Jiangsu Faygo Union Machinery Co., Ltd. |

|

High Speed Beverage Plastic Container Making Machine , Bottle Blow Moulding Machine

Product specification

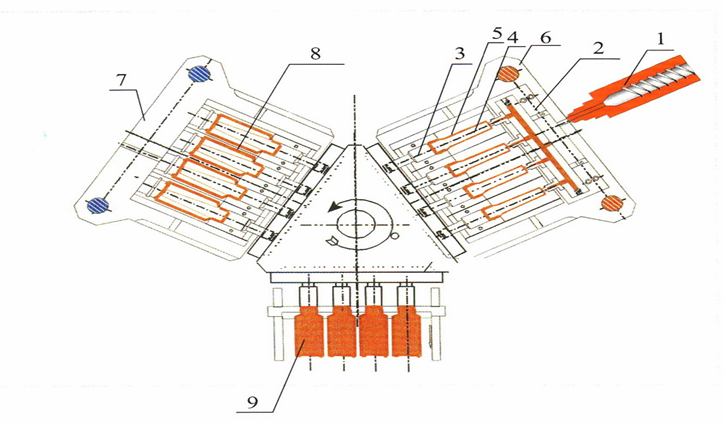

The machine is a full automatic injection molding equipment, suitable for processing PP, PS, PE, SAN,PMMA, PC, PETG, PEN and other thermoplastic, widely used in pharmaceutical, health care products,food and beverage, cosmetics, etc..One Mold with Multi-cavities for automatic continuous production technology, using three horizontal station rotary device, hot runner system and multi-stage injection molding system,injection molding, blow molding, demolding three position and action to ensure equipment of high efficiency and energy saving operation, ensure smooth product bottle, the bottleneck of inner and outer diameter and thread high precision, no waste is the standard equipment of modern enterprise environment-friendly production.

Equipment Productive Flow Sheet

1, STOCK PREPARATION/INJECTION DEVICE

2, HOT-FLOW CHANNEL

3, ENTIRE BAR

4, BOTTLE BLANK

5, INJECTION MOLD

6, INJECTION STATION

7, BLOW STATION

Mode cavity number control table

| Product Size | FG40 | FG60 | FG80 | FG100 | |||

| Volume | Neck Dia. | Height | Body Dia. | Cavities | Cavities | Cavities | Cavities |

| 5ML | 10 | 35 | 45 | 9 | 14 | 18 | 22 |

| 10ML | 12 | 40 | 20 | 9 | 12 | 16 | 20 |

| 20ML | 15 | 50 | 25 | 8 | 10 | 14 | 18 |

| 30ML | 20 | 60 | 30 | 7 | 9 | 13 | 16 |

| 40ML | 22 | 65 | 35 | 7 | 8 | 12 | 15 |

| 60ML | 28 | 75 | 40 | 6 | 8 | 12 | 14 |

| 80ML | 30 | 80 | 45 | 5 | 7 | 10 | 13 |

| 100ML | 32 | 85 | 50 | 4 | 6-7 | 10 | 12 |

| 150ML | 35 | 90 | 53 | 3 | 5-6 | 8 | 9 |

| 200ML | 38 | 100 | 58 | 3 | 4-5 | 7 | 8 |

| 400ML | 42 | 120 | 65 | 2 | 3-4 | 6 | 7 |

| 650ML | 50 | 160 | 80 | 1 | 2 | 5 | 6 |

| 800ML | 40 | 200 | 90 | 1 | 2 | 4 | 5 |

| 100ML | 45 | 200 | 90 | 1 | 2 | 3 | |

Product parts

Detailed Images

YUKEN pump and valve;

SEALTECH O-rings & seals;

Advanced servo motor

Rotation system, ejection system and flipping system adopt advanced

servo motor,can improve preformance stable, also save 40% energy.

Delivery pictures