VIIPLUS INTERNATIONAL |

|

The Garlock POM Bushing, made from Polyoxymethylene (POM) or also known as Acetal, is a high-performance bushing that offers exceptional properties such as wear resistance, rigidity, dimensional stability, and good fatigue strength. POM bushings are commonly used in applications where precision, durability, and low friction are critical.

POM, as a material, has excellent mechanical properties and is resistant to many chemicals, solvents, and fuels. This makes it suitable for use in a wide range of industries, including automotive, machinery, and electronics.

Garlock, as a manufacturer, is renowned for its high-quality products and precision engineering. Garlock POM bushings are precision-manufactured to ensure accurate fits and smooth operation. They are often used in bearings, slides, and other moving parts where low friction and long-lasting performance are essential.

The combination of POM's material properties and Garlock's manufacturing expertise results in a bushing that is reliable, durable, and able to withstand the rigors of demanding applications. Whether it's a high-speed machinery component or a precision-engineered bearing, Garlock POM bushings are a trusted choice for ensuring smooth and efficient operation.

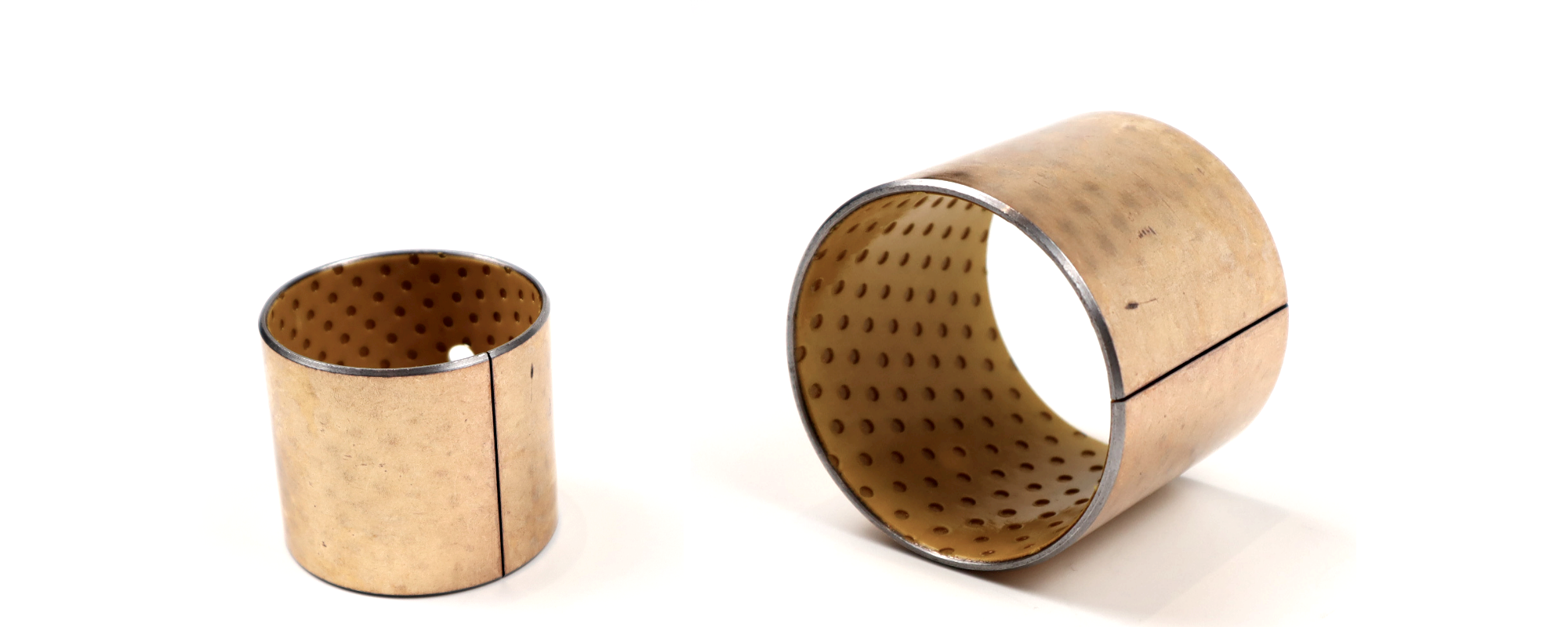

steel backed copper bushing

All the high-quality sleeve bushings products you need are in China. Tell us! We will immediately select the suitable self-lubricating sleeve bushings for you. Contact us today!

| Physical & Mechanical Properties | ||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||

| Usage Range | ||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||

| Possible Application | ||||||||||||||||||||||||||||||

| Automotive: Steering gear, power steering, pedal bushes, seat slides, king-pin bushes, tailgate pivots, brake caliper bushes, etc. Industrial: Mechanical handling and lifting equipment, machine slides, hydraulic cylinders, hydraulic motors, ski-lifts, pneumatic equipment, medical equipment, textile machinery, agricultural equipment, scientific equipment, etc. | ||||||||||||||||||||||||||||||

| Standard Parts Available | ||||||||||||||||||||||||||||||

| Cylindrical Bush | Thrust Washer | Strip / Plate | ||||

| Metric | Inch | Metric | Inch | Metric | Inch | |

VIIPLUS tribology solution is never limited by materials and

shapes. How can you find the most suitable solution in the fastest

way?

