Suzhou orl power engineering co ., ltd |

|

Oil-fired ISO9001 SA516GR70 Boiler mud drum with Natural Circulation

Boiler Mud Drum

Description

In the water tube boiler the upper drum (Boiler steam drum) provides for separation of steam from water. It also provides liquid holdup capacity (typically 10 to 60 seconds) to allow for a dynamic response to load changes without losing liquid in the downcomer and riser tubes. The size of the steam drum is determined by the volume required for a clean separation between steam and water to produce a dry saturated steam, it also provides an adequate amount of steam storage. The steam drum is also called the upper drum.

Product parameter

| Product Name | Boiler Steam Drum ( Steam Water Separator ) |

| Applied Area | Natural circulation boiler |

| Drum Shell Plate Material | - Carbon Steel : Q245R, P265GH, SA516-Gr.60/65/70 - Alloy Steel : Q345R, Q375R, 15CrMoR, 12Cr1MoVR, P355GH , DIWA353 |

| Drum Head Material | Same as shell |

| Nozzle Tube Material | As per design |

| Standard | China GB, ASME, EN |

| Manufacturer Grade | China A Grade, ABS Certificated, TUV Certificated |

| Working Temperature | Saturation Temperature at rated pressure |

| Working Pressure | 1.6 MPa ~ 22.5 MPa |

Shell Plate Thickness (Drum Wall Thickness) | ≤150 mm |

| Drum Diameter | ≤3,200 mm |

| Drum Length | ≤25,000 mm |

| Welding | - Shell : SMAW, SAW - Nozzle tube : GTAW (TIG), SMAW |

| Welding NDT | - Shell longitudinal seam : 100% RT, 100% UT - Shell circumferential seam : 100% RT, 15% UT - Nozzle tube angle seam : 100% UT, 100% MT |

Boiler Drum,Boiler Waterwall Panel,Boiler Economizer,Boiler Header,Boiler Cyclone Separator,Boiler Chimney Flue Pipe,Boiler Air Preheater

1. High technical content, self insulation cylinder body, 80%

thermal efficiency.

coal saving is 68% than single-cylinder dryer and output increases

100%

2. The length is good for technical layout, 60% shorter than single-cylinder dryer.

Also it’s about 20m³area, reducing plant area and saving 40% investment

3. Adopt heat resistant and wear resistant steel plate, 4 times

wear resistant than the general steel plate, long service time and

convenient to maintain.

4. Outside cylinder body temperature is below 60°(single cylinder

temperature is up to 150°), with low outlet temperature.

5. Low outlet temperature is good for keeping long service life.

6. Electic consumption reduce 60%

7.Adopt roller rotation, without large and small gear

| Name&Type | Supply Ability: | FOB Price |

| Boiler drum | 100Ton/Tons per Month | Contact Me Get Latest Price |

| Boiler header | 100Ton/Tons per Month | Contact Me Get Latest Price |

| Boiler waterwall panel | 500Ton/Tons per Month | Contact Me Get Latest Price |

| Boiler economizer | 500Ton/Tons per Month | Contact Me Get Latest Price |

| Boiler super heater | 300Ton/Tons per Month | Contact Me Get Latest Price |

| Boiler air preheater | 300Ton/Tons per Month | Contact Me Get Latest Price |

| Other | 300Ton/Tons per Month | Contact Me Get Latest Price |

Boiler Parts

Boiler Super Heater,Boiler High Temp Superheater,Boiler Cyclone Separator,Boiler Flue,Boiler Heat Pipe Air Preheater,Boiler Gen Bank,Boiler Heat Pipe Elements,Boiler Tube Pin,Boiler Tubeshield,Boiler Ditch Tube

Suzhou ORL Power Engineering Co., Ltd.is located in Suzhou, Jiangsu Province.

ORL Power is a leading company and exporter of industrial boilers,power plant boilersand boiler parts (including steam drum, membrane waterwall panel,header,economizer, evaporator, superheater,H-fin economizer, spiral fin tube, air preheater, heat pipe, flue etc.), seamless steel tubes/pipes and ERW steel pipes.ORL provides our customer with full range of services including boiler design, fabrication, installation and commissioning, boiler maintenance, and supervision at site. Our product and service include design and manufacture industrial boilers, pressure vessels and tanks, and pressure parts for power plant boilers (600MW, or 1000MW).

