ZHANGJIAGANG HUA DONG ENERGY TECHNOLOGY CO.,LTD |

|

Verified Suppliers

|

|

ASTM A178/ASME SA-192M Seamless carbon Steel Pipe For Boiler pressure parts

Hua Dong Energy Technology exports steel boiler pipe(seamless steel pipe and welded steel pipe) according to the production methods, steel boiler pipe specifications with overall dimensions (such as the diameter or length) and the wall thickness, steel boiler pipe can be used in the pipeline, thermal technology equipment, industrial machinery, petroleum geological exploration, containers, chemical industry, and other special purpose.

| Carbon | Chromiun | Low Temperature | Stainless Steel | Duplex | Copper& Bronze | Titanium | Ni-Alloy | ||

| SA178-A | SA213-T1 | SA333-Gr.1 | SA213 | TP316L | A789-S31803 | SB111-C70600 | SB338-GR.1 | SB163 | NO2200 |

| SA178-C | SA213-T11 | SA333-Gr.3 | SA249 | TP316H | A789-S32205 | SB111-C71500 | SB338-GR.2 | SB167 | NO2201 |

| SA179 | SA213-T12 | SA333-Gr.6 | SA268 | TP316Ti | A789-S32750 | SB111-C71640 | SB338-GR.5 | SB444 | NO8020 |

| SA192 | SA213-T22 | SA333-Gr.7 | SA269 | TP316LN | A789-S32760 | SB111-C68700 | SB338-GR.7 | SB514 | NO6022 |

| SA209-T1 | SA213-T5 | SA333-Gr.8 | SA376 | TP321 | A789-S32707 | SB111-C44300 | SB338-GR.9 | SB619 | N10276 |

| SA209-T1a | SA213-T9 | SA334-Gr.1 | TP304 | TP321H | A789-S32304 | SB338-GR.12 | SB622 | NO4400 | |

| SA209-T1b | SA213-T91 | SA334-Gr.3 | TP304L | TP347 | A789-S31500 | SB626 | NO6600 | ||

| SA210-A1 | SA334-Gr.6 | TP304H | TP347H | S31254 | SB674 | NO6601 | |||

| SA210-C | SA334-Gr.7 | TP304N | TP405 | 254MA | SB677 | NO6625 | |||

| SA214 | SA334-Gr.8 | TP310H | TP409 | 17-4PH | SB704 | NO690 | |||

| SA513 MT 1010 | TP310S | TP410 | 17-7PH | SB705 | NO8800 | ||||

| SA513 MT 1015 | TP309S | TP430 | 15-7PH | N1001 | NO8810 | ||||

| SA513 MT 1020 | TP317 | TP439 | N10665 | NO8811 | |||||

| TP317L | TP444 | N10675 | NO8825 | ||||||

| TP348 | TP446 | TP904L | |||||||

| TP347HFG | |||||||||

| Tube Sizes for Heat Exchangers & Condensers & Boiler | |||||||||

| Outside Diameter | BWG | ||||||||

| 25 | 22 | 20 | 18 | 16 | 14 | 12 | 10 | ||

| Wall Thickness mm | |||||||||

| 0.508 | 0.71 | 0.89 | 1.24 | 1.65 | 2.11 | 2.77 | 3.40 | ||

| mm | inch | Weight kg/m | |||||||

| 6.35 | 1/4 | 0.081 | 0.109 | 0.133 | 0.174 | 0.212 | |||

| 9.53 | 3/8 | 0.126 | 0.157 | 0.193 | 0.257 | 0.356 | 0.429 | ||

| 12.7 | 1/2 | 0.214 | 0.263 | 0.356 | 0.457 | 0.612 | 0.754 | ||

