Hubei Yideli Light Industry Technology Co., Ltd. |

|

3500L Electric Heating 4 Vessel Brewhouse With Dimple Plate Jacket For Fermentation System

Beer Brewing Equipment Description

Our product includes a variety of large, medium and small brewery

equipment, hotel, bar home-brewed beer equipment, teaching

experiment etc. And could be used to brew various types of wine,

beer, barley-bree (whisky) brandy. We supply brewing of main and

auxiliary raw material, technical training, secondary equipment and

control equipment, of course, can customize according to customer

required special specifications design, production, installation of

equipment and other products.

Brewhouse Configuration

The brewhouse system could be included two-vessels brew house,

three-vessels brew house and four-vessels brew house.

2 Vessel Brewhouse

Mash /Lauter Tun + Boil Kettle/Whirlpool Tun

Mash/Lauter Tun/Hot Liquor Tank Combi vessel + Boil Kettle/Whirlpool Tun

Mash/Lauter Tun + Boil Kettle/Whirlpool + Hot Liquor Tank

3 Vessel Brewhouses

Mash/Lauter Tun + Boil Kettle + Whirlpool Tun

Mash(kettle) Tun + Lauter Tun + Boil Kettle/Whirlpool Tun

4 Vessel Brewhouses

Mash(kettle) Tun + Lauter Tun + Boil Kettle + Whirlpool

5 Vessel Brewhouses

Mash Tun + Lauter Tun + Boil Kettle + Whirlpool+ Holding Kettle

Standard Features

Desiging tanks and heating system according to craft, mash tank

warming≥10ºC/min

Energy saving stir structure : large cross-section impeller,

15r/min speed

Sieve plate of filter tank includes welding sieve plate and milling

sieve plate.

Plow knife of filter tank separated to one foot, feet and bow plow

knife

Wort boiling heat way includes steam jacket, interior heating and

exterior heating.

Material includes stainless steel 304, 316 and red copper.

Technial Parameters

| Daily Output | 300L | 500L | 600L | 800L | 1000L | 2000L | 3000L | 5000L |

| Unit Type | EH300 | EH500 | EH600 | EH800 | EH1000 | EH2000 | EH3000 | EH5000 |

| Floor Space | 25m² | 45m² | 55 m² | 70m² | 80m² | 120m² | 150m² | 250m² |

| Height | 2060mm | 2700mm | 2700mm | 2750mm | 2810mm | 3500mm | 4000mm | 4300mm |

| Power | 20KW | 35KW | 35/15KW | 35/15KW | 35/15KW | 65/15KW | 65/15KW | 65/15KW |

| Electrical | 3P 380V(220V, 110V, 415V...) 50(60)HZ; 1P 220V(120V,110V,240V...) 50(60)HZ | |||||||

Equipment Advantage

1. Top cone of all tanks are mirror polished.Beer brewing equipment

micro brewery 100L, 200L, 300L 500L, 1000L per batch

2. Flanging butt joint on manway pipe fittings, beautiful and

secure weld joints.

3. Outer cladding is adopted mechanical polished with uniform

welding lines.

4. Our skilled workers are with more than 10 years welding and

related production experiences.

5. High quality milled falsed bottom installation method: special

discharging hangle, easy to discharge and clean;

6. Led cold light, bright , lower power consumption and lasting,

other suppliers only use normal light ball;

7. Imported food grade rubber hose, long lift-span, safe and firm.

8. Large spent grain door, reliable sealing, with hopper, easy to

make the spent grain out without ground pollution

9. Mechanical pressure adjustable valves: plus and minus pressure

protection, ensure the tank safty.

10. Complete quality control and management system: material IQC

complete inspection, PQC production process inspection,OQC

inspection after finishing production brewhouse installation 24

water leakage test and pressure test, fermenters cooling jacket

pressure 24 hours test.

11. 1 Years After-sales services for our goods.

12. Complete beer line to meet different capacities and all kinds

of beer

13. Customize machine can be

offered(voltage,material,dimension,heating source and so on)

System Specs:

Standard 4-Vessel Brewhouse configuration

Working Platform / Heat Exchanger

Large working platform

All stainless steel anti slip design

Built in work shelf

Spray down hose location

Full handrails

Heat Exchanger: SU304 plate and frame 4 sq meter surface area

Control Panel

Centralized control panel

Temperature displays for all critical process

VFD controls for Pumps and rake

Burner controls

Lighting controls

Integrated circuit breakers

Utility Connections

Electricity: 220VAC/208VAC 3-Phase for mash rake, wort pumps, and

main control panel. 30 Amp breaker required.

Water: 1" NPT female inlets at Brew House for hot and cold water

sources.

Gas Pipe Size: Minimum 3/4", larger sizes may be required due to

distance from meter and pressure drop.

Gas pressure required: 7" W.C (water column) minimum 14" W.C.

maximum at burner location.

Photos:

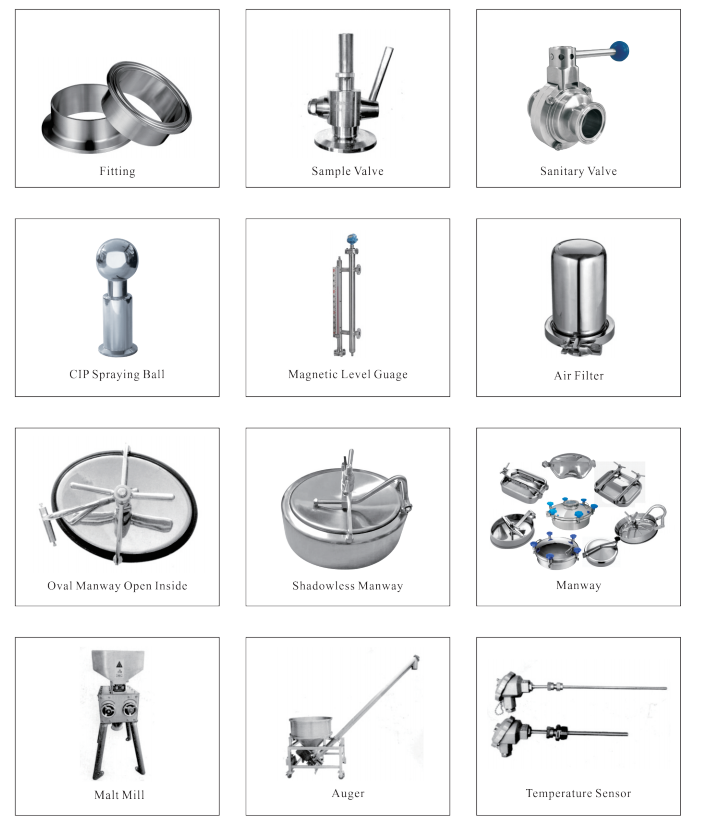

Accessories: