VIIPLUS INTERNATIONAL |

|

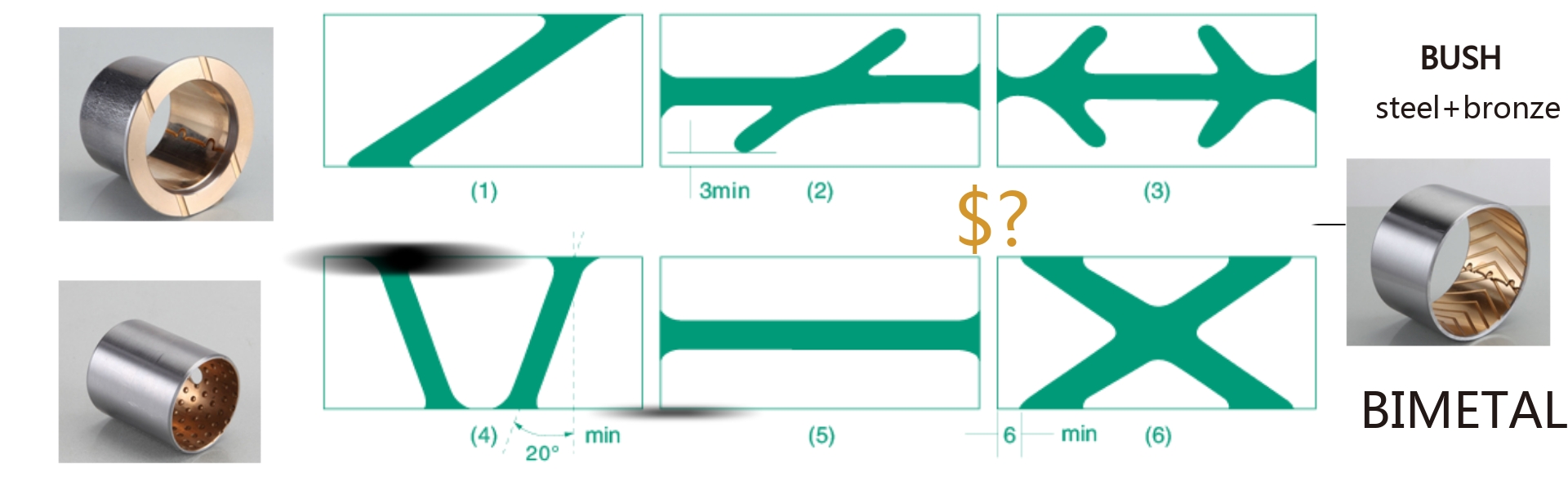

Groove Split Bimetal Wrapped Bearings with Steel Backing and Copper

Plating are a type of bearings that combine the durability of steel

with the wear-resistant properties of copper plating. These

bearings are designed with a split or segmented structure, often

referred to as "groove split," which allows for easier installation

and removal, especially in tight spaces or applications where

traditional bearings may not fit.

The steel backing provides the necessary strength and rigidity to

support the bearing and handle the loads and stresses it

encounters. The copper plating, on the other hand, acts as the wear

surface and is chosen for its excellent wear resistance and ability

to withstand friction and abrasion. The combination of steel and

copper plating results in a bearing that is strong, durable, and

able to handle high loads and harsh operating conditions.

Groove Split Bimetal Wrapped Bearings are commonly used in a wide

range of applications, including machinery, construction equipment,

automotive components, and more. They are particularly suited for

applications where traditional bearings may not be feasible due to

space constraints or installation challenges. The split design

allows for installation without disassembling the entire machine or

component, saving time and effort during installation and

maintenance.

In summary, Groove Split Bimetal Wrapped Bearings with Steel

Backing and Copper Plating offer a durable and wear-resistant

bearing solution for applications requiring strength, reliability,

and ease of installation.

Viiplus Bimetal Bronze Bushing.Sintered Bi-Metal Bushing.BiMetal Bushing Technologies .Bimetal