| 15.88 | 5/8 | 0.271 | 0.334 | 0.455 | 0.588 | 0.796 | 0.995 | ||

| 19.05 | 3/4 | 0.327 | 0.405 | 0.553 | 0.729 | 0.895 | 1.236 | ||

| 25.4 | 1 | 0.44 | 0.546 | 0.75 | 0.981 | 1.234 | 1.574 | 2.05 | |

| 31.75 | 1 1/4 | 0.554 | 0.688 | 0.947 | 1.244 | 1.574 | 2.014 | 2.641 | |

| 38.1 | 1 1/2 | 0.667 | 0.832 | 1.144 | 1.514 | 1.904 | 2.454 | 3.233 | |

| 44.5 | 1 3/4 | 1.342 | 1.774 | 2.244 | 2.894 | 3.5 | |||

| 50.8 | 2 | 1.549 | 2.034 | 2.574 | 3.334 | 4.03 | |||

| 63.5 | 2 1/2 | 1.949 | 2.554 | 3.244 | 4.214 | 5.13 | |||

| 76.2 | 3 | 2.345 | 3.084 | 3.914 | 5.094 | 6.19 | |||

| 88.9 | 3 1/2 | 2.729 | 3.609 | 4.584 | 5.974 | 7.27 | |||

| 101.6 | 4 | 4.134 | 5.254 | 6.854 | 8.35 | ||||

| 114.3 | 4 1/2 | 4.654 | 5.924 | 7.734 | 9.43 | ||||

ASTM A213/ASME SA213 T2, T11, T12, T22, T91, T92 Chemical Composition and Mechanical Properties

| Grade | Chemical Composition% | ||||||||

| C | Si | Mn | P, S Max | Cr | Mo | Ni Max | V | Al Max | |

| T2 | 0.10~0.20 | 0.10~0.30 | 0.30~0.61 | 0.025 | 0.50~0.81 | 0.44~0.65 | – | – | – |

| T11 | 0.05~0.15 | 0.50~1.00 | 0.30~0.60 | 0.025 | 1.00~1.50 | 0.44~0.65 | – | – | – |

| T12 | 0.05~0.15 | Max 0.5 | 0.30~0.61 | 0.025 | 0.80~1.25 | 0.44~0.65 | – | – | – |

| T22 | 0.05~0.15 | Max 0.5 | 0.30~0.60 | 0.025 | 1.90~2.60 | 0.87~1.13 | – | – | – |

| T91 | 0.07~0.14 | 0.20~0.50 | 0.30~0.60 | 0.02 | 8.0~9.5 | 0.85~1.05 | 0.4 | 0.18~0.25 | 0.015 |

| T92 | 0.07~0.13 | Max 0.5 | 0.30~0.60 | 0.02 | 8.5~9.5 | 0.30~0.60 | 0.4 | 0.15~0.25 | 0.015 |

| Grade | Chemical Composition% | Mechanical Properties | |||||||

| W | B | Nb | N | T. S | Y. P | Elongation | Hardness | ||

| T2 | – | – | – | – | ≥ 415MPa | ≥ 205MPa | ≥ 30% | 163HBW(85HRB) | |

| T11 | – | – | – | – | ≥ 415MPa | ≥ 205MPa | ≥ 30% | 163HBW(85HRB) | |

| T12 | – | – | – | – | ≥ 415MPa | ≥ 220MPa | ≥ 30% | 163HBW(85HRB) | |

| T22 | – | – | – | – | ≥ 415MPa | ≥ 205MPa | ≥ 30% | 163HBW(85HRB) | |

| T91 | – | – | 0.06~0.10 | 0.03~0.07 | ≥ 585MPa | ≥ 415MPa | ≥ 20% | 250HBW(25HRB) | |

| T92 | 1.50~2.00 | 0.001~0.006 | 0.04~0.09 | 0.03~0.07 | ≥ 620MPa | ≥ 440MPa | ≥ 20% | 250HBW(25HRB) | |

| Outside Diameter | OD Tolerance | WT Tolerance | Ovality Tolerance | Cut Length Tolerance |

| OD≤ 12, 7 mm | ± 0, 13 mm | ± 15 % | – | + 3, 18 mm, – 0 mm |

| 12, 7 mm < OD ≤ 38, 1 mm | ± 0, 13 mm | ± 10 % | max, 1, 65 mm | + 3, 18 mm, – 0 mm |

| 38, 1 mm < OD ≤ 88, 9 mm | ± 0, 25 mm | ± 10 % | max, 2, 41 mm | + 4, 76 mm, – 0 mm |

