Zhangjiagang HuaDong Boiler Co., Ltd. |

|

Verified Suppliers

|

|

Stainless Steel Factory Supplier Finned Tube Economizer for Steam Boiler

Product Description

| 1 | Boiler economizers reuse exhausted flue gas to pre-heat the feedwater entering the boiler. |

| 2 | Essentially a mini-heat exchanger, economizers improve boiler performance while increasing fuel efficiency. |

| 3 | By rapidly increasing feedwater temperature through captured flue

gas, economizers also provide a significant improvement in steam

generation and response time. |

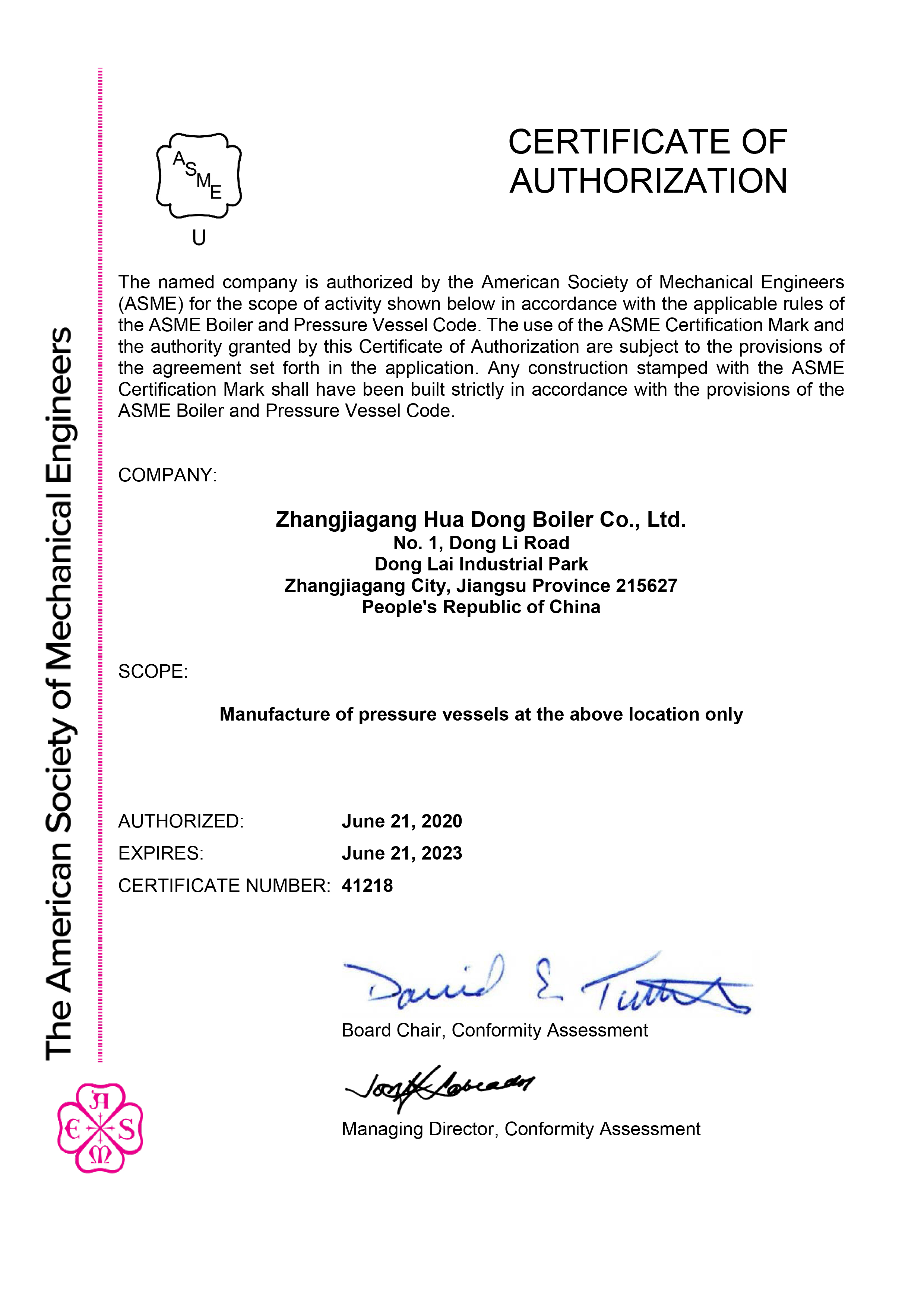

Certification

Technical specifications

Material Structure

Consists of a serious of spiral fin tubes, the headers of inlet and

outlet, bend, frame and other auxiliaries.

Structure Arrangement

In line / staggered arrangement.

Characteristics

| 1 | This type of economizer can largely develop the heat exchanging area than the bare economizer to add the heat transfer area, reduce the volume, compact structure and reduce the number of elbow and welding to make less leakage and add the heat transfer efficiency. |

| 2 | Not easy to collect dust and the fume pass through the fin tube to form the boundary layer to occur the vortex to make less chance for the fly ash particle to touch the tube wall. |

| 3 | Widely temperature range, high pressure limit. |

| 4 | Durable strong impact, reliable operation. |

| 5 | less fume resistance, reduced abrasion and long working life. |

| 6 | Beautiful appearance, simple fabrication process. |

| 7 | Diverse layout. |

| 8 | Ease of installation, ease of construction. |

| 9 | A wide range of working pressure . |

Manufacturing and acceptance criteria

| 1 | JB/T6512 "boiler with a high-frequency resistance welding spiral fin tube manufacturing technology conditions" |

| 2 | HG/T3181 "high-frequency resistance welding spiral fin tube" |

| 3 | JB/T6511 "spiral finned tube test technical conditions." |

| 4 | JB1611 "boiler tube mane box assembly conditions" |

| 5 | JB/T1612 "boiler pressurufacturing conditions." |

| 6 | JB16I3 "boiler pressure parts welding conditions." |

Parameters

| Name | Economizer |

| specifications of finned tube | unit(mm) |

| Bare pipe(od) | 25-165 |

| bare pipe(thick) | 2-8 |

| finned thicks | 0.6-3.0 |

| finned height | 5-30 |

| finned tube thread pitch | 5-30 |

| finned tube length | ≤12000 |

*Note:HD BOILER can bespoke special type of economizer according to

customer's requirement.

Quality Control

| 1 | Impact test and Strength calculation report with applied materials information. |

| 2 | 100%NDT(non-destructive inspection) report of steel plate, tube and electrode. |

| 3 | X-ray, γ-ray and liquid penetrant test inspection report (welding seam): to ensure the quality of the entire boiler. |

| 4 | Hydraulic test report: ensure the standard working pressure and safety. |