Zhangjiagang Sunswell Machinery Co., Ltd. |

|

Verified Suppliers

|

|

General description:

3-in-1 filling monoblock, combined with rinsing, filling and

capping. It is innovated and designed in the requirement of still

pure

water and mineral water, on the bases of introducing, digesting and

absorbing advanced technology from Germany and Italy.

Equipment structure:

Base

Rotary rinser

Rotary filler

Rotary capper

Bottle infeed and outfeed system

Controlling cabinet

Technical paremeters:

Model | XGF 14-12-5 | XGF 16-16-5 | XGF 24-24-6 | XGF 32-32-8 | XGF 40-40-10 | XGF 50-50-12 | XGF 60-60-15 | XGF 72-50-18 | XGF 80-60-20 |

Capacity (BPH/500ml) | 5000 | 7000 | 10000 | 15000 | 18000 | 21000 | 24000 | 30000 | 36000 |

Details:

Rinser

Rinser

The empty bottles can be turned over 180°along the conveying rail. The machine applies unique overturning bottle clamp,which is made of SUS304. The bottle clamp grips bottle at the neck position, avoiding bottle mouth contamination. The bottle clamp equipped with high efficient spray nozzle,which spray droplet with 15° angle ,ensures to wash all side of the bottle, and can save the water. The rinser is driven by driving system inside the machine frame via gear.

Filler

Filler

Filling valves and tank are made of stainless steel SUS304 Gravity filling. Ring shape tank with float ball level control. High speed and high accuracy filling valve with 150ml/s flowing speed Bottles go up and down in the function of cam through elevator to process filling Large flat bearing inside the machine frame,stable and reliable performance.

Capper

Capper

In the screw capping part,it installed photoelectrical control,when it has no cap,or the cap is bad,the machine will stop automatically. Magnetic constant torque capping head ensures stability and controls defective rate less than 0.2%. Cap dropping rail equips a group of photoelectrical switch for reverse cap detecting.When lack of cap,machine will stopp automatically. Bottle infeed detecting switch works with the pneumatic cylinder on cap starwheel to avoid feeding cap on no-bottle condition.

Bottle infeed

Bottle infeed

Bottle infeed by combination of infeed grippers.

Equipped with bottle jam protection device.

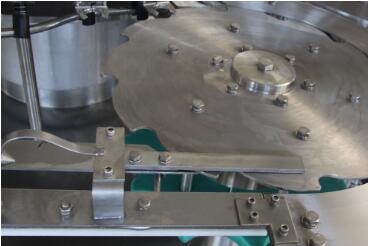

Transfer Starwheel

Transfer Starwheel

The material is super-corrosion stainless steel.

Related Products