Company Information

Product Description

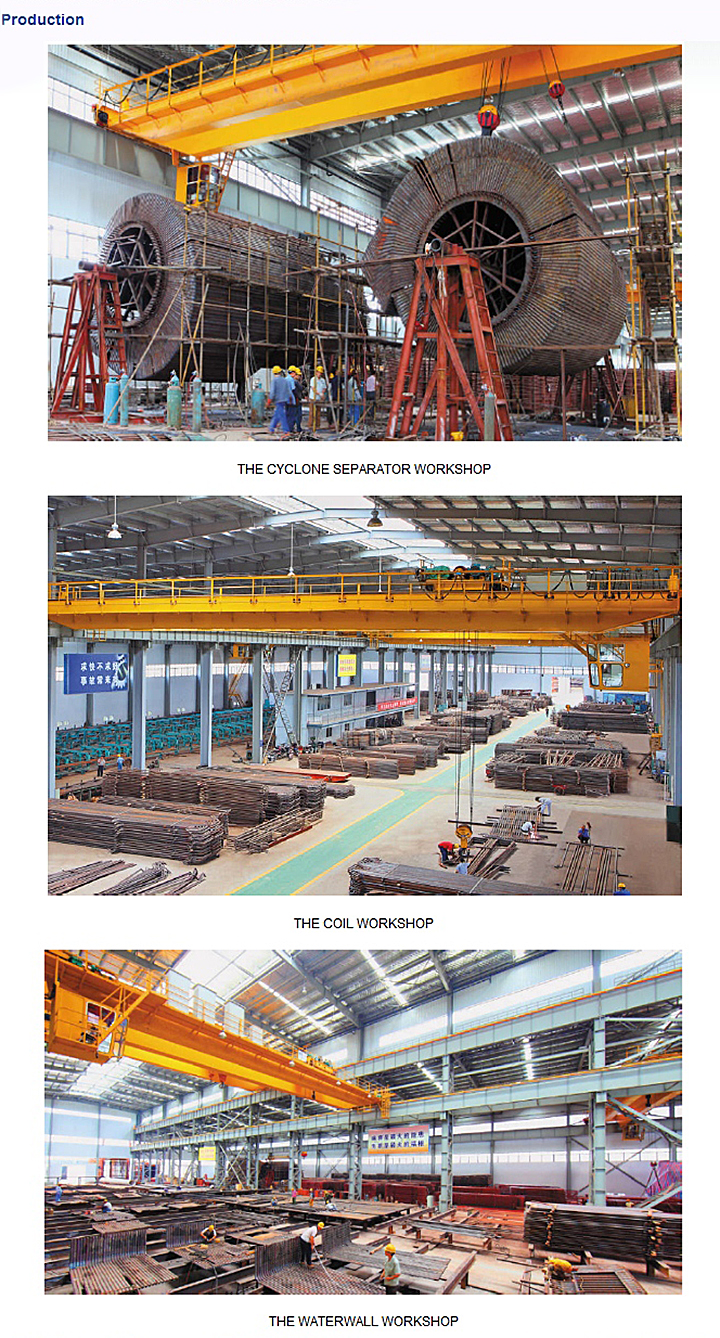

Production Workshop

Boiler Product Production

Boiler Cyclone Separator WorkShop, Boiler Coil Workshop, Boiler Waterwall Workshop.

Testing Center

Boiler Product Test

Impact test,The scene to examine the water-wall,Industrial TV monitoring,Snake-like pipe water pressure test,Header endoscopic detection,Header weld inspection

Packaging & Shipping

Certifications

Company Business

Our products have been wildly used in power plants and large international companies overseas.

Such as USA, Brazil, Porto Rico, Guatemala, Spain, Demark, Norway, Turkey, India, Korea, Australia, Middle East, Southeast Asia etc.

We have our boiler manufacturing plant, and obtain ISO9001:2008, ISO3834, ASME S, U and GB stamp.

Trading Process

ORL offers prompt response, professional products, and all-around service to our customers. Our experienced sales team and engineers are waiting for your enquiry and ready to provide sincere service. We cordially welcome domestic and overseas friends to visit our company and manufacturing bases, and look forward to building up long-term, mutual cooperative relationship with you.

FAQ

1. Why choose us?

We are boiler and boiler parts(boiler drum, boiler waterwall panel, boiler economizer, boiler header, boiler cyclone separator, boiler flue pipe, boiler air preheater, boiler pipe, boiler tube)manufacture and we are one of the best suppliers in China.

We ensure the deliver time, high quality, and the best after-sale service for you.

2. How to order?

Welcome come to our factory for inspecting and discussion the

technical details.

Contact Information