Bronze Cylindrical Bushings SAE799 797 In Oil & Gas Hydraulics

Industry.We Stock and Manufacture Bimetal Lead-Free Plain Bearings

Solutions

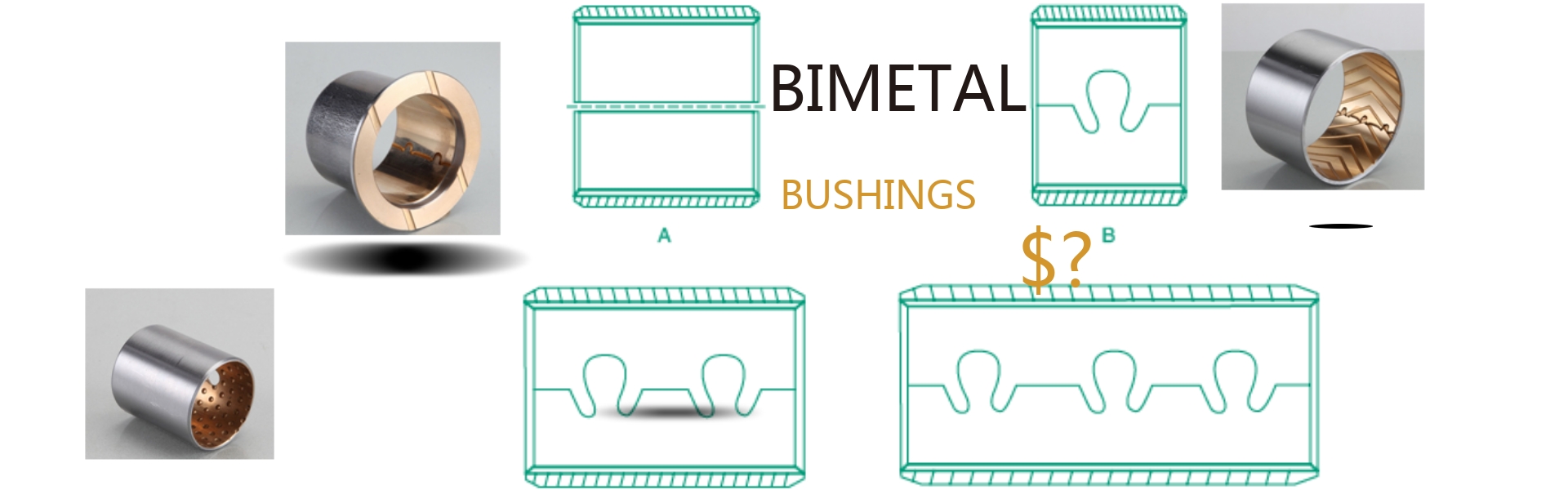

Bimetallic bearing Oil Tank Form Buckle Form

Bimetallic bearings with steel backing are ideal for applications

with high loads & rough operating conditions. Wear resistance.

Consult VIIPLUS CHINA PURCHASEING for a quote.

Bimetal bearing with steel back and sintered CuPb24Sn4 as lining.This type has fairly good performance in anti-fatigue

and heavy load capacity.It is suitable for middle speed and middle

load.When soft alloy is plated on the bushing surface and with oil

lubrication,it can be applied in high-speed internal combustion engine and connect-rod.

Bimetal bearing, is a steel plate as the matrix, the surface

sintered CuPb24Sn4 material products, the product due to high lead content, so it has

a good anti-bite shaft and different physical buried, if the surface of the work of soft alloy material, can be used as

high-speed, low load internal combustion engine spindle bush, connecting rod bushing, rocker arm

bushing;Friction disc on pump side.

bimetal bearing is a kind of bimetal bush. This type

self-lubricating bearing has common structure with other bimetal

bearings.

Low carbon steel + bronze alloy (CuPb24Sn4)

Suitable for middle speed and middle loading, oil lubrication situation

When soft alloy is plated on the bushing surface and with oil

lubrication, PVB033 bimetal bushing can be applied in high speed internal-combustion engine and connect-rod.

(JF-720) Alloy CuPb24Sn4 Chemical Composition ( % )

Cu | Pb | Sn | Zn | P | Fe | Ni | Sb | other |

rest | 21-27 | 3-4.5 | ≤ 0.5 | ≤ 0.1 | ≤ 0.7 | ≤ 0.5 | ≤ 0.2 | ≤ 0.5 |

Load capacity | 38N/mm2 |

Max. Temperature | 170 [ °C ] |

Liner Hardness | HB 45-70 |

Bushing inner-Ø after mountingH9

Shaft tolerancef7 to h8

is a low-maintenance composite sliding bearing, but primary lubrication is necessary. Oil or grease lubrication is possible. Due to solid lubricant storages, lubrication clearances are reduced to a minimum!

Special dimensions are available on request

Send us an online enquiry

You can use our “Enquiry Form” to get in touch with us. One of our

sales team will contact you immediately.

OE code | Customized | Item name | Copper Bush, Bimetal Bush |

Car make | Customized | Unit price | Please contact us |

MOQ Quantity | 500 pieces | Certification | IATF 16949:2016 |

Packing details | Neutral package | Warranty | 1 years |

Payment terms | TT 30% as deposit | Delivery time | According to production |