 | ||

| Grease Lubrication | ||||||

| Max.sliding speed | m/s | 0.1 | fpm | 19.7 | ||

| Max.PV Value | m/s | 1.5 | psi x fpm | 43,500 | ||

| Min.Hardness | HRC | 55 | HRC | 55 | ||

| Material&Bearing Properties | Unit | Value | Unit | Value | ||

| Max.dynamic load | MPa | 100 | psi | 14,500 | ||

| Operating Temperature | °C | ‘-100 to 250) | °F | -148 to 482 | ||

| Grease Lubrication | ||||||

| Max.sliding speed | m/s | 0.5 | fpm | 100 | ||

| Max.PV Value | m/s | 1.5 | psi x fpm | 43,500 | ||

| Min.Hardness | HV | 600 | HV | 600 | ||

| Material | 1. Stainless Steel: SS303, SS304, SS316, SUS420J2, etc 2. Steel: 12L14, 12L15, C45(AISI1045), etc 3. Carbon Steel: CH1T, ML08AL, 1010, 1035, 1045, etc 4. Alloy Steel: 10B21, 35ACR,40ACR, 40Cr, 35CrMn, etc 5. Aluminum or Aluminum Alloy: Al6061, Al6063, etc 6. Brass: C3604, C38000, etc |

excavators, cranes and some crucial parts of the construction

machine.