Zhangjiagang HuaDong Boiler Co., Ltd. |

|

Verified Suppliers

|

|

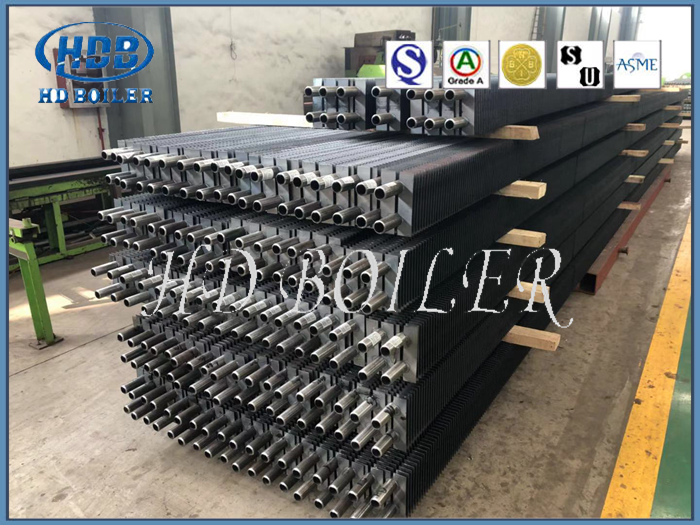

Stainless Carbon Steel Fin Tube Heat Exchanger For Power Plant Economizer

Product Description

Fin tubes is an important part of boiler for utility/power stantion plant.

Our products include Fin Tube,Extruded Fin tube,Welding Fin tube,L/LH Type Fin Tube,H Type Fin tube with Material A179/Alu1060,stainless steel,copper,copper nicke and so on.

Concrete parameters as below:

| Technical parameters | The high degree of fin 0-16mm(or outside diameter of fin φ25-φ75); Pitch of fins 2.0-5.0mm; Length of finning tube 0.5~ 14m. |

| Single metal rolling finning tube | Pure aluminum 1060 or aluminum alloy 6063,6061. Outside diameter Shall be less than 40mm |

| Double metal rolling finning tube | Tube-based protection from the outer layer of aluminum tubes,corrosion-resistant,Tube-based can be made of carbon steel pipe,in addition to,stainless steel tube and copper tube can also be used, as well as titanium alloy tube |

| Package | The aluminum finned tubes are well packed in plastic film in the

inner and steel fram in the outer |

Advantage

1.Increase the heat transfer area outside the pipe

The fin tube extends the heat transfer area outside the light tube, and the convection heat transfer surface is composed of the extended surface and the light tube surface. Under the same shape size, the heat transfer area is much larger than that of the light tube, thus significantly improving the heat transfer capacity on the outside of the tube and the heat transfer efficiency of the coal saver.

2. Rounding of heat exchanger structure

The fin tube bundle increases the heat transfer area in the volume of the unit body, and reduces the volume of the heat exchanger when the heat transfer is the same.

3. Enhance heat transfer conditions

Fins to form small labyrinth of flue gas velocity field is a high middle and low on both sides, and the influence of the temperature field, small flue middle velocity will be higher, can increase air flow disturbance between fins, cause the flow boundary layer separation and cycle development, and thinning fins on the flow boundary layer and thermal boundary layer, shorten the length of flow boundary layer, helps to destroy the boundary layer of laminar sublayer, which have the effect of strengthening heat transfer.

4. Reduce the flow resistance of the fluid outside the pipe

In the direction of the fins and scouring of the airflow direction of fin parallel case, although the staggered fins bundles per row of ventilation resistance is about 1.2 times of the light pipe, under the same conditions, but in the dimension of tube bank fin is relatively light tube bundle each row of the increase of heat exchange area is far greater than 1.2 times, thus can reduce the number of tube bundle row, making the decrease in the total heat exchanger Yin force.At the same time, as the heat transfer capacity of the fin tube is greatly improved, the fluid velocity outside the tube can be appropriately reduced under the condition of ensuring the heat transfer capacity, while the flow resistance is generally proportional to the square of the velocity, so reducing the fluid velocity can reduce heat exchanger resistance and save operation cost.

Reduce heating surface wear

When the gas-solid two-phase fluid scours the heating surface, when the solid particles imbedded in the flow flow through the heat exchanger surface, the impact and cutting heat exchanger surface will cause the wear of the heating surface, and the wear amount is directly proportional to the cubic square of the fluid velocity.As the heat transfer capacity of the fin tube is improved, the velocity of the fluid outside the tube can be reduced and the wear of the heating surface can be greatly reduced.At the same time, the structure characteristics of the fin tube can enable the fluid flowing through the fin tube to form flow conditions conducive to reducing wear to a certain extent, thus weakening the numeral damage caused by the impact and cutting of small solid particles on the heating surface.