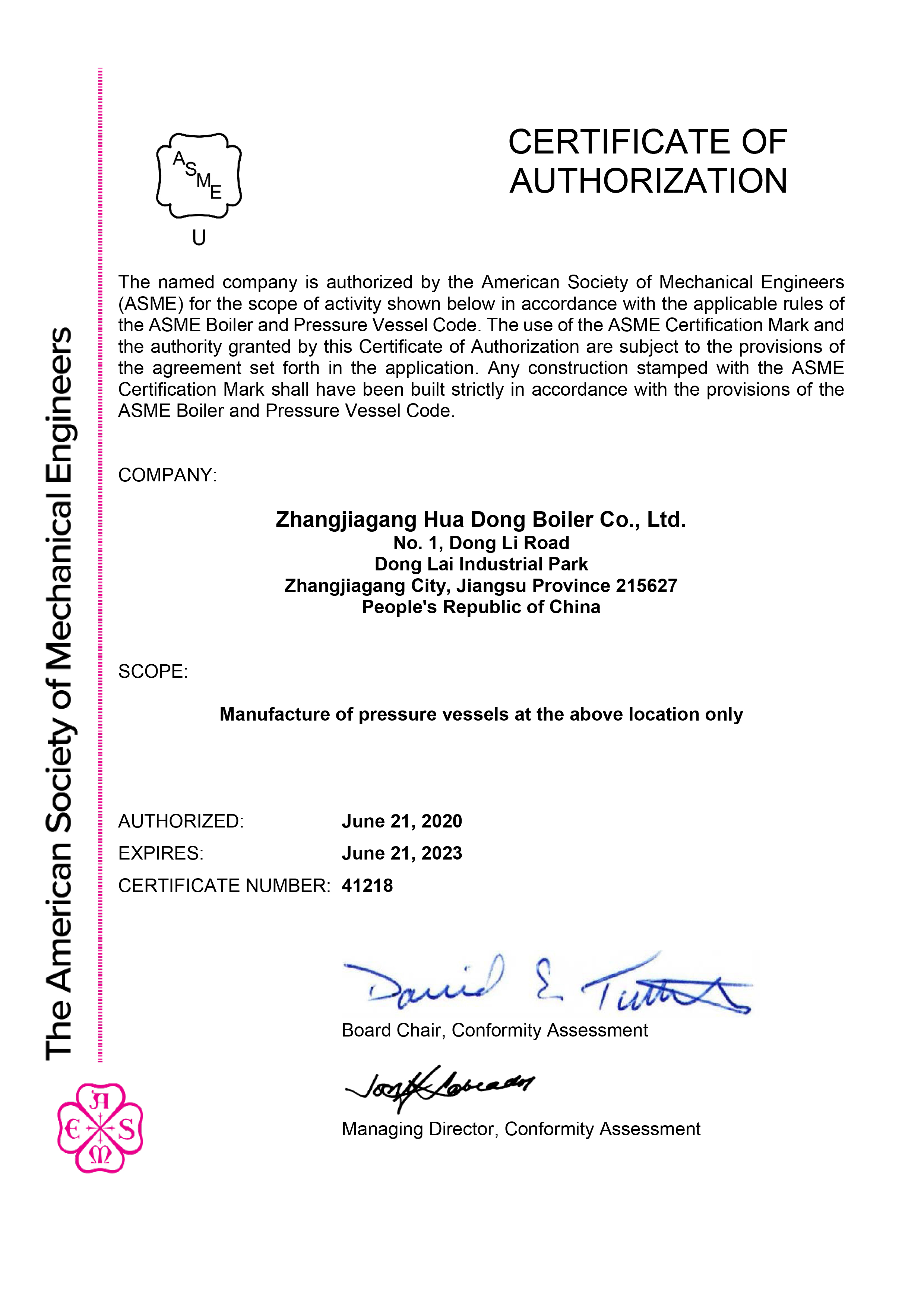

Certification