Qingdao Jingcheng Weiye Environmental Protection Technology Co., Ltd |

|

Verified Suppliers

|

|

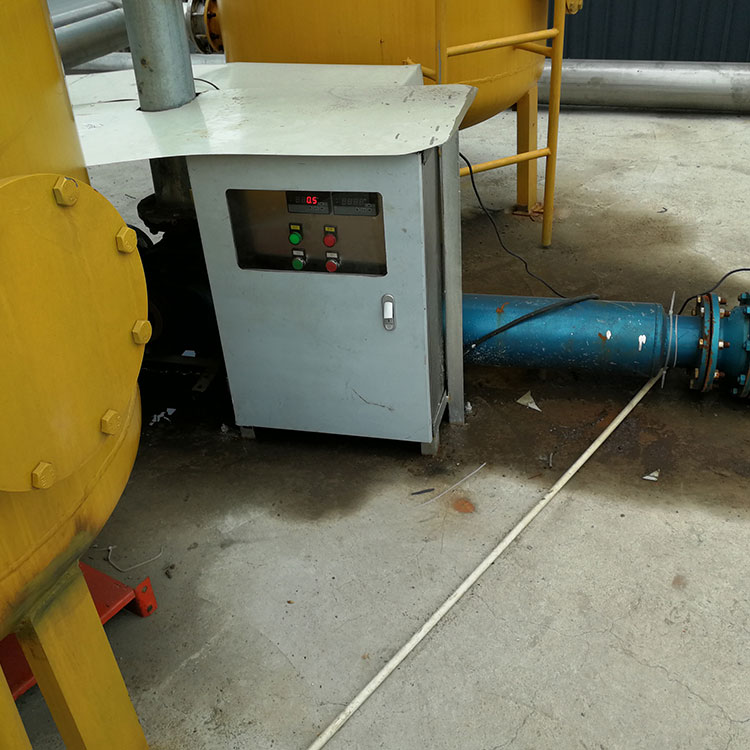

Biogas Purification Equipment Showing:

Biogas Purification Equipment Description:

Biogas Desulfurizer is designed to purify biogas by eliminating sulphur, dust, and water. It also stabilizes biogas pressure for stable and clean biogas can be utilized for biogas engine.

The main component of desulphurizer is ferric oxide (Fe2O3). After a certain amount of use, Fe2O3 will have a decreased efficiency, causing biogas to exude an unpleasant smell. It is important to replace the Fe2O3 in time.

Dry desulfurization is a practical and inexpensive method of desulfurization for biogas with less H2S concentration. Wet oxidation is the primary process of this method which works by oxidizing the H2S to sulfur oxide or sulfur.

The advantages of biogas purification equipment are obvious:

Firstly, they are easy to install and use; no personnel on duty is necessary during the working process, and materials can be regularly replaced.

Moreover, the desulfurization efficiency is high and the recycling effect could be achieved by oxidation reduction in later stage. Furthermore, it can offer finest desulfurization and high precision when it comes to the desulfurization. Additionally, the initial investment is relatively low and the operating cost is medium.

| Parameter | Details |

|---|---|

| Feature | High Efficiency, Less Than 10ppm |

| Material | Steel |

| Power Supply | Stable |

| Control system | Full Automatic Control |

| Internal treatment | Anti Corrosion Coating |

| Noise Level | Low |

| Standard | GB |

| Application | Industry Fuel, Biogas Purification |

| Desulfurization way | Dry Desulfurization |

| Advantage | Easy To Install, Recycling,Corrosion Resistance, Automatic Control |

| Product | Biogas Filtration Apparatus, Biogas Purification Apparatus, Biogas Processing Equipment |

This special equipment is mainly used for eliminating corrosive hydrogen sulfide (H2S) gas that is typically found in biogas. Additionally, it can be utilized for the purification of gas containing hydrogen sulfide, so that the treated gas is safe for normal operation and prolonged equipment lifetime.

Welcome to JCWY – The Professional Manufacturer of Biogas Purification Plant, Biogas Purifier System, and Biogas Purification System.

We offer custom-made service for our Biogas Purification Equipment, which is certified by ISO9001:2015, with a minimum order quantity of 1 set. The price ranges from USD1000 to USD50000 per set, with a normal package. We can deliver within 30-60 workdays. Payment terms include L/C, T/T. We can supply 10 sets per month. The internal treatment is anti-corrosion coating, and the power supply is stable. The material is steel, and the control system is full automatic control. The surface treatment is sand blasting and spray painting.

The biogas purification equipment is packaged and shipped in accordance with the relevant safety regulations and industry standards. All components are carefully packed in secure boxes and containers for protection during transportation.

The equipment is shipped by air, sea, or land, depending on customer needs. All shipments are carefully tracked to ensure delivery in a timely manner.

Upon delivery, customers should inspect the equipment for any damage or missing components. If any problems are found, customers should contact the manufacturer immediately.