Zhangjiagang HuaDong Boiler Co., Ltd. |

|

Verified Suppliers

|

|

ASME Certification Energy Saving Boiler Parts Air Preheater For Power Plant Boiler

Description

The air preheater is a heat exchanger that uses the flue gas heat from the rear of the boiler to heat the air needed for combustion.The tube and tube plate can be sealed with heat resistant packing, and can be sealed by welding.Customers can choose according to their own needs.

1. A device,which increases the tempurature of air before it supply to the furnance using heat from flue gases passing through chimney.

2. The heat carried with the flue gases coming out of economiser is further utilised for preheating the air before supplying to the combustion chamber.

3. An increase of 20 degree centigrade in the air temp.increases the boiler efficiency by1%.

4. It is a necessary equipment to supply hot air for drying the coal in pulverised fuel systems to facilitate grinding and satisfactory combustion of fuel in the furnace.

Benefits

1. Improved combustion rate and then increases steam generations rate of boiler.

2. Due to higher temperature of air, furnance temperature increases, so low grade coal can be burnt efficiently.

3. Air heated by heat of exhaust gases.It reduces fuel consumptions.Therfore thermal efficiency of boiler increased.

4. Saving in fuel consumption and Increased steam generation capacity.

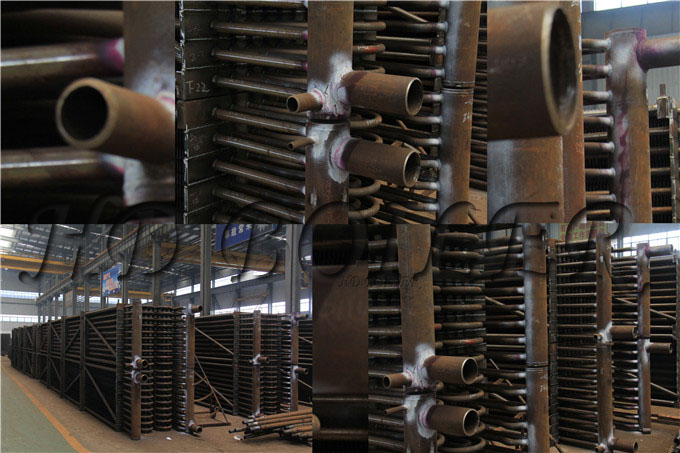

Tubular air preheater

Our factory specialise in tubular air preheaters.Tubular air preheaters may have a number of configurations.

1. A bundle of vertical tubes through which the flue gas flows

downward and exchanges heat with ambient air flowing horizontally

across the exterior of the tubes. Baffles are usually provided so

that the air flows across the tubes a number of times. For example,

as shown in the adjacent diagram, the air flow across the tubes

three times and is referred to as 3-pass tubular air preheater.

2. The same as (1) above except that the flue gas flows upward

rather than downward.

3. A bundle of horizontal tubes through which the air flows and

exchanges heat with the hot flue gas flowing downward across the

tube bundle.

Adavantages

1. Preheated air increases combustion rate and then increases steam generations of boiler.

2. Due to higher temp. of air,furnace temp.increases,so low grade coal can be burnt efficiently.

3. Air heated by heat of exhaust gases.It reduces fuel consumptions.Therefore thermal efficiency of boiler increased.

Construction

An air preheater is installed between economisers and the chimney.It consists of large numberss tubes which arranged in the path flue gases shell.Inlet air is at lower end.Baffles are provided inside air preheater.The soot hopper is provided at the bottom.

Working process

1. Hot flue gases enters into tubes from the top of the shell and leaves from to the chinmney.

2. The inlet air at R.Tem. is admitted into the shell with the help of the fan.

3. The air passes upward around the tubes in the opposite direction to the flow of the hot gases.

4. Baffeles increases the total path length of air thus increase heat transfer.

Testing