WENZHOU HUALE MACHINERY CO.,LTD |

|

Aluminum Aluminum Automatic Blister Packing Machine / Blistering Machine

Can make both ALU-ALU and ALU-PVC

DPP-140E

Model | ALU-ALU | ALU-PVC | |

Machine Body Material | SS 304/316 | ||

Blanking frequency(times/min) | 15-30 | 20-45 | |

Adjustable pulling length | 30-120mm | ||

Blister Size | Design According To Customers’ Requirements | ||

Max Forming area and depth(mm) | 140*110*12 | 140*110*15 | |

Air compressor(self-prepared) | 0.6-0.8Mpa ≥0.4m3/min | ||

Mould cooling | (Recycle water or circulating water consumption) 40-80 L/h | ||

Power supply(Three phase) | 380V/220V 50HZ 3KW

| 380V/220V 50HZ 5.5KW

| |

Wrapper specification (mm) | Alu Alu Foil 150*(0.14-0.18)*(Φ400) | PVC 150*(0.15-0.4)*(Φ400) | |

Aluminum Foil:150*(0.02-0.15)*(Φ400) | |||

Overall Dimension(L*W*H) (including foundation) | 2400*650*1450 | ||

Dimension of Each Part | 1350*650*1250(front) | ||

1050*650*1450(back) | |||

Weight | About 800kg | ||

Description

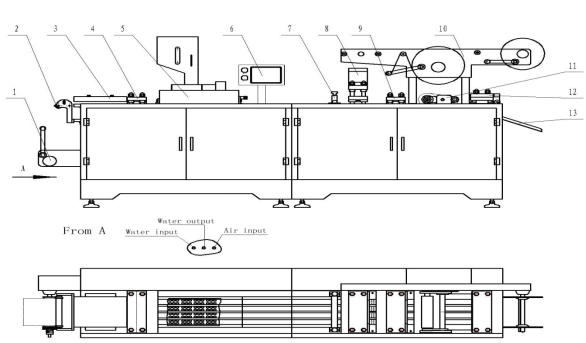

OVERALL SKETCH

1: PVC feeder 2: PVC transporting roller 3: Heating box 4: Forming mechanism(the material of punch head is PTFE)

5: Medicine feeder(The manual feeding without this station)

6: Touch-screen 7: PTP transporting roller

8: Heat-sealing mechanism 9: Trace-pressing mechanism

10: PTP feeding mechanism & scrap-collector 11: Tow mechanism

12: Blanking mechanism 13: Finished product output

Attention

When make ALU ALU product:

Turn off No.3 (Heating box),change the feeder to shaking type feeder and change molds(Forming up and

down molds, sealing up and down molds, blanking up and down molds)

When make ALU PVC product: Turn on all of the stations.

PACKAGE