Zhengzhou Sinolion Equipment Co., Ltd |

|

organic Fertilizer Rotary Drum Dryer For Drying chicken manure

| INTRUDUCTION FOR ROTARY DRYER | |

| Brief Introduction | Rotary dryer is widely used to dry materials in industries like cement, mine, construction, chemical, food, compound fertilizer, etc. Thermocouples are installed in feeding and discharging units to control temperature. Temperature change of the dryer also can be indicated by the thermometer, which is convenient for temperature control inside the dryer ( it is usually 250-350℃). |

| Applications | Powder & particle: Sands, limestone, stones, clay, mineral filter cake, coal, iron

sulphate, filter cakes, fly ash, gypsum etc. Damp and sticky material: Coal slime, sewage sludge, bentonite, Kaolin etc. Corrosive material: Distillers ‘grains, Fertilizer, animal dung, slag etc. Biomass material: Sawdust, wood chips etc. |

| Features | 1.International standard with ISO, CE certificate. |

| 2.Simple system, safe and easy operation. | |

| 3.Flexibility in fuels used (NG, Oil, Coal ect.). | |

| 4.Year of experience with all types of dryers. | |

| 5.Capable of installation anywhere in world. | |

| 6.In house engineering for custom fit applications. | |

| 7.Proven design. | |

Sawdust dryer is preferred products for drying sorghum, coconut, bagasse, pellet production line and other various drying engineering such as sawdust, apple pomace, wood chips, etc. And sawdust dryer is also widely used for drying materials in industries like cement, mine, building materials, chemistry, food and fertilizer, etc. This sawdust dryer comes with thermocouples on the feeding and discharging device to control the temperature.

When drying sawdust, wood shavings, rice bran, wood chips and other materials, it is necessary to consider a very important issue, that is, the material in the drying process to avoid burning. Our rotary dryer uses multi-tube indirect drying, and the materials are in indirect contact with hot air, which can effectively solve the problem of material burning.

1. New technology of indirect-drying structure, the working process is very safe and health.

2. Biofuels stove, has a high environmental protection effect.

3. High thermal efficiency, the thermal efficiency can reach 60%.

4. Multi-tube structure to avoid material agglomeration and uniform drying.

5. Construction investment reduces 50%, power consumption reduces 60%.

6. Adopts roller rotation, no need reducer.

7. Hot air stove can supporting fluidezed bed, spray stove, hands burned furnace, also used in fuel and gas type, can bake the below 20 mm pieces of materials, aggregates, powder material.

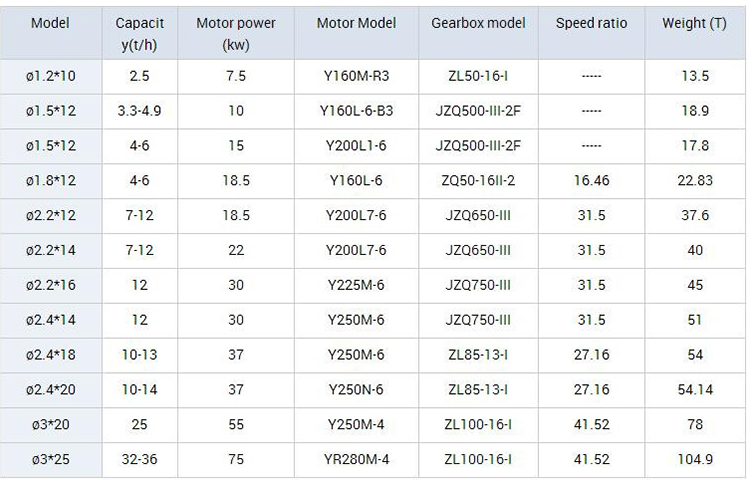

Technical parameters

Our advantages

1. Can customize products according to customer requirements.

2. Four standardized production lines, adequate stocking.

3. 15 years of R&D experience.

4. CE, ISO, Soncap Certificated.

5. Resource chain integrity, strong ability to integrate resource

Contact us: