VIIPLUS INTERNATIONAL |

|

Our POM bushes are self-lubricating plain bearings that come in a split type design and standard size, making them suitable for a wide range of applications. The POM material used in these bushes offers excellent wear resistance and mechanical properties, ensuring smooth and reliable operation.

The self-lubricating feature of these bearings eliminates the need for regular lubrication, reducing maintenance requirements and operational costs. The split type design allows for easy installation and removal, making maintenance and replacement a breeze.

The standard size of these POM bushes ensures compatibility with a variety of machinery and equipment, making them a versatile and cost-effective solution. Whether you need bearings for industrial machinery, automotive components, or any other application where self-lubricating, split-type plain bearings are required, our POM bushes are an excellent choice.

Contact us today to learn more about our POM bushes and how they can enhance the performance and reliability of your machinery and equipment. We are committed to providing you with the best possible solution for your specific needs.

VIIPLUS bearings utilize special polymer liners for self-lubrication and improved wear properties. Each material has a specific wear rate dependent on the speed, load, temperature, lubrication and hardware of the application. The metal backingsupports liner materials made to withstand high loads, speeds and adverse environments. The advantage of the VIIPLIUS design is that even if wear-thru occurs in the liner,

the supporting interlayer is a self-lubricating material as well.

Sintered porous bronze on metal substrate with POM calendared into the dynamic wear surface.Requires boundary lubrication for optimum performance . High PV rating,Low speeds. Commonly used in mining equipment, rolling mills, skilifts and other applications where bronze bushings are utilized.

International supply of technical industrial goods, in particular wrapped sleeves (self lubricating or for lubrication), personalized POM bushes,

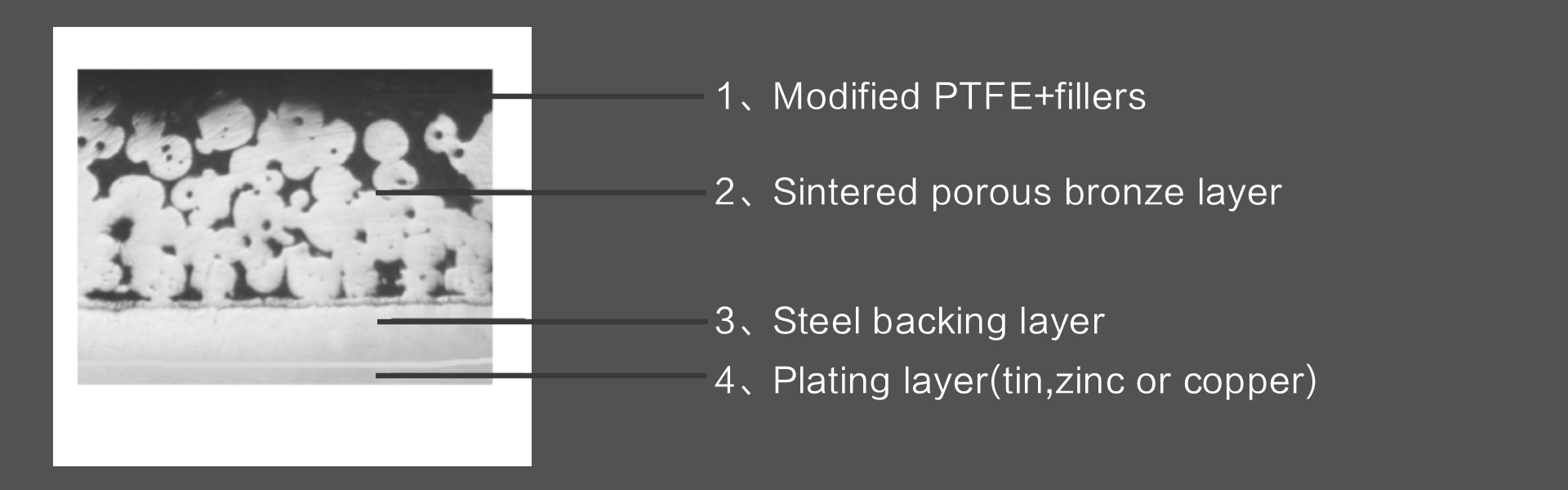

POM composite dry sliding bushings Suitable for rotational and vibrational movements, less maintenance requirements due to longer relubrication intervals, shorter wear,lower susceptibility to edge loading, no absorption of water and therefore no swelling, good damping behaviours, good resistance to shock loads.Pom composite dry sliding bushing, Ring maker, Mfg Bushes, The Pom composite dry sliding bushing is based on a composite material with 3 firmly bonded layers: steel as a base, spherical sintered bronze powder as an intermediate layer and modified POM as a coating layer. It is well suited to low speeds, difficult operating conditions and normal temperatures, it saves costs and extends its service life with the normal replacement of all copper rings.

