Zhangjiagang HuaDong Boiler Co., Ltd. |

|

Verified Suppliers

|

|

General Introduction: Air Preheater

Air preheater, or boiler preheater, is an important boiler part. It

can be divided into two kinds, Tubular type air preheater and

Vertical type air preheater.

Air preheater pipe type, mainly using industrial furnaces or smoke

waste heat boiler combustion air preheating furnace enter, such not

only improves the thermal efficiency of the stove and reduce the

environment pollution.

Take the rotary type as a example to illustrate the working

principles of air preheaters, when under operation, it would be

slowly rotating, and exhaust gas will enter the gas flue side of

air preheater, and then be dicharged. The heat carried by the gas

flue will be absorbed by the cooling ribs of the air preheater,

then the air preheater will be rotating slowly, the cooling ribs

work to the side of the air, delivering the heat to the air before

the air enters the boiler.

The air preheaters applied in boilers are mostly three warehouses

type with fire alarm system, internal adjustment system and

frequency conversion control system. It is convenient to use air

preheaters with easy operation and safe running, meanwhile it can

improve the performance of heat transferring of the bouler system,

thus it is very common to apply air preheaters in the system of

boiler gas flue.

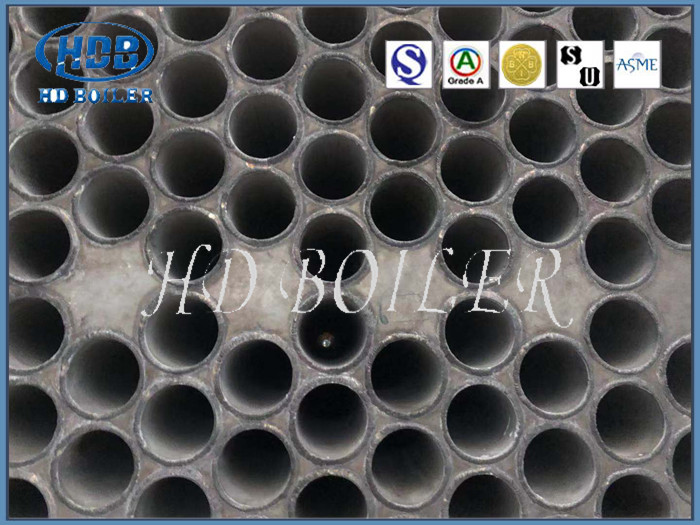

Details

The main heat transfer component of tubular air preheater is thin-walled steel tube. The tubular air preheaters are mostly cubic. The steel tubes are arranged vertically and staggered with each other. Both ends are welded on the upper and lower tube sheets.The tubular air preheater is equipped with an intermediate tube sheet in the tube box. The flue gas passes through the preheater up and down the pipe, while the air passes through the preheater horizontally to complete heat transfer.

Tubular air preheater is widely used in power station boilers and industrial boilers because of its advantages of good sealing, high heat transfer efficiency, easy manufacturing and processing. The shortcomings of tubular air preheater are large volume, easy ash plugging of steel tube content, difficult cleaning and easy wear and tear at flue gas inlet.

Parameter

Layout item | Horizontal layout | Vertical layout |

| Tube arrangement | staggered arrangement / | staggered arrangement / |

| Sealing of pipe and plate | Packing heat- resistant material/ | welding |

| Anti-wearing | a,when gas scours external tube, welcoming smoke tubes have

protective tile | |

Enamel air preheater products are classified as following by

application

1.Enamel heat exchanger designed for denitration renovation

projects

2.Enamel heat exchanger for circulating fluidized bed boiler and

pulverized coal boilers Heat

exchanger parts for garbage incinerators and biomass boilers

3.Heat exchanger parts for grate furnaces, like chain grate

furnaces4.Heat exchanger parts for gas-fueled boilers, such as

kerosene boilers, coke ovens, etc.