Specifications

In order to ensure that these units met customer expectations, a series of in-process testing was performed in accordance with Fin Tube Products' quality control system. In addition, the products' quality was also verified by an onsite independent testing company.

Base Tube Material | Stainless Steel, Carbon Steel, Alloy Steel, Copper Alloy,Aluminum

,SA179 | ||

Fin Material | Aluminum, Copper Alloy, Stainless Steel, Carbon Steel | ||

Standard | ASME SA213/ASTM; ASME EA 106, ASME SA178, ASTM B1111 | ||

Fin depth | 0.5-3mm | ||

Base pipe O.D | 12.7-18mm | ||

Fins per inch | 8-20Nos (as customer's request) | ||

Test Requirement | Physical Property Test, Chemical Composition Analysis,

Non-Destructive Test, Other Inspection and Test as customer's

requirement. | ||

Application | Air Cooler, Charge Air Chiller, Condenser, Evaporator, Fluid

Cooler, Gas Cooler, Oil Cooler, Radiator, Refrigeration, Steam to

Air Heat Exchange, super heater etc. | ||

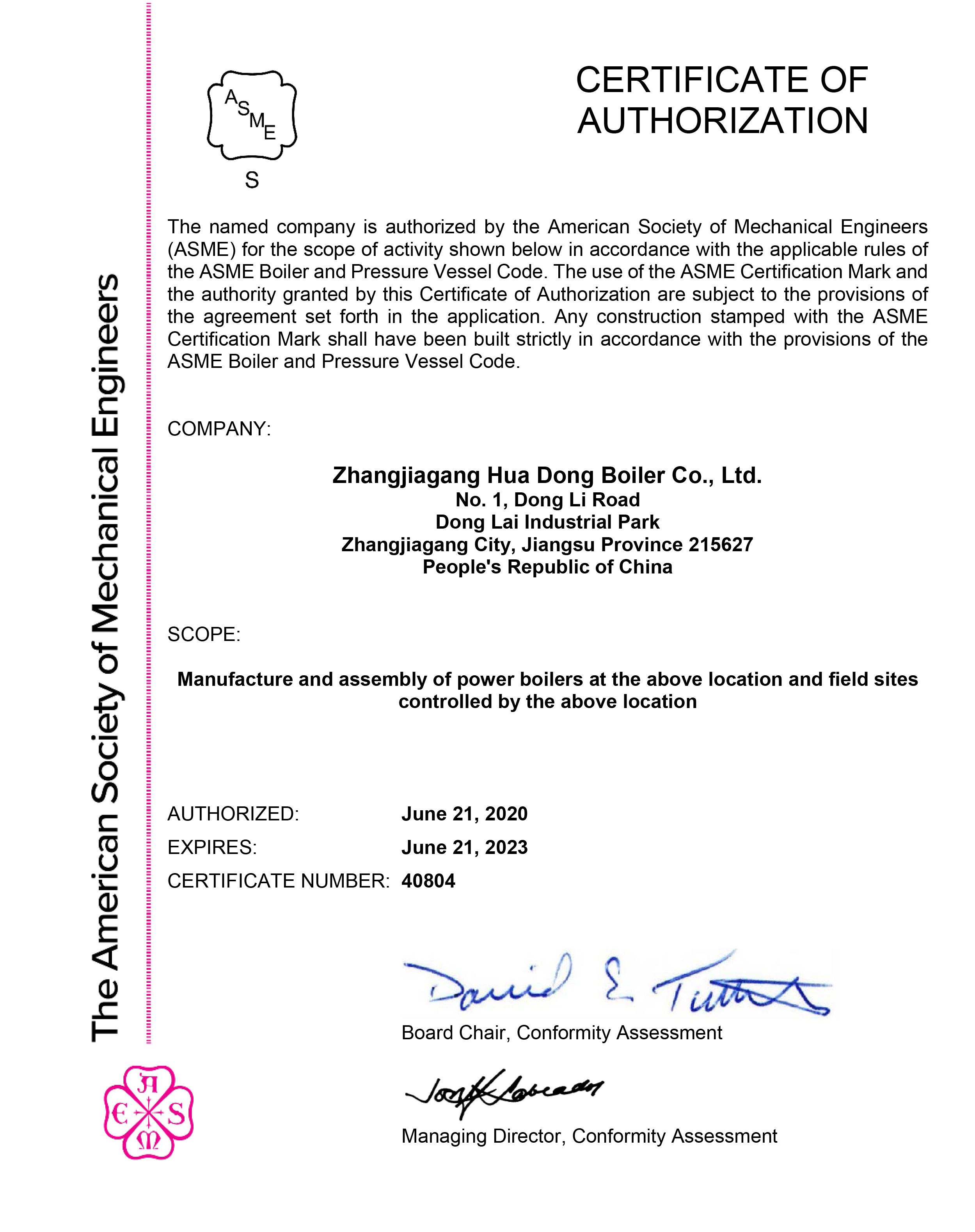

Certification