It is especially suitable for rotating and swaying motion under

heavy load and low speed, as well as opening and closing under

load, which is not easy to form fluid lubrication.Under the

condition of boundary lubrication, it can be used for a long time

without refueling and maintenance.The plastic layer on its surface

can leave a certain amount of margin in the shaft sleeve forming

process, and can be processed by itself after pressing into the

hole, so as to achieve a better assembly size.

At present, it is mainly used in metallurgical machinery, mining

machinery, water conservancy machinery, automobile chassis,

construction machinery, agricultural machinery, steel rolling

machinery and so on.

1. The mixture of modified POM and lead is 0.3-0.5mm, which has high wear resistance and low friction coefficient even in the case of instantaneous oil shortage.Pom composite dry sliding bushing surface is arranged regularly with spiral Angle of oil storage pit, assembly, must be covered with grease.

2. Copper powder layer 0.2mm ~0.3mm, with good bearing capacity and wear resistance, good thermal conductivity can timely transfer the heat generated in the process of bearing operation.The composite material can infiltrate into the gap of the copper powder ball and improve the bonding strength.

3. Low carbon steel 0.4~2.2mm, improve bearing capacity and heat transfer.

4. Copper/tin plating, copper plating 0.008mm, tin plating 0.005mm,so that the bearing has a good corrosion resistance.

The superior performance of smooth polymer metal rings is based on

their unique composite structure:

·Impregnated anti-friction coating enriched with PTFE and fillers

or extruded thermoplastic tape

·Porous sintered bronze spacer for high wear resistance

·Steel or bronze support for high mechanical resistance

The Dry sliding Bushing sleeve can be used in rotating and swinging applications. Lower maintenance requirements thanks to long relubrication intervals. Less wear, less susceptibility to edge loading and no water absorption. THX has good damping qualities and is resistant to shock loads.

·Support material Steel tin-plated

·Intermediate layer Sintered bronze

·Sliding layer Acetal resin / POM

·Improve efficiency with pom composite dry sliding bushing low-friction bearings

·Extended service life

·Zero maintenance

·Compact, lightweight designs

·Reduced noise

·Quick, simple assembly

·Improved operational efficiency

| Max. Load | Static | 250 N/mm2 (36,000 PSI) |

| Very Slow Speeds | 140 N/mm2 (20,000 PSI) | |

| Rotating / Oscillating | 60 N/mm2 (8,600 PSI) | |

| Max. PV | 3.0 N/mm2*m/s (85,000 PSI-FPM) | |

Temperature Range | -40°C to +130°C (-40°F to +260°F) | |

| Max. Speed | Greased | 0.5 m/s (100 FPM) |

| Oiled | 2.5 m/s (500 FPM) | |

| Thermal Conductivity | 4 W(m*K)-1 | |

| Coefficient of Thermal Expansion | 11*10-6*K-1 | |

| Coefficient of Friction | 0.05 - 0.20 | |

Straight bushings

Flange bushings

Thrust washer

strip

Non-standard products are also avalidable

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

·Housing Ø H7

·Bushing inner-Ø after mounting In the range of D

·Shaft tolerance H8

| Dry | Poor |

| Oil lubricated | Good |

| Grease lubricated | Very Good |

| Water lubricated | Poor |

| Process fluid lubricated | Poor |

·Due to their good sliding properties and compact design, these

composite dry sliding bushing are particularly suitable for pom

composite dry sliding bushing arrangements where:

·Maintenance-free operation is a prerequisite

·There is a risk of starvation of the lubricant

·Lubricants may not be used or prohibited.

·Space is limited.

Recommended for applications involving intermittent operation or

boundary lubrication.

Automotive: suspension joints, kingpin assemblies, automobile driving joint

hinges, steering and other linkages, articulation

joints, and rear chassis hinges.

Machine Tools: spindles in drill, grinding, and milling machines,and ram guide plates in multi ram presses.

Agricultural Equipment: gearboxes, clutch assemblies, bale trips and wheel caster swivels for bale accumulators, front axle pivot bearings, steering idler box bearings and kingpin bearings for harvesters...

The pom composite dry sliding bushing is especially well suited for applications where lubricant cannot be supplied continuously or repeatedly.

Standard cylindrical bushings, thrust washers, flanged bushing and strips are available.

Metric bearings and imperial bushings made to order: standard bushing forms in special dimensions, half-bushings, special shapes obtained by stamping, bearings with locating notches, lubricant holes and machined grooves, customized bushing designs