Made to order from china http://www.bronzegleitlager.com, quickly find the size parameters and other information needed by

the engineer

1.POM thickness 0.30~0.50 mm, it provides high wear resistance and low friction even with only minute volume of lubricant are supplied, this

bearing surface carries a pattern of circular indents which should

be filled with grease on assembly of the bearing.

2. Sintered bronze powder thickness 0.20-0.35mm, provides max.

thermal conductivity away from the bearing surface, also serves as

a reservoir for the resin mixture.

3. Low-carbon steel, provides exceptionally high load carrying capacity, excellent

heat dissipation.

4. Copper/Tin plating thickness 0.002mm, provides good corrosion

resistance.

Recommended for applications involving intermittent operation or

boundary lubrication...

Automotive: suspension joints, kingpin assemblies and stub axles of

tucks, automobile driving joint hinges, steering and other

linkages, articulation joints, rear chassis hinges, fair leader

rollers...

Machine tool building industry: spindles in drill, grinding, and

milling machines, ram guide plates in multi-ram presses...

Agricultural equipment: gearbox, clutch, bale trips and wheel

caster swivels for bale accumulators, front axle pivot bearings,

steering idler box bearings and kingpin bearings for harvesters...

It is especially well-suited for applications where lubricant can

not be supplied continuously or repeatedly.

High load capacity

Excellent impact resistance and self-centering performance

Excellent anti-pollution performance

Good friction and wear resistance

Good resistance to chemical corrosion

Good dry friction performance

POM is a triple layer bearing consisting of a copperplated steel

frame, a middle layer of sintered bronze, and a self-lubricating

sleeve bearing surface of acetal plastic (POM).

The self-lubricating sleeve bearing surface is provided with grease

pockets which embeds the lubricant for gradual

release during operation. The slip layer also has a good ability to

embed dirt and small particles that could damage the shaft. POM can

withstand relatively high loads and is suitable for rotary and oscillating movements and

structures with frequent starts and stops.

POM self-lubricating sleeve bearing are not to be worked on (no bore or grinding). Nor on the inside

or the outside diameter. They are already prepared for assembly.

The bearings are so designed that when press-fitting the bearing

into the housing, the mating gap can be eliminated. However, the

mating-point of the self-lubricating sleeve bearing should be

positioned away from the load-zone.

Always cut or stick the sliding plate (sheets or washers) from the

sliding surface towards the steel surface. self-lubricating sleeve

bearing is to be cut from the inside towards the outside. This is

to prevent the three layers from dividing. Therefore always start

from the soft layer towards the harder layer.

It also helps you to keep any burrs in the right direction (not

towards the sliding surface).

Please don´t hesitate to contact us if further information is

needed.

self-lubricating sleeve bearing, washers, or sheets of the brand POM-self-lubricating sleeve bearing are pre-lubricated, and therefore lubrication

through grease or oil is to recommend. Through adding oil-resin

into the POM-mix, our POM-steel sleeve bearing bushings are

actually capable of running a while ”dry”, without breaking. Any

type of grease, oil, or another lubricant can be used since the POM

layer is not sensitive in any way for the chemical reaction of

additives in lubricants.

On request, we can offer inch-sizes, special lengths, items acc. to

drawing

| Technical data | |

| Material: | Steel frame/sintered/acetal resin sliding layer |

| Standard: | Multilayer bearings |

| Sliding layer (thickness): | 0.3-0.5mm |

| Tensile strength Rm: | - |

| Yield strength Rp 0.2: | - |

| Elongation in % A10: | - |

| Hardness: | - |

| The coefficient of friction | 0.05-0.25µ |

| Thermal conductivity: | 40W/m·K |

| Temperature range: | -40°C/110°C |

| Max. load static: | 140N/mm² |

| Max. load, dynamic: | 70N/mm² |

| Max. sliding speed (w.lubr.): | w/o lubricate. 2.5m/s – With lubricating. 5m/s |

| Pv-value, Mpa x m/s, | 3 |

| Counter material | |

| Recommended shaft hardness: | >180HB |

| Rec. shaft surface roughness (Ra) | 0.4 |

| Recommended tolerance: | f7/h8 |

| House: | H7 |

DIN ISO can be used to select the appropriate size to replace the same size grease-lubricated copper sleeve

-- Suitable for dirtyand| as well

as challenging environments

-- maintenance(pre-lubricated).

-- Long life

Areas of use.

Forest, packaging and, farming, machinery

food market, hydraulic cylinders, etc

Shapes

Plain cylindrical bearings, thrust washers well as sliding plates.

VIIPLUS offers a variety of services to our global customer base that will enhance the experience of purchasing valves Bushing & Bearings from VIIPLUS and add value to your investment from pre-sales consultancy to continuous aftersales service.

VIIPLUS self-lubricating sleeve bearing Material provides high-end casting to our valve divisions including materials like (low temperature) carbon steel/ stainless steel/ PTFE Bushing POM Bushes and high bronze alloy steels self-lubricating sleeve bearing. All analyses regarding the mold and pattern designs are being performed in our own premises in order to guarantee a constant casting level and quality.

VSB-20 Boundary self-lubricating sleeve bearing High-Quality POM Bush China Manufacturer

· marginally self-lubricating sleeve bearing for grease or

oil lubricated applications

· Standard parts contain grease indents in the sliding layer; plain

sliding layer available by request

· Optimum performance under relatively high loads and low speeds

· Suitable for linear, oscillating and rotating movements

· Wide range of parts available from stock

Suitable for rotating and oscillating movement, fewer maintenance requirements due to the long re-lubrication intervals, lower wear, lower susceptibility to edge loading, no absorption of water and therefore no swelling, good damping behaviors, good resistance to shock loads.

It is recommended to be used for initial grease self-lubricating sleeve bearing. This material has good wear resistance and can be used under medium and high load, impact and dust resistance conditions. Such as truck or commercial vehicle axle, brake, suspension system, as well as agricultural machinery, forest machinery, logistics equipment, and other general industrial plain bearings, can replace the general copper sleeve, steel sleeve.

1. POM thickness 0.30~0.50 mm. It provides high wear resistance and low friction even with the only minute volume of lubricant are supplied, this self-lubricating sleeve bearing surface carries a pattern of circular indents which should be filled with grease on assembly of the bearing.

2. Sintered bronze powder thickness 0.20-0.35mm. A special

composition of powdered copper is thermally fused to the steel

backing. This contact layer acts as an anchor for the PTFE layer

and conducts the thermal build up away from the self-lubricating

sleeve bearing surfaces.

3. Low-carbon steel.Setting the foundation of the self-lubricating sleeve bearing, the

steel back provides exceptional stability, load carrying, and heat

dissipation characteristics.

· Metal-Polymer Composite Bushing Material

· Steel Back + Porous Bronze Sinter +

POM with self-lubricating sleeve bearing Indents

OPERATING PERFORMANCE | |

Dry | Poor |

Oil-lubricated | Good |

Grease lubricated | Very Good |

Water lubricated | Poor |

Process fluid lubricated | Poor |

Max. load | Static | 250N/mm2 |

Dynamic | 140N/mm2 | |

| Rotating oscillating | 60N/mm2 |

Max. speed | Dry | 2m/s |

Lubrication | >2m/s | |

Max. PV (Dry) | Short-time | 3.6N/mm2*·m/s |

Continuous | 1.8N/mm2*·m/s | |

Temp. | -195℃~+280℃ | |

Friction coefficient Dry | 0.03~0.20 | |

Lubrication | >2m/s | |

Thermal conductivity | 42W (m·k)-1 | |

Coefficient of thermal expansion | 11*10-6k-1 | |

self-lubricating sleeve bearing forms available in standard

dimensions

· Cylindrical bushes

· Thrust washers

· Sliding plates

Metric self-lubricating sleeve bearing and imperial bushings made

to order: standard bushing forms in special dimensions,

half-bushings, special shapes obtained by stamping,

self-lubricating sleeve bearing with locating notches,

self-lubricating sleeve bearing holes and machined grooves,

customized self-lubricating sleeve bearing designs

START YOUR PROJECT WITH AN APPLICATION ENGINEER

Plain Bearings & Self-lubricating Bushings | VIIPLUS Surface Engineering|Bearing Technology

Bushings, Lubricated Bearings, Composite Bearings, Metal Bearings, Compressor Bearings, Metal-polymer, Filament Wound, Plain Bearings, Flange Bearings, Polymer Bearings, Flange Bushings, Pump Bearings, Flanged Bushes, Plates, Industrial Bearings

Pom Coated Bearing, Metal-Polymer Composite Bearing, Manufacture, Wholesale