Suzhou Jingang Textile Co.,Ltd |

|

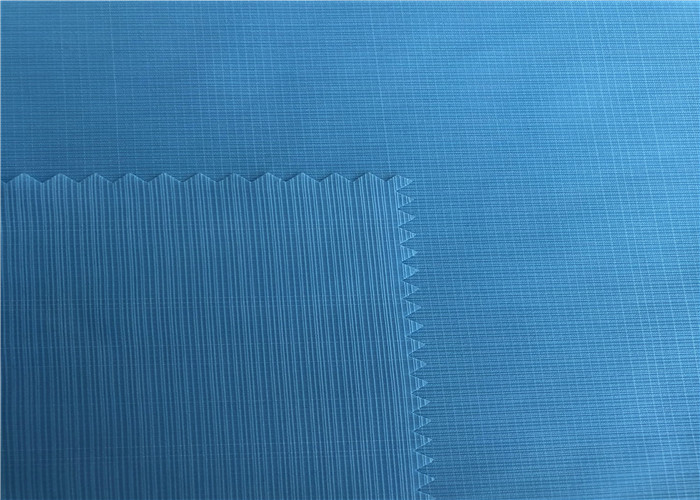

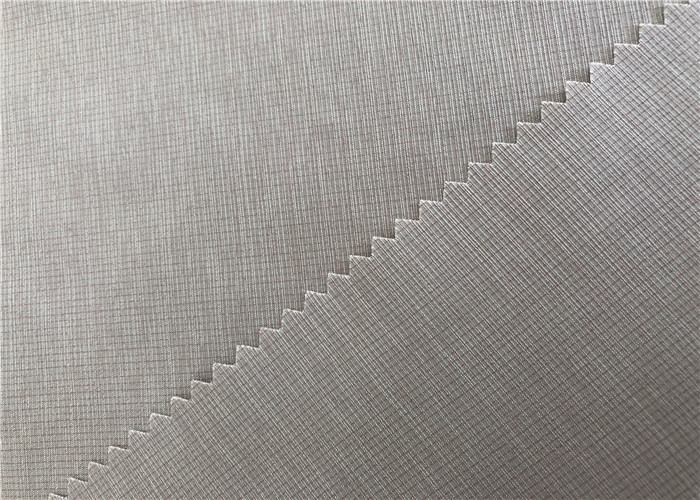

Irregular Ripstop Fade Resistant Polyester Coated Waterproof Outdoor Fabric For Skiing Jacket

1 . Descriptions:

If you stop and rest in the wild after a large amount of exercise, it may be because the outside temperature is low and the sweat cannot escape in time to form water droplets on the inner layer of the clothes, which makes people feel very uncomfortable. Now this fabric can help you solve this problem.

This fabric is 100% polyester.The yarn count is 50D+50D*30D+150D. We finish this fabric dyed and coating.So this fabric is waterproof and has shape handfeel. According to your special requirements, we can do many finishing like bonding, cire,lamination and etc.Also this fabric has many choices of color.

2 . Specifications:

| Name | Irregular Ripstop Polyester Coated Waterproof Outdoor Fabric |

| Material | 100%P |

| Backing | Dyeing+Coating |

| Weight | 86 GSM |

| Width | 57/58'' |

| Color | various colors available |

| Standard | can meet REACH,ROHS,EN71-3 |

| MOQ | 1000m |

| Packaging | by rolls as 50m or according to your requirements,polybags,vacuum packing |

| Payment term | T/T |

3 . How to Solve the "Condensation" Phenomenon:

If you stop and rest in the wild after a large amount of exercise, it may be because the outside temperature is low and the sweat cannot escape in time to form water droplets on the inner layer of the clothes, which makes people feel very uncomfortable. This is called " Condensation" phenomenon. There is a special moisture permeable finishing process called “low condensation”, which uses polyurethane (PU) and hydrophilic nano-ceramic powder to coat the fabric and absorb it when the body evaporates a lot of sweat. More sweat vapor, thus avoiding the phenomenon that the water vapor inside the clothes exceeds the saturated vapor pressure and is converted into water droplets.

In addition to the methods of fiber and coating, it is also possible to absorb moisture perspiration on the fabric structure. For example, a two-layer structure is adopted, the inner layer of the body is made of hydrophobic fibers, and the outer layer is made of hydrophilic fibers, so that the sweat can be transferred from the skin to the inner layer fibers by capillary action, and then the outer layer is hydrophilic. The binding force between the fiber and the water molecule is stronger than that of the inner layer, and the water molecule is again transferred from the inner layer of the fabric to the outer layer and finally released into the atmosphere.

4 . About Test:

5 .More pictures: