POM Composite Thrust Washer for Valve refers to a component made of

Polyoxymethylene (POM), a type of engineering plastic, that is

specifically designed to function as a thrust washer in a valve

system. A thrust washer is a type of flat washer that is used to

provide a smooth surface for the transmission of thrust loads or

pressure. In valve applications, the POM composite thrust washer

helps to evenly distribute the load and reduce friction between

moving parts, ensuring smooth and reliable operation of the valve.

POM, also known as acetal, is a thermoplastic polymer with

excellent mechanical properties, including high strength,

stiffness, and abrasion resistance. It is often used in

applications requiring durability and dimensional stability. The

composite material, which typically combines POM with other

materials like fillers or reinforcements, further enhances the

properties of the base material, making it suitable for demanding

applications like valves.

The specific design and dimensions of the POM composite thrust

washer for a valve will depend on the requirements of the valve

system, including the operating pressures, temperatures, and the

type of media flowing through the valve. Proper installation and

maintenance of the thrust washer are crucial to ensure the

long-term performance and reliability of the valve.

Bushing, Thrust Washer Wall Thickness, Self-lubricating

Bronze Bushing, Ptfe Coated Bushing, Bush, Bearing,

Manufacturer China, Exporter ChinaREQUEST FOR QUOTATION

Select 2020 high quality Bushing products in best price from

certified Chinese Bearing manufacturers.

Oilless POM steel SF2 sliding Plates poriferous bushings washer

Customized various carbon steel Washer | VSB-20

Chinese high performance bearing solutions High quality Thrust

slide washer PTFE, from VIIPLUS, premium brand

VIIPLUS Self-Lubricating Bearings Material provides high-end

casting to our valve divisions including materials like (low

temperature) carbon steel/ stainless steel/ PTFE Bushing POM Bushes

and high bronze alloy steels bearings.

Tuyst Washers

Our viiplus bearing THRUST WASHER / ROUND / COMPOSITE / POM &

PTFE range of POM coplymer washers is ideal for a range of

application across many industries and are extremely versatile.

They benefit from having excellent sliding properties, a good

temperature range, are physiologically inert and are lightweight.

They also have a high impact strength and excellent resilience.

VIIPLUS Provide non-standardized products:Cylindrical bushes,

thrust washers, strip and non-standard parts as the clients

supplied drawing etc.

TYPICAL APPLICATIONS

Packaging Machinery Packaging Bushings

We provide bearings solutions for packaging machines,

pick-and-place robots and product inspection robots for a variety

of industries including, food and beverage, chemical manufacturing,

and pharmaceuticals.

Our main production of plastic packaging machinery bushings.

VIIPLUS also operation of printing machinery bushings, plastics

machinery bushings, food machinery bushings.

Noise jamming for packaging machinery is very harmful.

Adopting viiplus made self-lubricating bearing, moving smoothly in

a low noise.

The abnormal noises produced in the running of low noise sliding

bearings are the serious quality problems. As viiplus bushings,

there was no need to add lubricating oil, and low noise.

We are committed to sliding bearing product innovation through

state-of-the-art equipment, engineering expertise and extensive

research and development; allowing us to provide creative bearings

solutions.

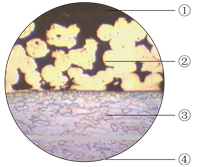

CHARACTERISTICS

Metal-Polymer Low Friction Plain Bearings

Steel + Bronze Powder + PTFE/Fibre

Self Lubricating Bearings Low-Carbon Steel + Porous Bronze + Red

PTFE

VSB-40 low friction bushings offer good wear and low friction performance

over a wide range of loads, speeds and temperatures in dry running

conditions

· Very good performance in lubricated applications

· Good performance in greased applications

· Suitable for linear, oscillating and rotating movements

Suitable for dry running, low coefficient of friction, lower wear,

good sliding characteristics, the transfer film created can protect

the mating metal surfaces, suitable for rotating and oscillating

movement, high chemical resistance, low absorption of water and

swelling. The VSV-40 improved the friction and much good wear

resistance over the common CSB-10 range under lubricated operation.

1. PTFE/Polymer fibres mixture thickness 0.01~0.03mm. Lead-free

bearing layer provides an excellent initial transfer film, which

effectively coats the mating surfaces of the bearing assembly,

forming an oxide type solid lubricant film.

2. Sintered bronze powder thickness 0.20-0.35mm, provides max.

thermal conductivity away from the bearing surface, also serves as

a reservoir for the PTFE mixture.

3. Steel backing, provides high load carrying capacity, excellent

heat dissipation.

4. Copper/Tin plating thickness 0.002mm, provides good corrosion

resistance.

TECHNICAL DATA

STRUCTURE & COMPOSITION

· Metal-Polymer Composite Bushing Material

· Steel back + Porous Bronze Sinter +

· PTFE + Fillers

| Sliding layer

PTFE + Fillers

Porous Bronze Sinter

Steel Backing

|

Tech. Data

Max. load | Static | 250N/mm2 | Max.speed | Dry running | 0.08~0.20 |

Very low speed | 140N/mm2 | Hydrodynamicoperation | 0.02~0.08 |

Rotatingoscillating | 60N/mm2 | Frictioncoefficient | Dry | 2m/s |

Hydrodynamic | >2m/s |

Max. PVdryrunning) | Short-termoperation | 3.6N/mm2*m/3 | Thermal conductivity | 42W(m*K)-1 |

Continuousoperation | 1.8N/mm2*m/3 |

PV max. hydrodynamic | -195℃~+280℃ | Coefficient of thermalexpansion | 11*10-6*K-1 |

OPERATING PERFORMANCE |

Dry | Good |

Oil lubricated | Very Good |

Grease lubricated | Good |

Water lubricated | Fair |

Process fluid lubricated | Good |

viiplus provides a complete set of sliding bearing solutions for hydraulic system users. The supplied products include: gear pump aluminum seat

assembly, axle sleeve, side plate; Blade pump and plunger pump with

oil plate, return disk, axle sleeve; Cylinder liner and so

on.

Bearing forms available in standard dimensions

· Cylindrical bushes

· Flanged bushes

· Sliding plates

· Thrust washers

· Flanged washers

Metric bearings and imperial bushings made to order: Standard

bushing forms in special sizes, half-bushings, stamped/deep drawn

shapes, bearings with locating notches, lubricant holes and

grooves, customized designs

Bushings,Lubricated Bearings,Composite Bearings,Metal

Bearings,Compressor Bearings,Metal-polymer,Filament Wound,Plain

Bearings,Flange Bearings,Polymer Bearings,Flange Bushings,Pump

Bearings,Flanged Bushes,Thrust Plates,Industrial Bearings